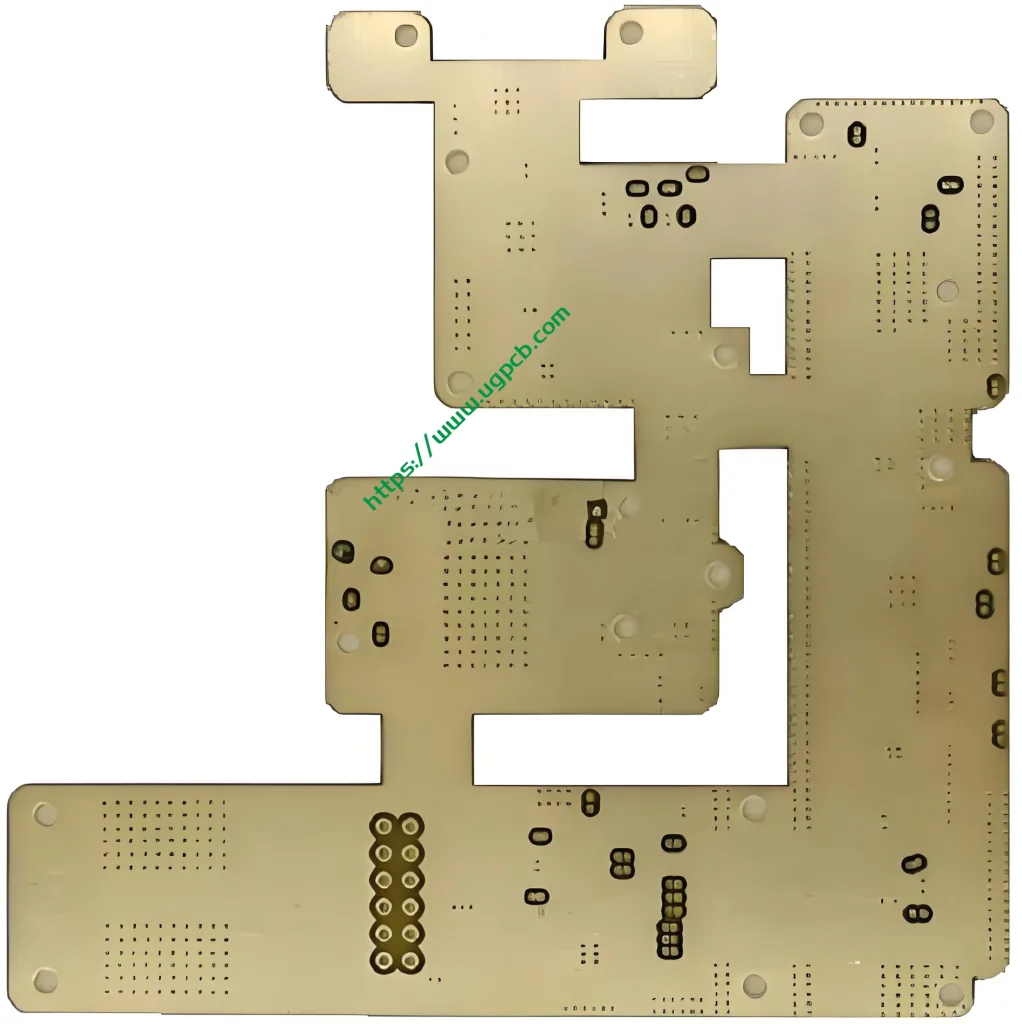

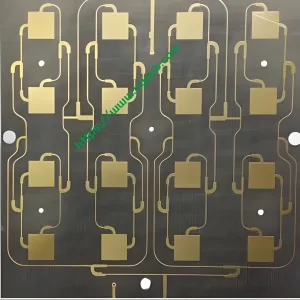

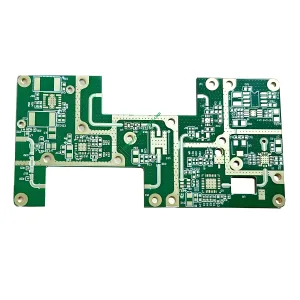

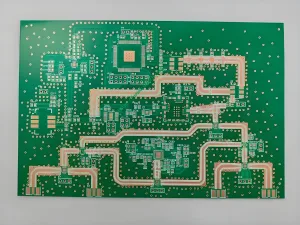

UGPCB Company Specializes in RF PCB Manufacturing

UGPCB company specialized in RF PCB manufacturing for more than 17 سنوات في الصين. We understand the significant impact of the proper RF material on the board’s performance. Parameters like RF microwave energy levels, تردد التشغيل, نطاق درجة حرارة التشغيل, current, and voltage are crucial when selecting suitable material for high-frequency PCB fabricating.

