Einführung

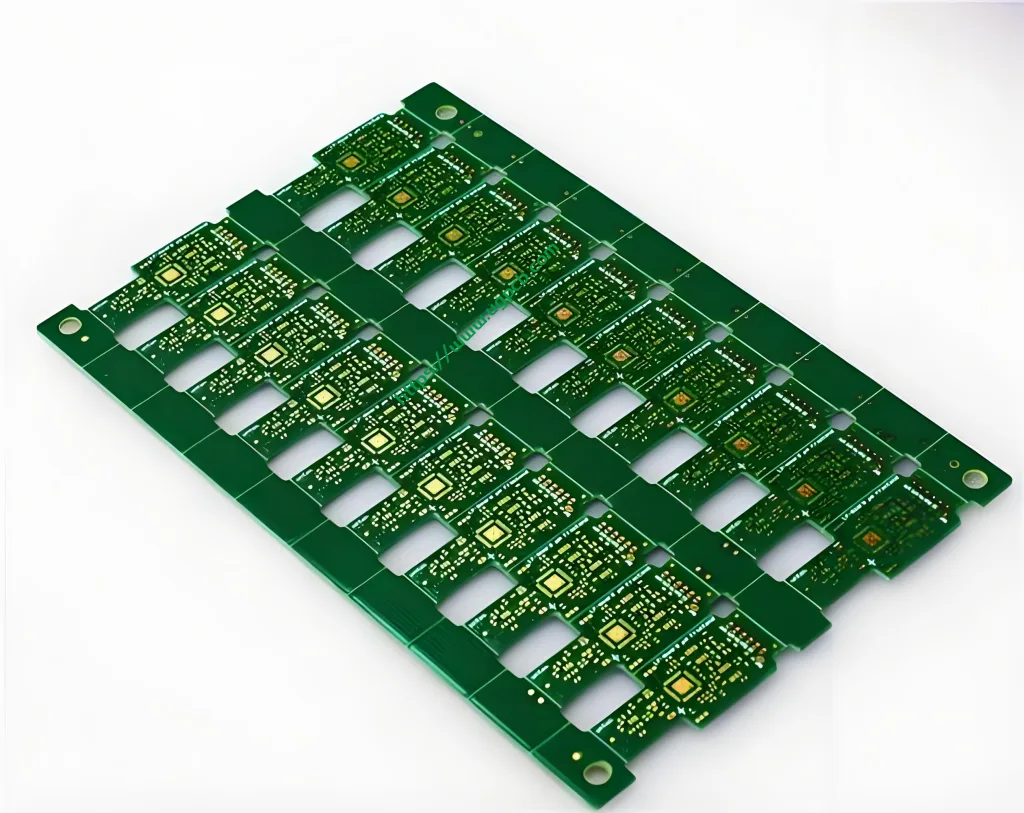

Dies ist eine doppelseitige Leiterplatte für die Massenproduktion (Leiterplatte) das von UGPCB ausgereift produziert wird. Wir versorgen Kunden mit kostengünstigen Leiterplatten und ermöglichen Kunden’ Produkte, um den Markt zu besetzen.

Arten von doppelseitigen Leiterplatten

Doppelseitige Leiterplatte (Leiterplatte) ist eine sehr wichtige Leiterplattenart. Auf dem Markt sind verschiedene Arten doppelseitiger Leiterplatten erhältlich, inklusive doppelseitiger Leiterplatte mit Metallbasis, Hi-Tg-Leiterplatte aus schwerer Kupferfolie, Flachwicklung Hochfrequenz-doppelseitige Leiterplatte, Hochfrequenz-Leiterplatte, Doppelseitige Hochfrequenz-Leiterplatte mit hybrider dielektrischer Basis, usw. Diese Leiterplatten eignen sich für eine Vielzahl von High-Tech-Branchen wie der Telekommunikation, Stromversorgung, Computer, Industrielle Steuerung, digitale Produkte, wissenschaftliche und pädagogische Ausrüstung, medizinische Ausrüstung, Automobile, Luft- und Raumfahrt, usw.

Zusammensetzung und Verwendung

Doppelseitige Leiterplatte (Leiterplatte) wird normalerweise aus Epoxidglas -Stoffkupfer -Verklemmungsbrett bestehen. Es wird hauptsächlich für elektronische Kommunikationsgeräte verwendet, Fortgeschrittene Instrumente, und elektronische Computer mit hohen Leistungsanforderungen.

Produktionsprozess

Der Produktionsprozess einer doppelseitigen Druckscheideplatte (Leiterplatte) wird im Allgemeinen in die Verfahrensmethode unterteilt, Lochblockierungsmethode, Maskierungsmethode, und Musterbeschichtungsmethode. Der Prozessfluss der Muster-Plattierungsmethode wird häufig verwendet.

Proofing- und Veredelungsprozesse

Doppelseitige Leiterplatte (Leiterplatte) Proofing erfolgt häufig mit Handwerkskunst. Zusätzlich, Prozesse wie den Kolophoniumprozess, OSP -Prozess, Vergoldungsprozess, Eintauchgold- und Silberbeschichtungsprozesse sind ebenfalls anwendbar.

Spezifische Veredelungsprozesse

Sprühdose -Prozess: Dies bietet ein gutes Aussehen mit einem silberweißen Pad, das leicht zu verzieren und löten zu können, und ist kostengünstig.

Sikkim -Prozess: Dies gewährleistet eine stabile Qualität und wird in der Regel in Fällen verwendet, in denen die Bindung von IC beteiligt ist.

Schaltungslayout

Der Unterschied zwischen einer doppelseitigen Druckscheideplatte (Leiterplatte) und eine einseitige gedruckte Leiterplatte (Leiterplatte) ist, dass die Schaltung der einseitigen PCB nur auf einer Seite der PCB liegt, Während die doppelseitige PCB Schaltungen auf beiden Seiten hat, durch Vias in der Mitte verbunden.

Produktionsparameter

Die Produktion einer doppelseitigen gedruckten Leiterplatte (Leiterplatte) unterscheidet sich von denen der einseitigen gedruckten Leiterplatte (Leiterplatte). Zusätzlich zum Produktionsprozess, Es gibt einen zusätzlichen Kupferversuchesprozess, Welches ist der Prozess der Schaltungsleitung auf beiden Seiten der Leiterplatte.

UGPCB-LOGO

UGPCB-LOGO