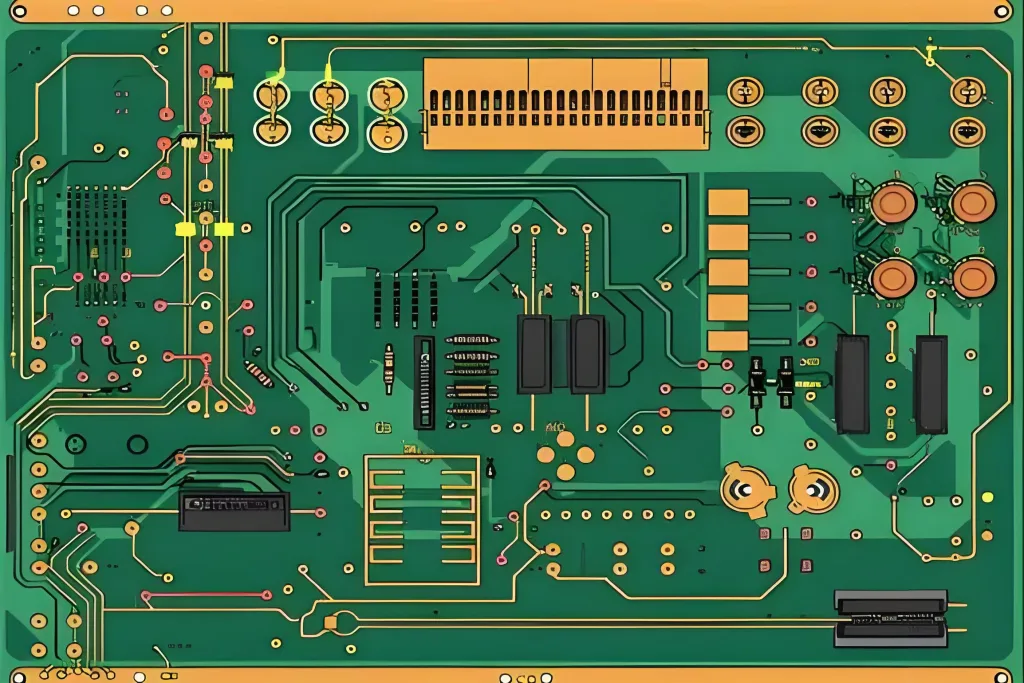

Teflon PCB in high-end electronic products uses Teflon laminate material. The scientific name of Teflon is polytetrafluoroethylene (PTFE). This material is resistant to acids, alkalis, and various organic solvents, and is almost insoluble in all solvents. في نفس الوقت, Teflon material has the characteristics of high-temperature resistance, and its dielectric coefficient is very low, so it is an ideal high-frequency PCB material for high-frequency Teflon PCB.

Teflon PCB has a series of excellent performances:

High-temperature resistance: long-term use temperature 200~260 degrees;

Low-temperature resistance: still soft at -100 degrees;

Corrosion resistance: can withstand aqua regia and all organic solvents;

Weather resistance: the best aging life among plastics;

High lubrication: has the smallest coefficient of friction in plastics (0.04);

Non-sticky: It has the smallest surface tension among solid materials without adhering to any substance;

It is physiologically inert; it has excellent electrical properties and is an ideal C-level insulating material. A thick layer of newspaper can block the high voltage of 1500V; it is smoother than ice.

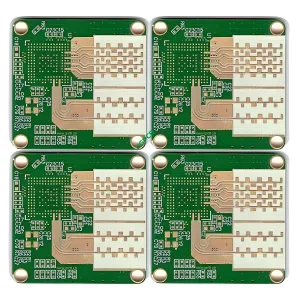

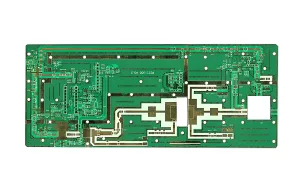

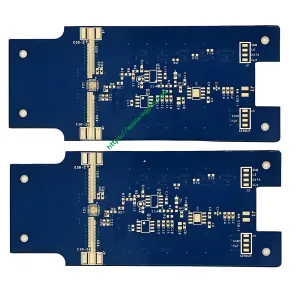

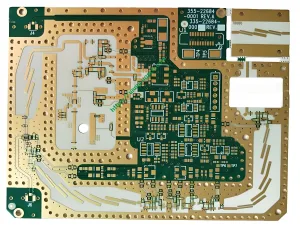

Teflon has outstanding excellent comprehensive properties, high-temperature resistance, corrosion resistance, non-stick, self-lubricating, excellent dielectric properties, and a very low coefficient of friction. Among Teflon PCB, Teflon is a high-frequency PCB material with very excellent performance, which is very suitable for applications in radar, high-frequency communication equipment, radio equipment, وغيرها من المجالات. عادة, in Teflon PCB, general manufacturers seldom use this kind of Teflon sheet, UGPCB can provide Teflon PCB to meet customers’ various PCB needs. في الوقت الحالي, in the manufacture of Teflon PCB for UGPCB, Teflon PCB material can achieve 4~6 layers of pure compression; 4~8 layers of mixed compression.

