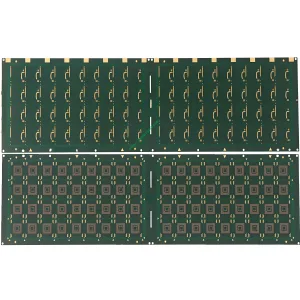

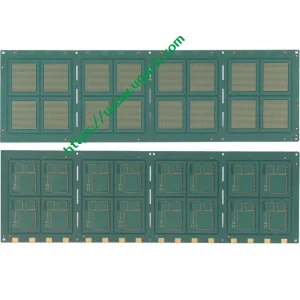

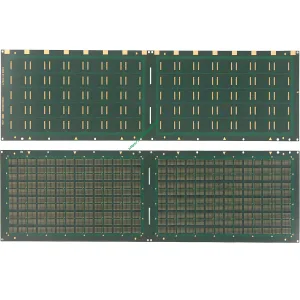

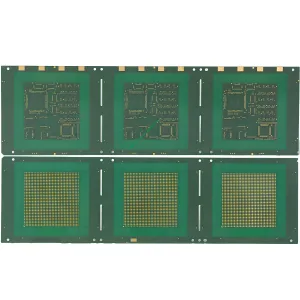

IC-Substrat

IC Substrates: Key Components in Modern Electronics

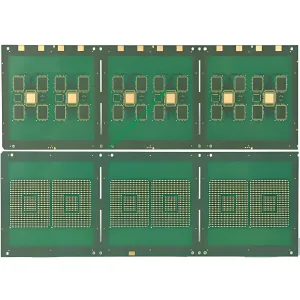

Ein IC-Substrat (integrated circuit substrate) serves as an indispensable platform in electronic devices, supporting and interconnecting IC chips and components. With industries like aerospace, Maschinen, and chemical engineering advancing toward multifunctionality and miniaturization, technical requirements for IC substrates have become increasingly rigorous.

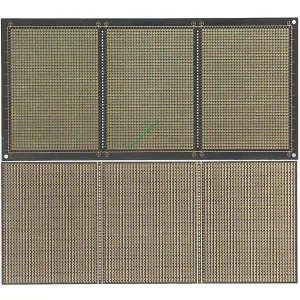

Core Functions of IC Substrates

- Component Interconnection: Metal conductors on the substrate enable electrical connections between components, Erleichterung der Stromübertragung und Signalübertragung.

- Physical Support & Protection: Provides structural stability, ensures proper component alignment, and reduces electromagnetic interference (EMI) and signal crosstalk.

- Thermal Management: Offers heat dissipation and insulation to enhance product reliability and performance.

IC Substrate Classifications

By Material:

- Rigid Packaging Substrates (most widely used)

- Flexible Packaging Substrates

- Ceramic Packaging Substrates

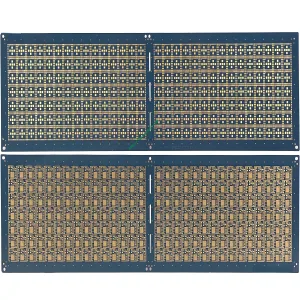

By Application:

- Memory chip packaging

- Logic chip packaging

- Sensor chip packaging

- Communication chip packaging

Technical Significance in IC Packaging

IC substrates act as critical bridges between chips and conventional PCBs, ensuring:

- Electrical signal transition and compatibility

- Mechanical protection and standardized mounting dimensions

- Efficient heat dissipation channels

Continuous advancements in packaging technology drive innovations in substrate design and manufacturing to meet demands for high performance, Zuverlässigkeit, and miniaturization.

Zukünftige Aussichten

As a cornerstone of electronics, IC substrate technology will evolve with emerging demands, propelling progress across industries through material innovations, precision manufacturing, and thermal optimization.

UGPCB-LOGO

UGPCB-LOGO

WeChat

Scannen Sie den QR-Code mit WeChat