Leiterplatte: The Foundation of the Electronic World

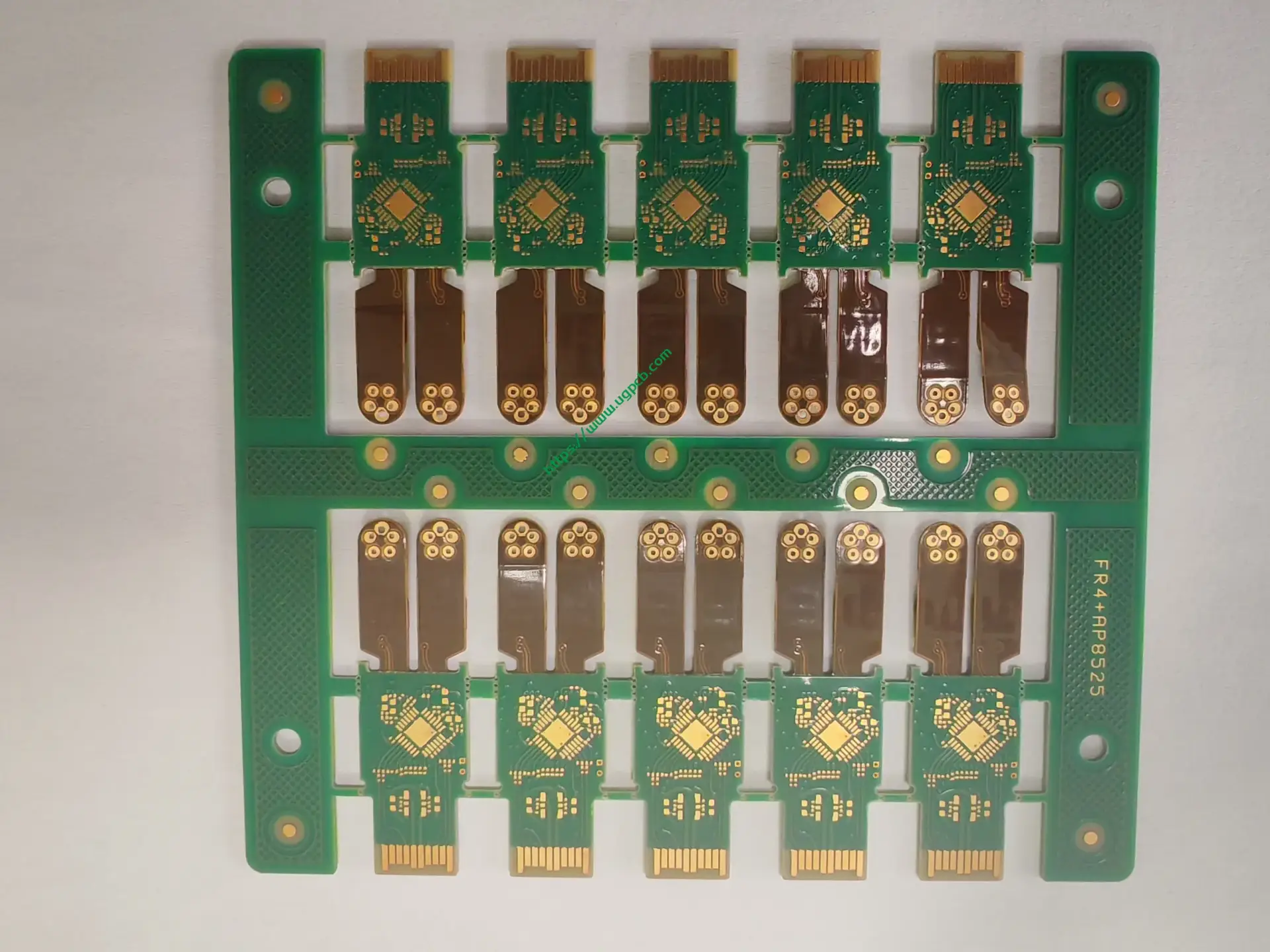

Leiterplatte, Abkürzung für „Printed Circuit Board“., ist einer der Kernbestandteile elektronischer Geräte. Als verbindender Träger elektronischer Bauteile, Es wird durch elektronische Drucktechnologie hergestellt, hence the name “printed circuit board.” PCB substrates are made of various materials, including phenolic resin, fiberglass, Teflon plastic, ceramic, Kupfer, and aluminum, which are chosen based on their insulating properties and mechanical strength.

Leiterplatte: The Glorious Transformation of PCB

Leiterplatte, short for Printed Circuit Board Assembly, is the finished product formed by assembling PCB bare boards with various electronic components such as ICs, Kondensatoren, Widerstände, und Anschlüsse. On a PCB bare board, electronic components are first mounted through SMT (Oberflächenmontagetechnologie), and then pins are inserted into the holes on the board through DIP (Dual-Inline-Paket). Endlich, after soldering and testing, a finished electronic product is created for users.

