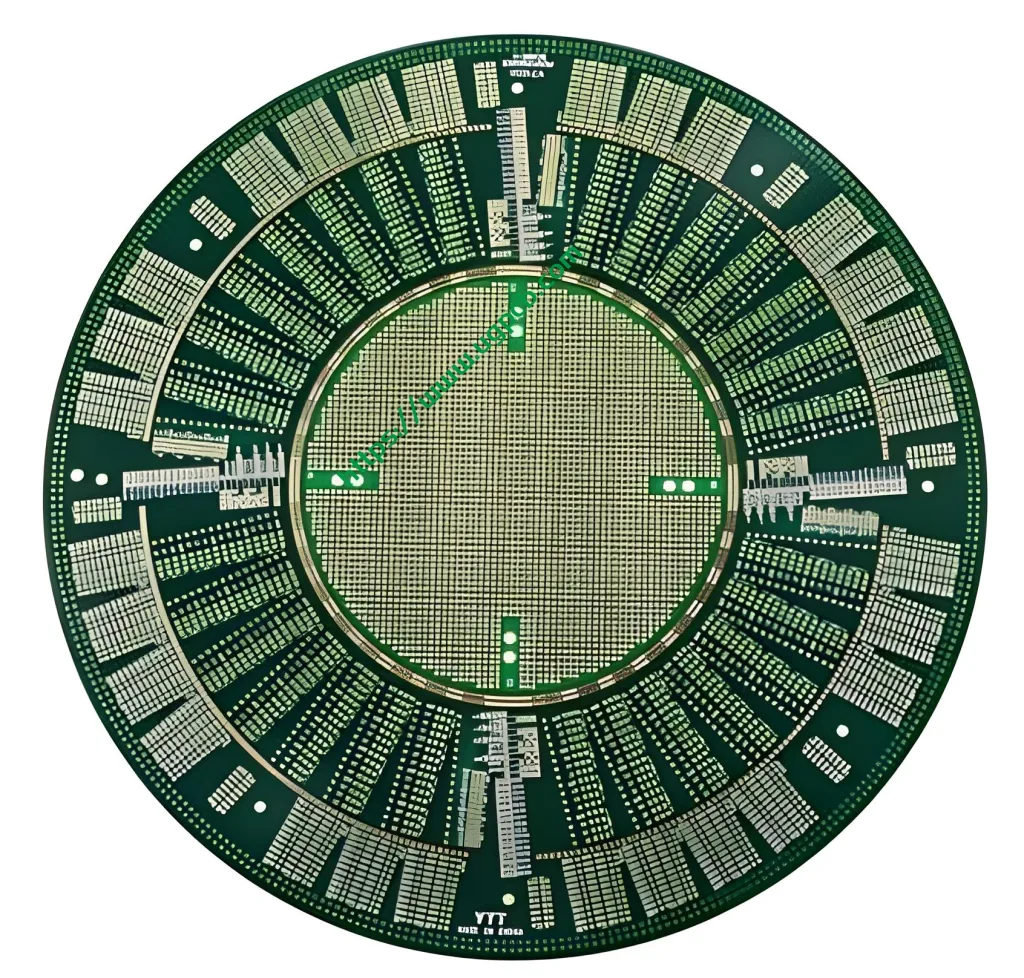

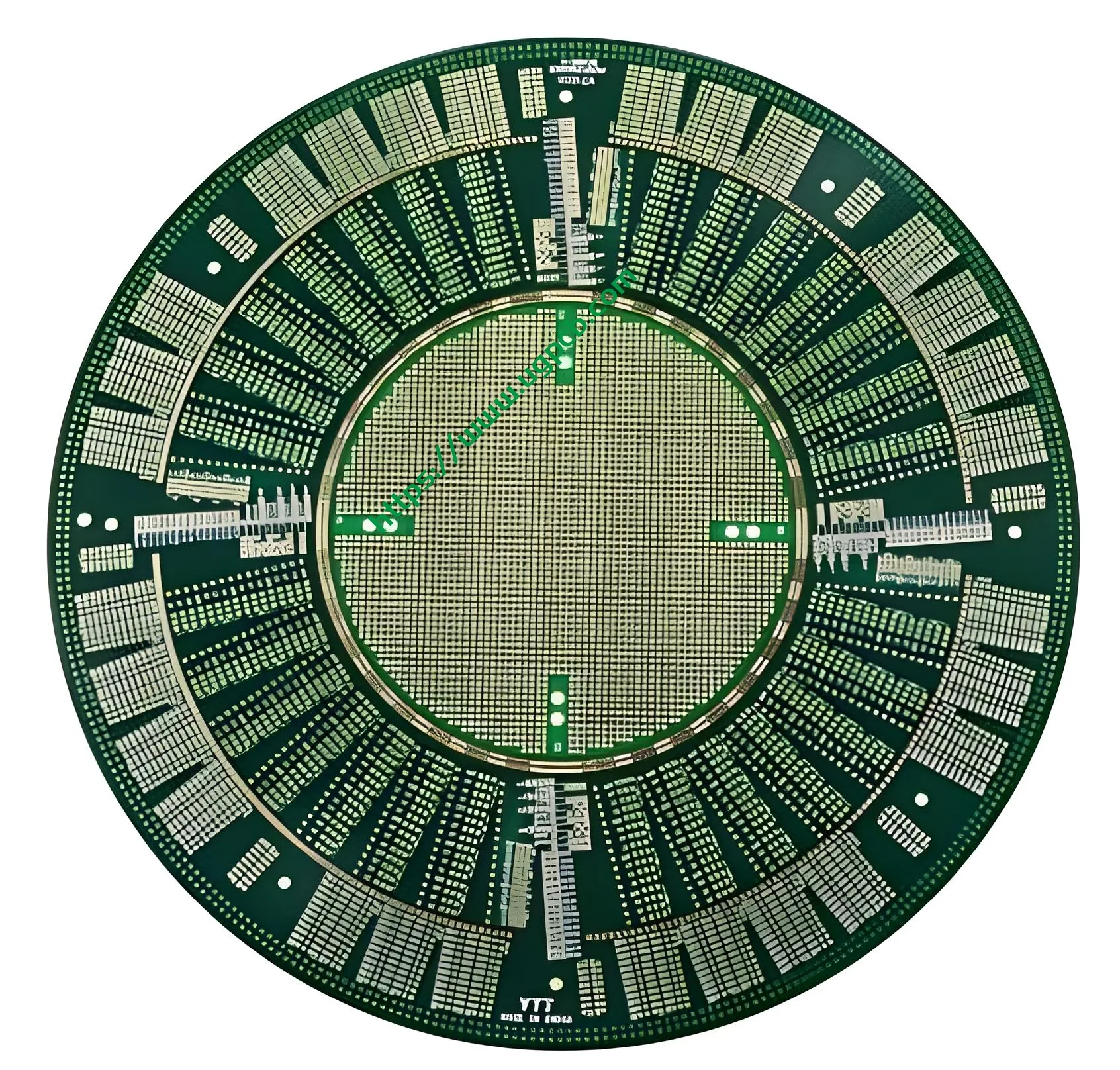

Introduction to IC Chip Test PCB

Overview and Definition

An IC Chip Test PCB, or Integrated Circuit Chip Test Printed Circuit Board, is a specialized circuit board designed for testing integrated circuit chips. It ensures that the chips meet the required specifications before they are used in electronic devices.

مبدأ العمل

The IC Chip Test PCB works by connecting the integrated circuit chip to various test points on the PCB. These test points measure the electrical characteristics of the chip, such as voltage, current, and resistance, to verify its functionality.

Applications

IC Chip Test PCBs are used in the manufacturing and quality control processes of electronic devices. They are essential for ensuring that only functioning and reliable chips are used in the final products.

Types of IC Chip Test PCBs

There are different types of IC Chip Test PCBs based on their design and functionality:

- Functional Test PCBs: Used to test the overall functionality of the chip.

- Parameter Test PCBs: Used to measure specific parameters like power consumption, سرعة, and temperature.

Material and Construction

- مادة: TU872SLS, a high-quality epoxy material.

- طبقات: 20 طبقات, providing robustness and better signal integrity.

- لون: Available in green or white.

- سمك الانتهاء: 2.0مم, ensuring durability while being slim.

- سمك النحاس: 1أوقية, which offers good conductivity.

- المعالجة السطحية: Immersion gold with a thickness of at least 3U”, enhancing corrosion resistance and solderability.

Performance Characteristics

