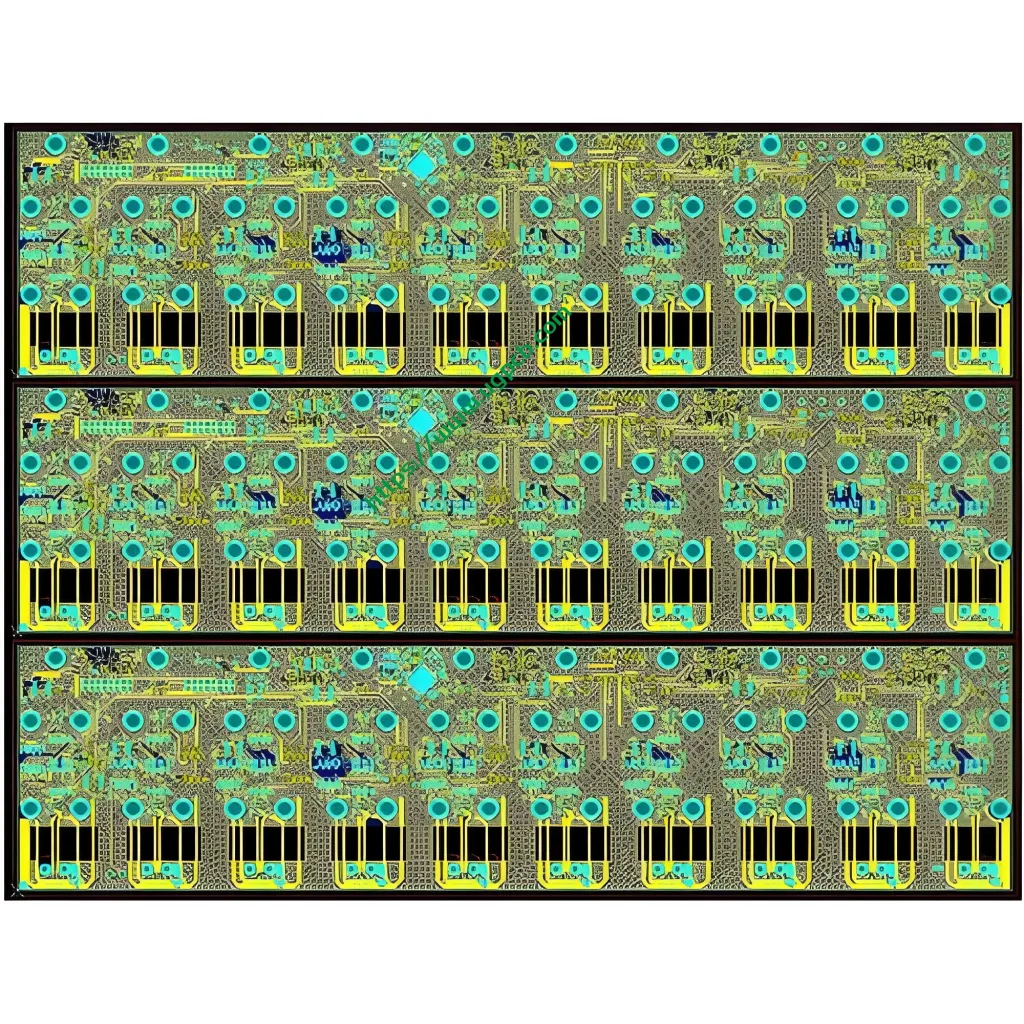

Rigid-Flex PCBs: Key Features and Advantages

Thin Profile and Variable Shapes

One of the key features of rigid-flex PCBs is their thin profile and variable shapes, making them an ideal solution for ultra-thin and ultra-light packaging. Although rigid-flex boards can be more expensive to design and manufacture, they offer many advantages and solve many of the problems associated with traditional rigid board technology.

Small Size and Flexible Shape

Rigid-flex PCBs make it easier to fit more components in a smaller space because they can change shape according to specific contours. This technology reduces the size and weight of the final product as well as the overall system cost. في نفس الوقت, the compact form factor of rigid-flex PCBs makes them the best choice for thin lines and high-density circuits in HDI technology.

Customization for Different Applications

The package geometry freedom of rigid-flex PCBs can be customized for applications in many industries, including aerospace, military, الأجهزة الطبية, and consumer electronics. They can be customized in size and shape to suit housing designs and 3D designs, which gives designers more possibilities to meet different requirements in specific applications.

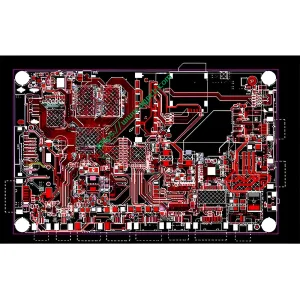

Mechanical Stability and Performance

Better Mechanical Stability

The stability of the rigid board and the flexibility of the flexible board form a stable structure for the entire package, while retaining the reliability and flexibility of electrical connections required for installation in small spaces.

Better Performance in Harsh Environments

Rigid-flex PCBs have high shock and vibration resistance, so they can work well in high-stress environments. Fewer cables and connectors are used in rigid-flex PCBs, which also reduces safety risks and maintenance in future use.

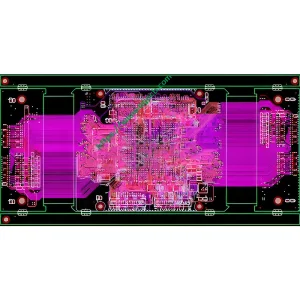

Manufacturing and Testing

Easy to Manufacture and Test

Rigid-flex PCBs require a lower number of interconnects and associated components/parts. This helps simplify assembly operations, making rigid-flex PCBs easier to assemble and test. Rigid-flex PCBs are great for PCB prototyping.

شعار UGPCB

شعار UGPCB