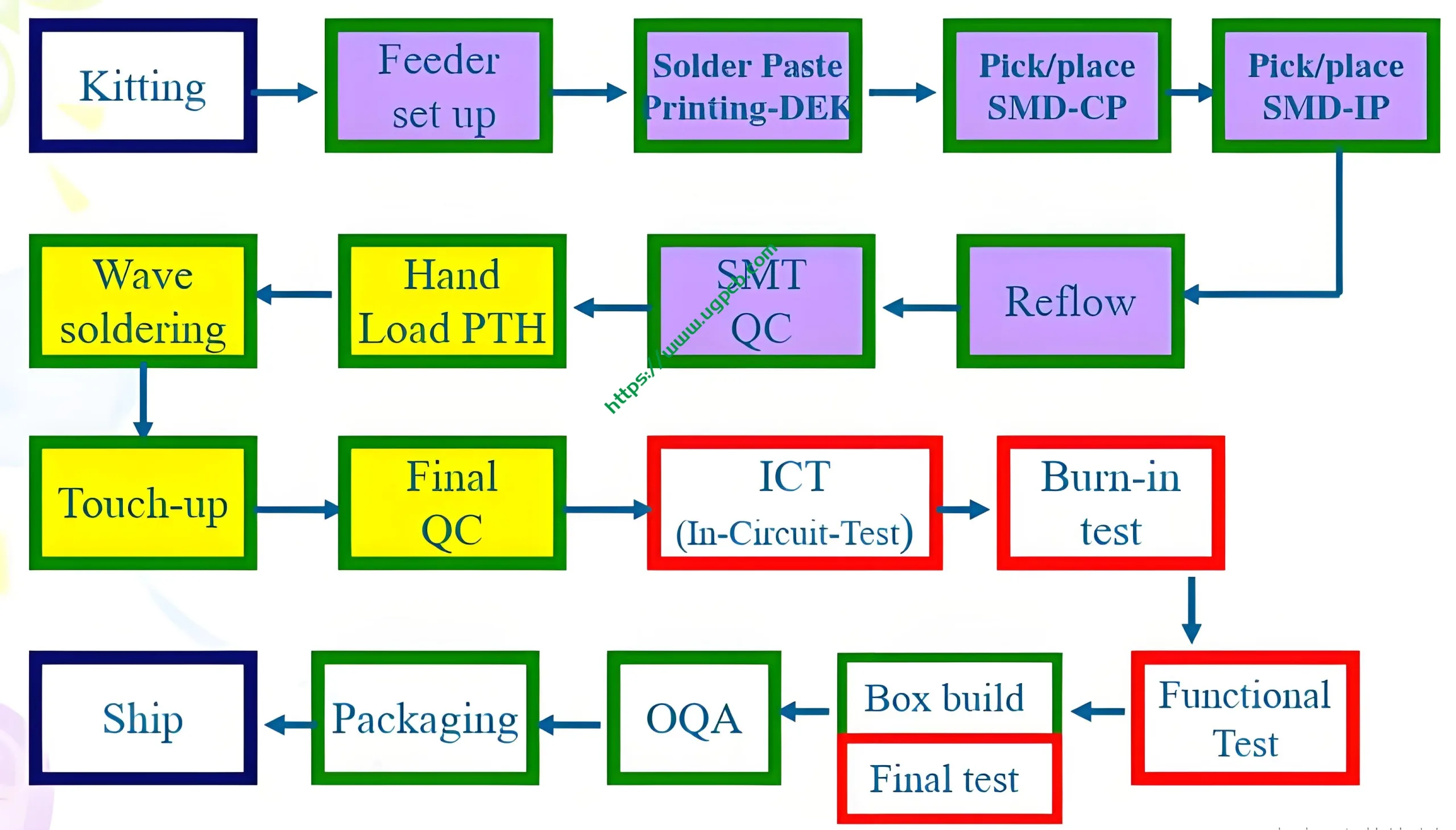

The PCBA Manufacturing Process: From Bare Board to Finished Product

The PCBA manufacturing process includes SMT processing and DIP processing, with the following specific steps:

-

Board Loading: Place the PCB bare board on the production line for subsequent operations.

-

Printing: Print solder paste on the soldering pads of the PCB to prepare for mounting electronic components.

-

Component Mounting: Use automated equipment or manual labor to mount electronic components onto the soldering pads of the PCB.

-

Reflow-Löten: Place the mounted PCB into a reflow soldering oven, where high temperatures melt the solder paste to weld the electronic components onto the PCB.

-

Component Insertion: For components that need to be installed through DIP, insert their pins into the holes on the PCB.

-

Wave Soldering: Place the inserted PCB into a wave soldering machine, where a molten wave of solder welds the pins to the PCB.

-

Testing and Quality Inspection: Conduct functional and appearance tests on the soldered PCBA to ensure product quality.

