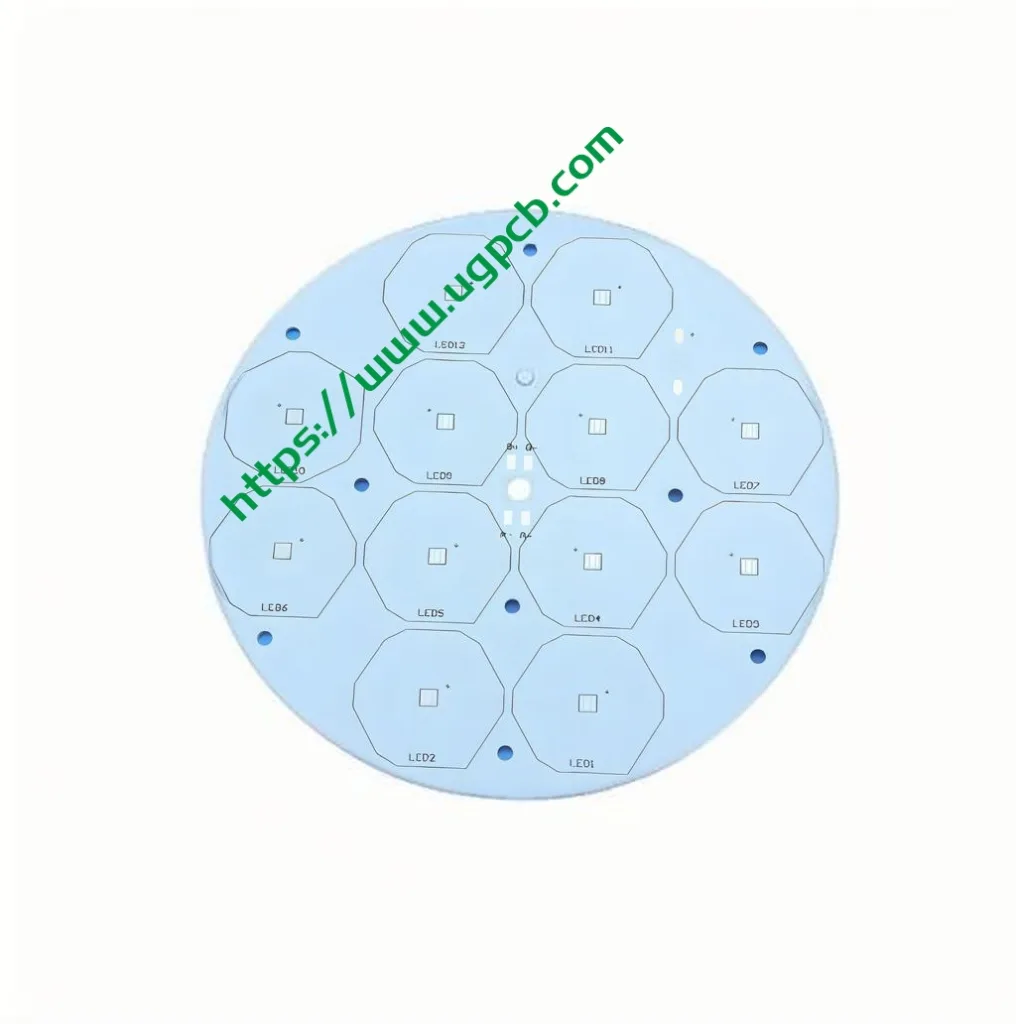

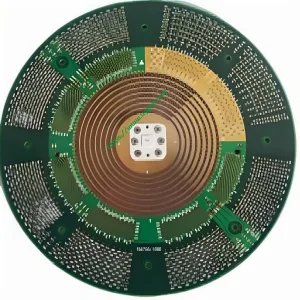

Material Composition

The Single Side Aluminum Based PCB is crafted from a robust aluminum base, offering exceptional thermal conductivity and mechanical stability. Aluminum is chosen for its lightweight properties, corrosion resistance, and cost-effectiveness, making it an ideal material for LED board applications.

Performance and Characteristics

- Layer Structure: The PCB features a single-layer design, simplifying manufacturing processes and reducing costs while maintaining efficient electrical performance.

- Color Options: Available in white or black, the PCB can seamlessly integrate into various LED lighting designs, enhancing aesthetic appeal.

- سمك الانتهاء: With a thickness of 1.2mm, the PCB provides a sturdy foundation for mounting LED components, ensuring reliable performance and durability.

- سمك النحاس: The copper thickness of 2OZ ensures high electrical conductivity and current carrying capacity, critical for LED lighting applications that require bright and consistent illumination.

- المعالجة السطحية: The PCB undergoes Organic Solderability Preservatives (OSP) treatment, providing a protective layer that enhances solderability and protects against corrosion, ensuring long-term reliability.

- Thermal Conductivity: The PCB boasts a thermal conductivity of 1.0w/m.k, effectively managing heat generated by LED components, thus preventing overheating and prolonging the lifespan of the LED board.

Unique Features

- Enhanced Thermal Management: The aluminum base’s high thermal conductivity allows for efficient heat dissipation, ensuring optimal LED performance and preventing premature failure.

- Cost-Effective Solution: The single-layer design and aluminum material reduce manufacturing costs, making the PCB an economical choice for LED lighting applications.

- Aesthetic Flexibility: The availability of white and black color options allows for greater design flexibility, enabling the PCB to blend seamlessly into various lighting designs.

Production Process

The production of the Single Side Aluminum Based PCB involves several key steps:

- Material Preparation: High-quality aluminum sheets are selected and prepared for PCB manufacturing.

- Circuit Patterning: Using photolithography and etching techniques, the desired circuit patterns are etched onto the copper layer adhered to the aluminum base.

- Copper Plating: Additional copper is plated onto the etched circuit patterns to achieve the desired thickness of 2OZ, ensuring high electrical conductivity.

- Surface Finishing: The PCB undergoes OSP treatment to enhance solderability and corrosion resistance.

- ضبط الجودة: Rigorous testing and quality control measures are implemented to ensure the PCB meets all specifications and standards for LED lighting applications.

Application Scenarios

The Single Side Aluminum Based PCB is designed for use in a variety of LED lighting applications, including:

- LED Strip Lights: The PCB’s lightweight and durable design makes it ideal for use in flexible LED strip lights, providing bright and consistent illumination for indoor and outdoor lighting solutions.

- LED Downlights: The PCB’s efficient thermal management capabilities ensure reliable performance of LED downlights, making them suitable for use in commercial and residential lighting systems.

- LED Signage: The PCB’s cost-effectiveness and aesthetic flexibility make it an excellent choice for use in LED signage, enabling vibrant and eye-catching displays for businesses and events.

شعار UGPCB

شعار UGPCB