The characteristics of Teflon PCB board mainly include the following categories:

1. Income

Both the Teflon PCB and the low-frequency power supply circuit have the effect of voltage gain and output power harvesting. Resonant differential amplifier circuit, it refers to the resonant frequency F0, for fiber broadband differential amplifier circuit, it refers to a frequency region.

2. Passband

The concept of low-frequency power supply PCB is not bad. For resonant differential amplifier circuits, most of the pointers refer to the value between the two corresponding frequencies when the normalized vibration amplitude of the resonant frequency f0 drops to 0.707; for fiber optic broadband amplifier circuits, it refers to It means corresponding to a certain frequency.

3. Selectivity

The selectivity is mainly for the resonant amplifier circuit, which characterizes the circuit’s selection of useful signals and its ability to suppress unwanted signals. It is usually measured by rectangular coefficient and suppression ratio based on the circuit’s resonance characteristic curve.

4. Noise figure

When the amplifying circuit is working, due to some factors, the fluctuations will move irregularly, forming noise inside the circuit, which will affect the quality of the signal. This effect is usually described by the ratio of signal power PS to noise power PN (SNR). The noise coefficient is the comparison between input signal noise and output signal noise.

5. Stability

The stability of high-frequency Teflon PCB refers to the stability of its main performance when the working state or working conditions are changed. على سبيل المثال, when the temperature of the environment changes or the voltage of the power supply fluctuates, it will affect the normal state of the DC operation of the amplifier circuit; the parameters of the circuit components will also change accordingly, which will cause the gain of the amplifier circuit to change, The frequency shift of the center and the curve of resonance suddenly change greatly. In the end, it may not work at all.

Brief description: High-frequency Teflon PCB is mainly: high income, high receiving signal, wide range, low noise figure, and high stability.

أولاً, the definition of high-frequency Teflon PCB.

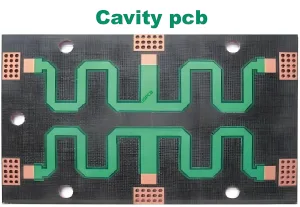

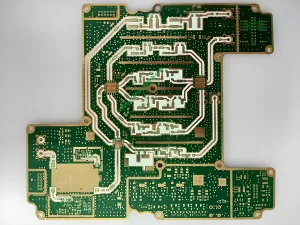

High-frequency Teflon PCB refers to PCBs with higher electromagnetic frequencies used in high-frequency (frequency higher than 300MHz or band length not higher than 1m) and microwave (frequency higher than 3GHz or wavelength not higher than 0.1m). It is a PCB produced on microwave Teflon copper-clad laminates using ordinary rigid circuit board manufacturing methods or special processing methods. بشكل عام, high-frequency Teflon PCB can be regarded as a PCB with a frequency above 1GHz.

With the rapid development of science and technology, many types of equipment are planned in the microwave frequency band (>1GHz) or even millimeter wave (30ghz) range. It can be seen that the frequency is getting higher and higher, and the requirements for the Teflon PCB board are also higher. على سبيل المثال, the base material needs to have high-quality electrical properties and chemical stability. As the frequency of the power signal increases, the loss of the sheet is very small, and the importance of high-frequency Teflon PCB is becoming increasingly prominent.

Second, the scope of application of high-frequency Teflon PCB

2.1 Related to lighting and communication systems

2.2 Power amplifier, low noise amplifier, إلخ.

2.3 Passive components such as power splitters, couplers, duplexers, filters, إلخ.

2.4 In the fields of automobile anti-collision systems, أنظمة الأقمار الصناعية, and radio systems, high-frequency electronic equipment is a development trend.

UGPCB is a Teflon PCB manufacturing factory. UGPCB provides a variety of well-known brands of Teflon PCB, such as Rogers Teflon PCB, Taconic Teflon PCB, and has prepared sufficient Teflon PCB board to meet your rapid needs.

Wangling’s products include Teflon fiberglass cloth copper clad laminate, ceramic filled Teflon fiberglass cloth copper-clad laminate series, microwave composite dielectric substrate series, microwave multilayer Teflon PCB, microwave electronic devices and insulation, Anti-stick varnished cloth.

Teflon PCB products are widely used in aerospace, الطيران, satellite communications, navigation, الفضاء الجوي, radar, electronic countermeasures, 3ز, 4ز, 5G communications, Beidou satellite systems, وغيرها من المجالات. In particular, the F4B series Teflon PCB laminate can meet the needs of multiple industries, and the price is much cheaper, which has great advantages and is a very good choice for Teflon PCB. UGPCB has many years of experience in processing Teflon PCB products. It can process Teflon PCB, Teflon + FR4 multilayer hybrid PCB. The products produced are used in various industries and have achieved a good reputation. Especially 5G communications, RF radio frequency products.

شعار UGPCB

شعار UGPCB