IC Chip Test PCBs are designed to accurately test the performance of integrated circuit chips. They support high-speed data transfer and are built to withstand repeated usage over time. The immersion gold finish ensures long-lasting performance and reliability.

Structural Features

The structure of an IC Chip Test PCB includes multiple layers of copper traces sandwiched between layers of substrate material. This multilayer design helps in managing heat dissipation and improving electrical performance. The PCB is coated with a protective layer to prevent damage and ensure longevity.

Production Process

The production of an IC Chip Test PCB involves several steps:

- Design: Using specialized software to create the circuit layout.

- النقش: Removing excess copper to form the desired patterns.

- Lamination: Combining multiple layers together.

- Plating: Adding a thin layer of metal to improve connectivity.

- Inspection: Ensuring the PCB meets quality standards.

- Assembly: Mounting components onto the PCB.

- Testing: Verifying functionality and performance.

Use Cases

IC Chip Test PCBs are used in various applications including:

- الالكترونيات الاستهلاكية: Mobile phones, أقراص, smartwatches.

- السيارات: In-car systems for navigation and entertainment.

- Medical Devices: Portable medical equipment.

- Industrial Automation: Control systems for machinery and robotics.

In conclusion, IC Chip Test PCBs play a crucial role in the electronics manufacturing process by ensuring the reliability and functionality of integrated circuit chips. Their widespread adoption across different industries highlights their versatility and importance in modern electronic devices.

شعار UGPCB

شعار UGPCB