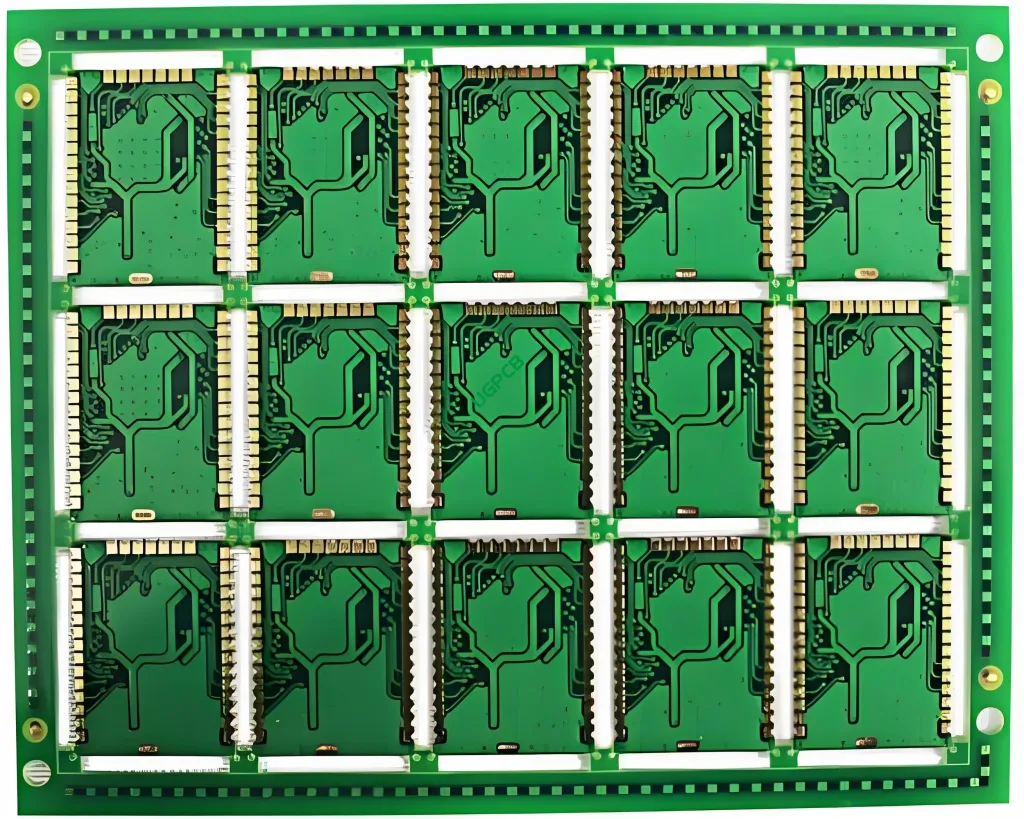

Introduction to Half Hole Car Core Multilayer PCB

Half Hole Car Core Multilayer PCBs represent a sophisticated advancement in printed circuit board technology designed to meet the demands of high-density and complex electronic applications. These PCBs are engineered with precision, combining the benefits of both standard multilayer PCBs and the unique characteristics of half hole designs to offer enhanced functionality and reliability.

Definition and Design Requirements

A Half Hole Car Core Multilayer PCB is characterized by its use of a car core—a specialized type of substrate material—that supports half holes, which are partially plated through-holes used for component leads or connections between layers. This design allows for more intricate routing and compact assembly, making it ideal for applications where space is limited. The design requirements include meticulous attention to trace width, spacing, and hole diameters to ensure optimal performance and manufacturability.

مبدأ العمل

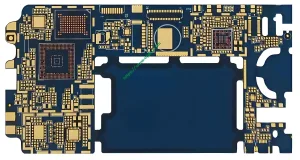

The working principle of a Half Hole Car Core Multilayer PCB revolves around the efficient conduction of electrical signals through its meticulously designed layers. Signals travel along copper traces on various layers, with half holes facilitating vertical interconnections between these layers. This architecture enables complex circuitry to be packed into a smaller footprint without compromising signal integrity or causing crosstalk.

Applications and Classification

These PCBs find extensive applications in industries requiring miniaturized yet powerful electronic systems, such as telecommunications, الأجهزة الطبية, الفضاء الجوي, and consumer electronics. They are classified based on their layer count, material composition, and specific features like immersion gold surface treatment, which enhances solderability and corrosion resistance.

Material and Performance

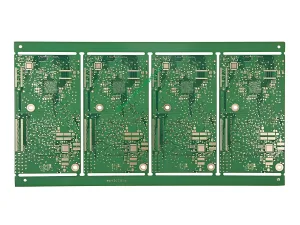

Constructed from TG170 High TG FR4 material, these PCBs boast excellent thermal stability and mechanical strength, crucial for high-performance applications. The green or white color coding aids in visual inspection during manufacturing. With a finished thickness of 0.8mm and carefully controlled inner and outer layer copper thicknesses (1OZ and 0.5OZ respectively), they offer a balance between flexibility and durability.

Structure and Features

The structure of a Half Hole Car Core Multilayer PCB comprises six layers, each serving a specific purpose in the signal transmission process. Its key feature lies in the implementation of half holes, which allow for denser component placement and reduced board size. بالإضافة إلى ذلك, the immersion gold surface treatment provides superior protection against oxidation and improves solder joint reliability.

Production Process

The production process involves several stages, including material selection, layer pressing, drilling of half holes, copper plating, and final finishing processes like surface treatment application. Advanced manufacturing techniques ensure precise control over every aspect, from trace width to hole diameter, guaranteeing high-quality outputs suitable for demanding applications.

Usage Scenarios

Half Hole Car Core Multilayer PCBs are employed in scenarios where compactness, high-speed signal processing, and reliable connectivity are paramount. They are integral components in advanced communication systems, portable medical equipment, avionics, and high-end consumer gadgets, enabling designers to push the boundaries of innovation while maintaining product reliability and performance.

شعار UGPCB

شعار UGPCB