Introduction to Type-C Connector PCB

The Type-C Connector PCB is an advanced electronic component designed for high-speed data and power transmission. This guide provides a comprehensive overview of the product, including its definition, design requirements, working principles, uses, classifications, مواد, أداء, بناء, features, manufacturing process, and typical application scenarios.

Definition

A Type-C Connector PCB (لوحة الدوائر المطبوعة) is a specialized circuit board that incorporates a USB Type-C connector. It is designed to support high-speed data transfer and power delivery, making it ideal for modern electronic devices.

Design Requirements

The design of a Type-C Connector PCB must adhere to specific standards to ensure optimal performance and reliability. Key design requirements include:

High-Speed Data Transmission

Supports USB 3.1 Gen 2 or higher standards for fast data transfer rates.

Power Delivery

Capable of handling up to 100W of power delivery, suitable for charging and powering devices.

Minimal Trace/Space

Ensures fine pitch components can be placed accurately with a minimum trace/space of 3mil/3mil.

Precision Tolerances

Maintains strict tolerance requirements for outline and PSR (Pick and Place Reliability).

مبدأ العمل

The Type-C Connector PCB operates based on the principles of electrical conductivity and signal integrity. It utilizes copper traces embedded in a high TG FR4 substrate to transmit signals between the Type-C connector and other electronic components on the board. The immersion gold and OSP surface treatments enhance conductivity and protect against oxidation.

Uses

Type-C Connector PCBs are used in a variety of applications where high-speed data transfer and power delivery are essential. Common uses include:

Data Transfer

Facilitates quick and efficient data transfer between devices such as laptops, smartphones, and external storage devices.

Power Supply

Provides reliable power delivery for charging batteries and powering electronic devices.

Device Connectivity

Enables connectivity between various devices, enhancing the functionality and versatility of electronic systems.

Classifications

Type-C Connector PCBs can be classified based on several criteria:

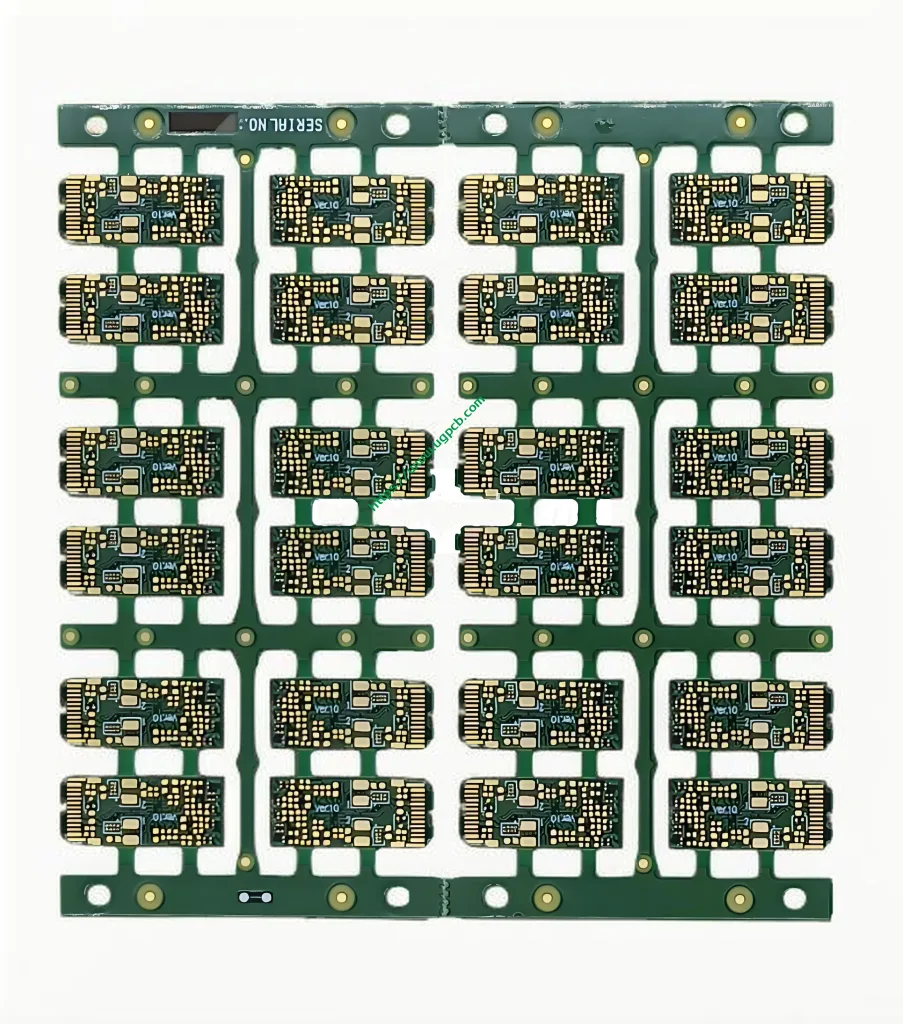

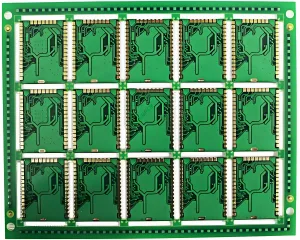

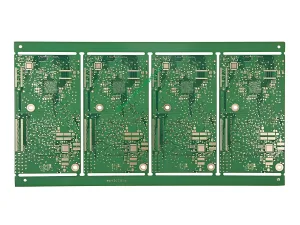

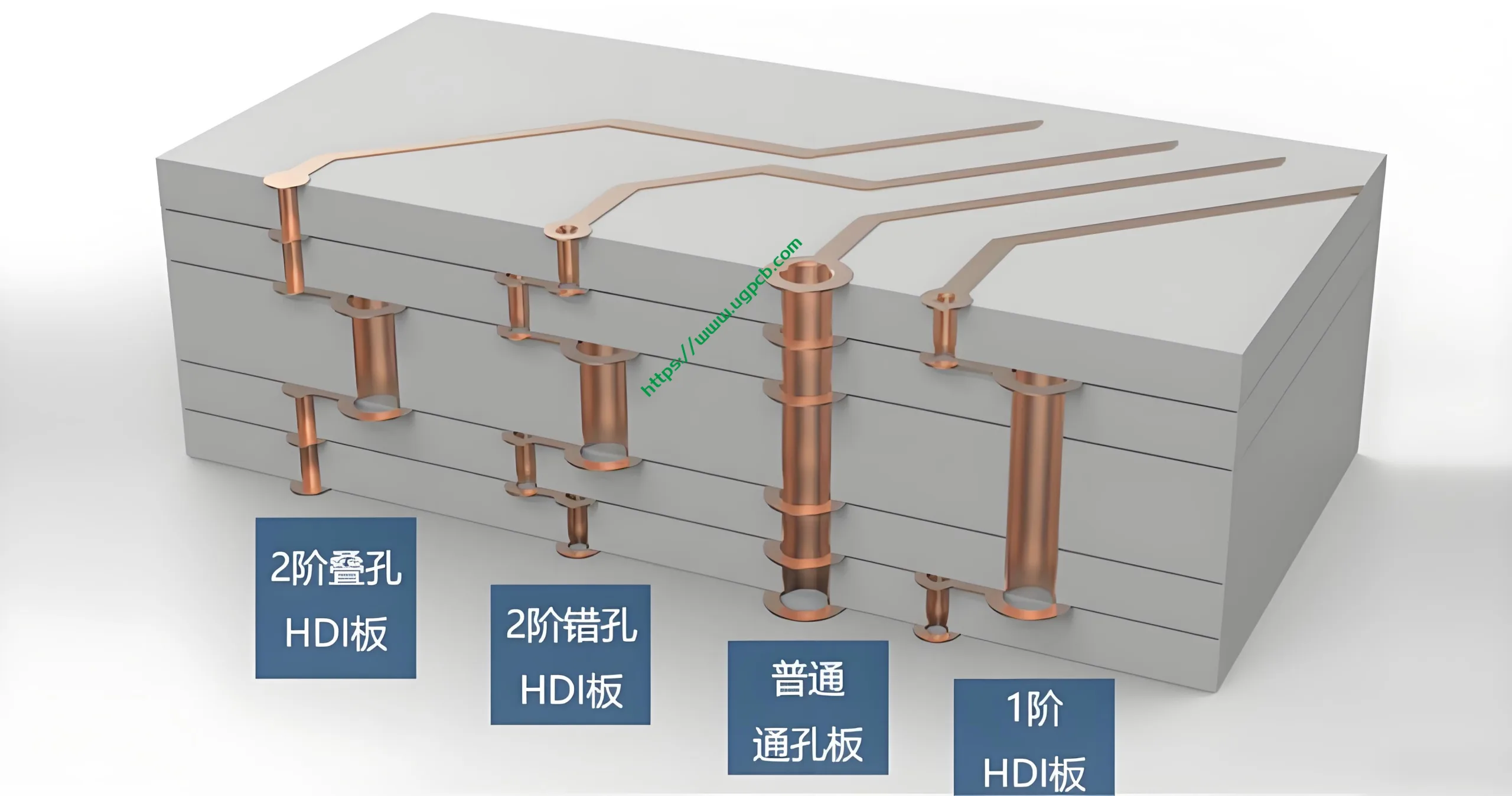

By Layer Count

Multi-layer PCBs, such as the 6-layer HDI (High Density Interconnect) PCB mentioned.

By Material

Constructed from high TG FR4 material for enhanced thermal stability.

By Surface Treatment

Features immersion gold and OSP (Organic Solderability Preservative) surface treatments for improved conductivity and durability.

Materials

The primary materials used in the construction of Type-C Connector PCBs include:

High TG FR4

A flame-retardant glass-reinforced epoxy laminate material known for its high thermal stability and mechanical strength.

نحاس

Used for the conductive traces, with a standard thickness of 1OZ.

Green/White Color (PSR: TAIYO INK)

The color of the PCB, achieved using TAIYO INK for consistent and vibrant results.

Performance

The performance of Type-C Connector PCBs is characterized by:

High Signal Integrity

Ensures minimal loss of signal quality over long distances and high frequencies.

Durability

Resistant to environmental factors such as temperature variations and humidity.

Reliability

Designed to withstand repeated connections and disconnections without degradation.

Structure

The structure of a Type-C Connector PCB typically includes:

Multi-Layer Design

A 6-layer HDI PCB with 2+N+2 layer configuration for complex circuitry.

Fine Pitch Components

Allows for the integration of fine pitch components with a minimum hole size of 0.2mm for mechanical holes and 0.1mm for laser holes.

