Materialzusammensetzung

The Aluminum Nitride Ceramic PCB is composed of high-quality ceramic materials, specifically ceramic PCB and ceramic substrate. This combination ensures exceptional thermal conductivity and electrical insulation properties.

Leistungseigenschaften

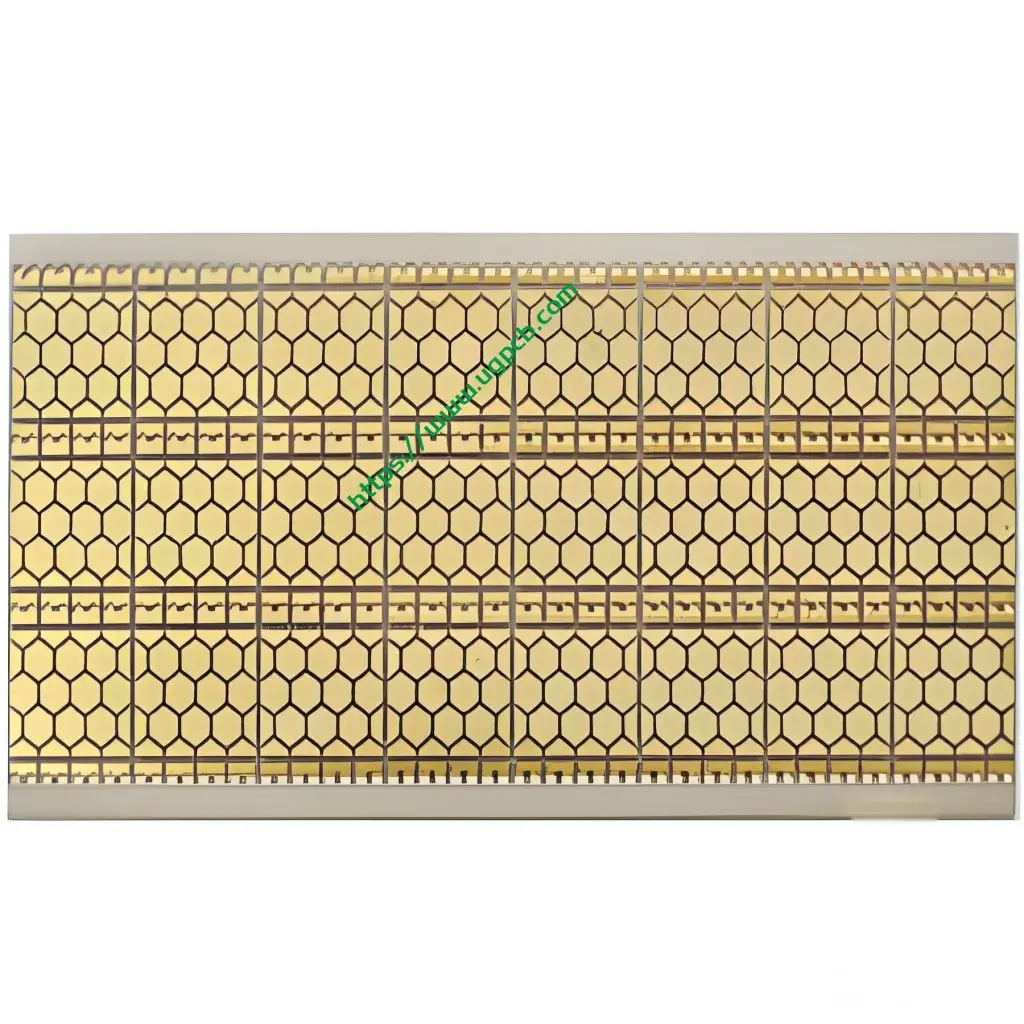

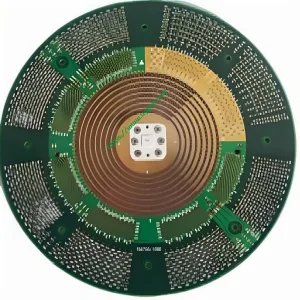

The PCB features a 2-layer ceramic structure with a white color appearance. The thickness of the aluminum nitride layer is precisely 0.635mm, providing a sturdy base for components. The copper thickness of 1OZ (35eins) ensures good electrical conductivity, while the immersion gold surface treatment with a gold thickness of >= 3U” enhances corrosion resistance and ensures smooth soldering processes.

Distinctive Features

- Hohe thermische Leitfähigkeit: Aluminum nitride offers excellent thermal conductivity, making it suitable for high-power and high-frequency applications.

- Durability: Ceramic materials are known for their hardness and durability, contributing to the PCB’s long lifespan.

- Precision: The minimum aperture of 0.8mm allows for the placement of fine components, ensuring high-density packaging.

Produktionsprozess

The production of Aluminum Nitride Ceramic PCBs involves several critical steps:

- Materialvorbereitung: High-quality aluminum nitride powder and other ceramic materials are mixed and pressed into the desired shape.

- Sintering: The pressed ceramic substrate undergoes sintering at high temperatures to achieve the required density and strength.

- Copper Deposition: A layer of copper is deposited on the ceramic substrate using advanced metallization techniques.

- Circuit Patterning: The copper layer is etched to form the desired circuit patterns.

- Hole Drilling: Through holes are drilled to allow for interconnections between layers.

- Ceramic Dam Technology: This unique technology ensures the precise alignment and sealing of holes, enhancing the PCB’s reliability.

- Oberflächenbehandlung: The PCB undergoes immersion gold plating to provide a corrosion-resistant surface finish.

Anwendungsszenarien

Aluminum Nitride Ceramic PCBs are ideal for various high-performance applications:

- High-Power Electronics: Suitable for use in power supplies, inverters, and other high-power electronic devices due to their excellent thermal management capabilities.

- High-Frequency Circuits: Perfect for RF and microwave circuits that require low loss and high stability.

- Medizinische Ausrüstung: Used in medical devices that demand precision, Zuverlässigkeit, and high-performance electronics.

- Luft- und Raumfahrt und Verteidigung: Ideal for applications in harsh environments where durability and thermal resistance are crucial.

Zusammenfassend, Aluminum Nitride Ceramic PCBs offer a combination of exceptional thermal conductivity, durability, and precision, making them ideal for high-performance electronics across various industries.

UGPCB-LOGO

UGPCB-LOGO