Depending on production technology and requirements, there are various PCBA process flows, such as single-sided mixed assembly, single-sided DIP insertion, single-sided SMT mounting, single-sided mounting and double-sided mixed assembly, double-sided SMT mounting, and mixed insertion processes.

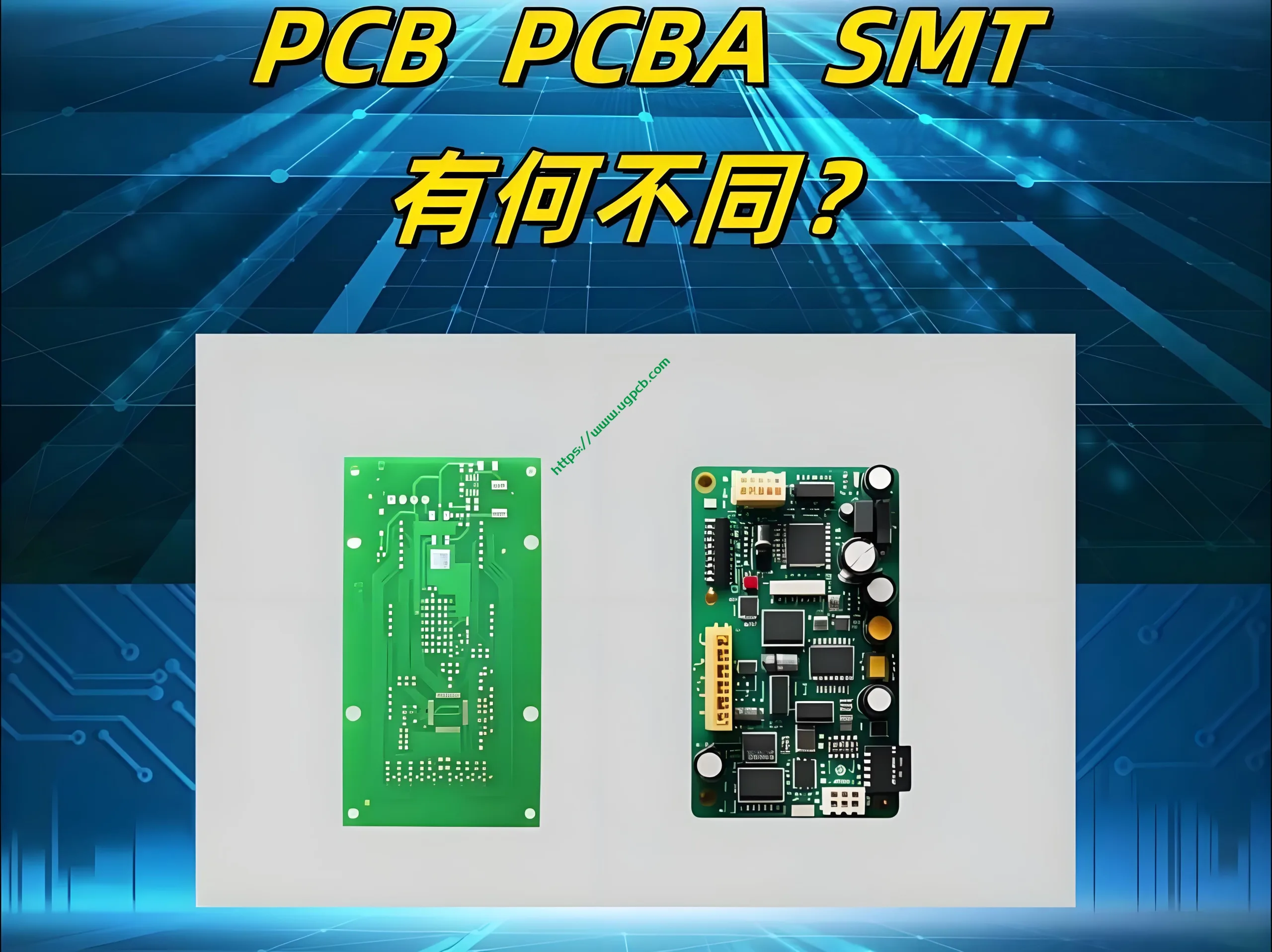

The Difference Between PCB and PCBA: From Bare Board to Finished Product

PCB is a bare board without electronic components, while PCBA is a finished product that includes electronic components. Simply put, PCB is the “predecessor” of PCBA, and PCBA is the “finished product” formed after a series of processing and assembly steps on a PCB.

UGPCB: One-Stop PCB,PCBA and PEVCD Service Expert

UGPCB has years of experience in PCBA manufacturing and is dedicated to providing customers with quality one-stop PCB,PCBA and PEVCD services. We understand the importance of every production step, so from raw material procurement to production processing and quality inspection, we strictly control every aspect to ensure that every PCBA meets customer requirements and expectations.

UGPCB-LOGO

UGPCB-LOGO