Advanced Surface Treatments

Immersion gold and OSP coatings enhance conductivity and protect against corrosion.

سمات

Key features of Type-C Connector PCBs include:

High-Speed Data and Power Transmission

Supports USB 3.1 Gen 2 or higher standards for rapid data transfer and up to 100W power delivery.

Compact Design

Slim profile with a finished thickness of 0.8mm, suitable for slim and sleek device designs.

Robust Construction

Made from high TG FR4 material for enhanced durability and thermal stability.

Production Process

The production of Type-C Connector PCBs involves several steps:

Material Preparation

Selection of high TG FR4 material and copper sheets.

Layer Stacking

Stacking of multiple layers to form a multi-layer PCB.

حفر

Creation of holes for through-hole components and vias using mechanical and laser drilling techniques.

Plating

Application of copper plating to create conductive paths.

النقش

Removal of excess copper to form the desired circuit pattern.

المعالجة السطحية

Application of immersion gold and OSP coatings for improved conductivity and protection.

Typical Application Scenarios

Type-C Connector PCBs are widely used in various applications, including:

الالكترونيات الاستهلاكية

الهواتف الذكية, أقراص, أجهزة الكمبيوتر المحمولة, and other portable devices.

Automotive Industry

In-car entertainment systems and charging solutions.

المعدات الصناعية

Control panels and communication devices requiring robust connectivity.

By understanding these aspects, you can appreciate the versatility and importance of Type-C Connector PCBs in modern electronic design.

شعار UGPCB

شعار UGPCB