Material Expertise and Stock Assurance

Getting familiar with RF PCB material is one of our jobs. Check below material listing for reference. We have enough of them in stock to ensure fast delivery.

Quality Assurance and Customer Satisfaction

The confidence towards our product quality stems from our experienced engineers and production team, who cooperate closely with our QA department to provide a qualified product. More and more repeat orders speak to our customers’ satisfaction. الجودة هي القيمة الأساسية لشركتنا, and we recognize its importance for long-term business. We are grateful to our customers for accompanying us in developing and improving our capacity and technical field over the past 17 سنين.

List of RF/Microwave PCB Materials

RF/Microwave PCB materials include Rogers RO4350B / 3003 ريال عماني / RO4003 / RO3006 / RT / duroid 5880 / RT5870, and others like Arlon, العازلة, تاكونيك, PTFE F4BM, and Teflon material.

Hybrid PCB Materials

Hybrid PCB materials (مختلطة العزل الكهربائي / صفح) include Rogers RO4350B + FR4, 4350 مليار ريال عماني + IT180, RO4003C + FR4, 3010 ريال عماني + FR4, 3003 ريال عماني + FR4, and others.

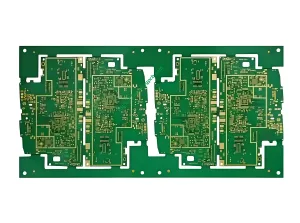

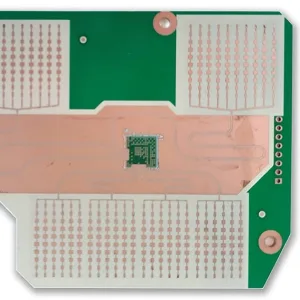

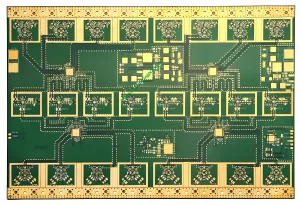

RF Microwave PCB Applications and Specifications

RF Microwave PCBs are used in various fields such as Consumer Electronics, العسكرية/الفضاء, قوة عالية, طبي, السيارات, and Industrial. Specifications include surface finishing options like OSP, يوافق, HASL LF, plated gold, فلاش الذهب, immersion tin, immersion silver, electrolytic gold, and others. Capacity includes golden finger, heavy copper, blind/buried via, التحكم في المعاوقة, filled with resin, حبر الكربون, خلفية, عدادات, حفر العمق, نصف ثقب مطلي, ثقب PressFit, قناع الأزرق القابل للتقشير, جندي قابلة للتقشير, النحاس الكثيف, and oversize. Materials include Rogers RO4350B, 3003 ريال عماني, RO4003, RO3006, RT / duroid 5880, RT5870, آرلون, العازلة, تاكونيك, PTFE F4BM, and Teflon. Layers range from 2L to 30L. ثابت العزل الكهربائي (DK) values include 2.20, 2.55, 3.00, 3.38, 3.48, 3.50, 3.6, 6.15, و 10.2. Applications include Consumer Electronics, العسكرية/الفضاء, هوائي & نظام الاتصالات, قوة عالية, طبي, السيارات, صناعي, الجهاز باليد الخلوية, هوائي wifi, عن بعد والترفيه, Wifi/Computing/Radar/Power.

Material Model Corresponding to RO4003C PCB

Material models corresponding to RO4003C PCB include RO4450F, 4450B BOND PLY 14X24 UNPUNCHED SHEET, 4450B BOND PLY 24X20 UNPUNCHED SHEET, and various others. Note that RO4003C is not UL certified.

Copper Foil Manufacturing Changes Due to EU and REACH Regulations

Copper foil manufacturers are eliminating the use of arsenic acid in their manufacturing processes under EU and REACH regulations. This legislation made it difficult to use arsenic compounds in the manufacture of copper foil and ultimately banned the purchase of arsenic completely in the European Union. The Rogers RO4003C PCB material is affected by this, and the standard electrodeposited copper foil used for RO4003C PCB material will be replaced by a new grade of copper foil that complies with EU regulations during 2020.

شعار UGPCB

شعار UGPCB