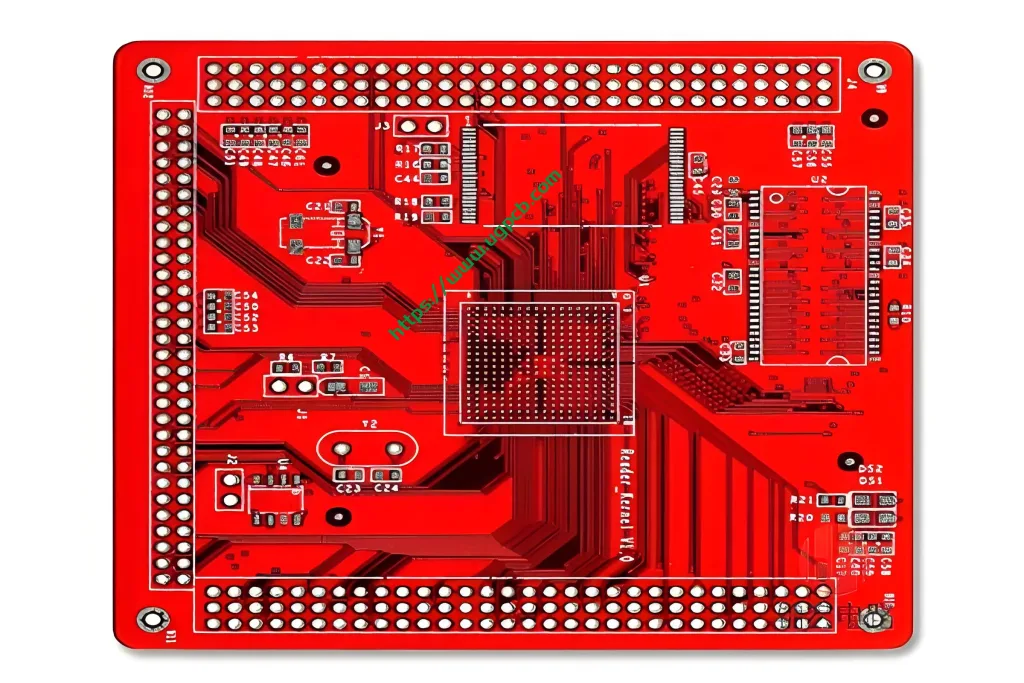

Introduction to 10L Blind & Buried Hole PCB

The 10L Blind & Buried Hole PCB is a high-density interconnect (HDI) printed circuit board designed for complex electronic applications. This PCB features blind and buried hole technologies, which allow for intricate internal connections without compromising surface real estate. It is suitable for demanding applications requiring advanced functionality and reliability.

Zweck und Anwendungen

Digital PCB

Primarily used in digital circuits, the 10L Blind & Buried Hole PCB ensures reliable connectivity and data transmission in critical electronic setups. Sein robustes Design macht es ideal für Anwendungen, die eine hohe Signalintegrität und Haltbarkeit erfordern.

Klassifizierung und Materialien

FR4 Material

Constructed from FR4, Diese PCB bietet eine hervorragende thermische Stabilität und mechanische Stärke. Die 1oz Kupferdicke verbessert die Leitfähigkeit und die Wärmeabteilung, Damit es für Hochleistungsanwendungen geeignet ist.

Leistung und Spezifikationen

Schichtstruktur und spezielle Prozesse

Die PCB besteht aus 10 Schichten mit einer einzigartigen Schichtstruktur: [specific layer structure details if provided]. It incorporates blind and buried holes, die komplexe interne Verbindungen ermöglichen, ohne die Oberflächenimmobilien des Boards zu beeinträchtigen. Die minimale Lochgröße beträgt 0,2 mm (8Mil), Voraussetzungen für Feinkopienkomponenten.

Oberflächenbehandlung und Spur/Raum

The surface treatment is immersion gold, Bereitstellung einer guten Lötlichkeit und Korrosionsbeständigkeit. The trace/space configuration is 2.5mil/2.5mil, Gewährleistung eines präzisen und dichten Schaltungslayouts.

Produktionsprozess

Schritte bei der Herstellung

- Materialvorbereitung: FR4 boards are cut to the required dimensions.

- Schichtstapel: Die Schichten sind gemäß der angegebenen Struktur gestapelt.

- Bohren: Blind and buried holes are drilled with precision.

- Überzug: Die Löcher werden plattiert, um elektrische Verbindungen zwischen Schichten herzustellen.

- Radierung: Unnötiges Kupfer wird entfernt, um das gewünschte Schaltungsmuster zu bilden.

- Oberflächenbehandlung: The board undergoes immersion gold treatment for enhanced solderability.

- Inspektion: Jeder Vorstand wird gründlich inspiziert, um Qualität und Einhaltung der Spezifikationen zu gewährleisten.

Schlüsselmerkmale und Vorteile

Fortgeschrittene Technologieintegration

The integration of blind and buried holes allows for more complex and compact designs, Reduzierung der Gesamtgröße der PCB und bei der Aufrechterhaltung einer hohen Funktionalität.

Hohe Zuverlässigkeit und Haltbarkeit

The use of FR4 material ensures that the PCB can withstand high temperatures and harsh conditions, es für den langfristigen Gebrauch zuverlässig machen.

Verbesserte Signalintegrität

Die 1oz -Kupferdicke und die präzise Spur-/Raumkonfiguration tragen zur überlegenen Signalintegrität bei, crucial for digital applications where data accuracy is paramount.

Anwendungsfälle und Szenarien

Digital Circuits

In digital circuits, the 10L Blind & Buried Hole PCB provides a stable platform for various electronic components, Gewährleistung des nahtlosen Betriebs und Datenschutzes.

Industrieautomatisierung

Für industrielle Automatisierung, this PCB supports high-speed data transfer and robust connectivity essential for controlling machinery and monitoring processes efficiently.

Luft- und Raumfahrt und Verteidigung

In Luft- und Raumfahrt- und Verteidigungsanwendungen, Die hohe thermische Stabilität und Zuverlässigkeit der PCB machen es für missionskritische Geräte und Systeme geeignet.

Abschluss

The 10L Blind & Buried Hole PCB stands out as a high-performance solution for complex electronic applications, especially in digital circuits. Seine fortgeschrittenen Funktionen, robuste Materialien, und präziser Herstellungsprozess gewährleisten die Zuverlässigkeit und Effizienz in anspruchsvollen Umgebungen.

UGPCB-LOGO

UGPCB-LOGO