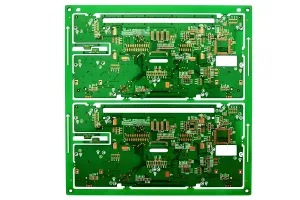

ثنائي الفينيل متعدد الكلور متعدد الطبقات

UGPCB High-Multilayer PCB Solutions: Driving Innovation in High-Density Electronic Systems through Precision Stacking Technology

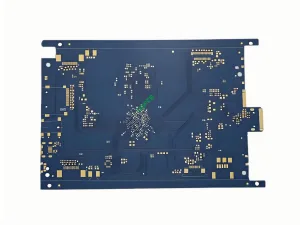

In the era of rapid advancements in 5G communication, AI servers, and high-end industrial equipment, UGPCB, with over a decade of experience in high-multilayer PCB design, إنتاج, and PCBA assembly, presents a selection of our multilayer PCB products in the “ثنائي الفينيل متعدد الكلور متعدد الطبقات” section of our corporate website. We delve into how cutting-edge processes and interdisciplinary design capabilities enable us to provide customized solutions for 8-40 layer high-density interconnect boards, high-frequency high-speed boards, and HDI PCBs, meeting stringent requirements for signal integrity, thermal stability, and long-term reliability in harsh environments.

Core Technical Advantages: Setting the Benchmark for High-Multilayer PCB Performance

-

High-Precision PCB Stackup Architecture Design

• Ultra-High Layer Count Capability: Our company has successfully mass-produced 40-layer PCB products with layer-to-layer alignment accuracy of ±25μm (using LDI laser direct imaging technology), supporting 0.1mm microvias, blind/buried vias, and Any-layer HDI.

• Hybrid Material Integration: Flexibly combining materials such as FR-4, روجرز, and MEGTRON®, we optimize Df values to 0.0015@10GHz, reducing insertion loss by 30% compared to traditional stackup solutions.

-

Signal and Power Integrity Assurance

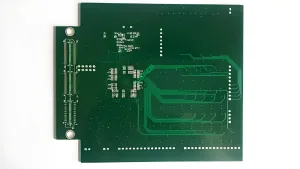

• Full-Band Impedance Control: Based on Ansys SIwave simulations, we achieve impedance tolerances of ±5% for 28Gbps high-speed signals and power plane impedances <2mΩ, meeting PCIe 5.0/USB4 specifications.

• 3D Electromagnetic Shielding: Employing stepped copper foil filling and localized ground isolation techniques, we achieve radiation noise attenuation of >55dB@6GHz, passing FCC Part 15/EN 55032 Class B certifications.

-

Thermal-Mechanical Reliability Enhancement

• CTE Dynamic Balancing Technology: By using Low CTE materials (such as TUC TU-872SLK) in the core layers to match the copper layer expansion coefficients, we ensure no delamination after 1000 thermal cycle tests (-55℃↔125℃).

• High-Thermal-Conductivity Structure Design: Incorporating 2W/mK thermal adhesive and aluminum-based heat dissipation channels, we reduce thermal resistance by 40%, ensuring stable operation of high-power ICs.

Typical Application Scenarios and Technical Parameters

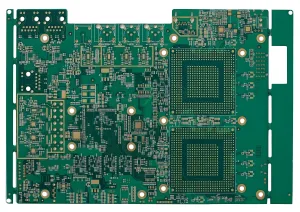

• 5G Base Station AAU Motherboard: 24-layer high-frequency hybrid PCB, combining Rogers RO4835™ and FR-4, achieving insertion loss ≤0.3dB/inch in the n260 frequency band and supporting 256T256R Massive MIMO architectures.

• Data Center GPU Accelerator Card: 32-layer high-speed PCB using MEGTRON®6 material, with 112G PAM4 signal loss <0.8dB/cm, passing OCP Open Compute Standards certification.

• Industrial Automation Main Control Board: 16-layer high-TG thick copper PCB (3oz inner layers/6oz outer layers), capable of continuous operation at 150℃, meeting IEC 61131-2 vibration/shock standards.

Full-Process Services and Certification System

• Collaborative Design Support: Providing Cadence Allegro/PADS stackup simulations, HyperLynx signal integrity analysis, and Valor DFM manufacturability verification.

• Rapid Prototyping Delivery: 5-day sample delivery for 12-layer PCBs, 10-day delivery for 20+ layer HDI boards, supporting 1-6th order laser via processes.

• Stringent Quality Assurance: 100% compliance with IPC-6012 Class 3 المعايير, ISO 9001/IATF 16949 certifications, and military-grade NADCAP qualifications covering the aerospace industry.

Reasons to Choose UGPCB

-

Technical Depth: زيادة 200 high-multilayer PCB patent technologies, with a database covering cutting-edge scenarios such as 112G high-speed/77GHz millimeter wave.

-

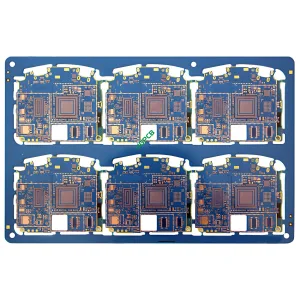

Cost Optimization: Smart panelization schemes increase material utilization by 15%, and hybrid stackup designs reduce BOM costs by 20%-35%.

-

Mass Production Assurance: Fully automated production lines achieve lamination accuracy of ±2%, with stable yield rates >99.2% for bulk orders.

Get Your Customized UGPCB High-Multilayer PCB Solution Now

Visit the relevant products under the “ثنائي الفينيل متعدد الكلور متعدد الطبقات” section of our official website, submit your requirements, and receive a free quote and technical support.

شعار UGPCB

شعار UGPCB

وي شات

امسح رمز الاستجابة السريعة ضوئيًا باستخدام WeChat