Company Introduction

Who We Are?

Shenzhen UGPCB Technology Co., Ltd. was founded in 1999. We are a manufacturer specialized in PCB Assembly (SMT, TAUCHEN, KI) and electronic product final assembly (EMS) for global customers in the top market.

Our Capabilities

We have more than 10 years of SMT manufacturing experience with well-appointed SMT, TAUCHEN, and assembly lines. We offer one-stop services including SMT, FPC, TAUCHEN, EMS, Schutzbeschichtung, Testen, final assembly, Komponentenbeschaffung, design, und Unterstützung für Peripherieprodukte. Our factory is equipped with high-speed and accurate SMT equipment, and we provide a range of SPI, AOI, IKT, FCT, Röntgen, ROHS, and aging testing for products. All our shop floors are dust-free, all lines are lead-free, and we are an ISO9001 certified company.

Our Market Focus

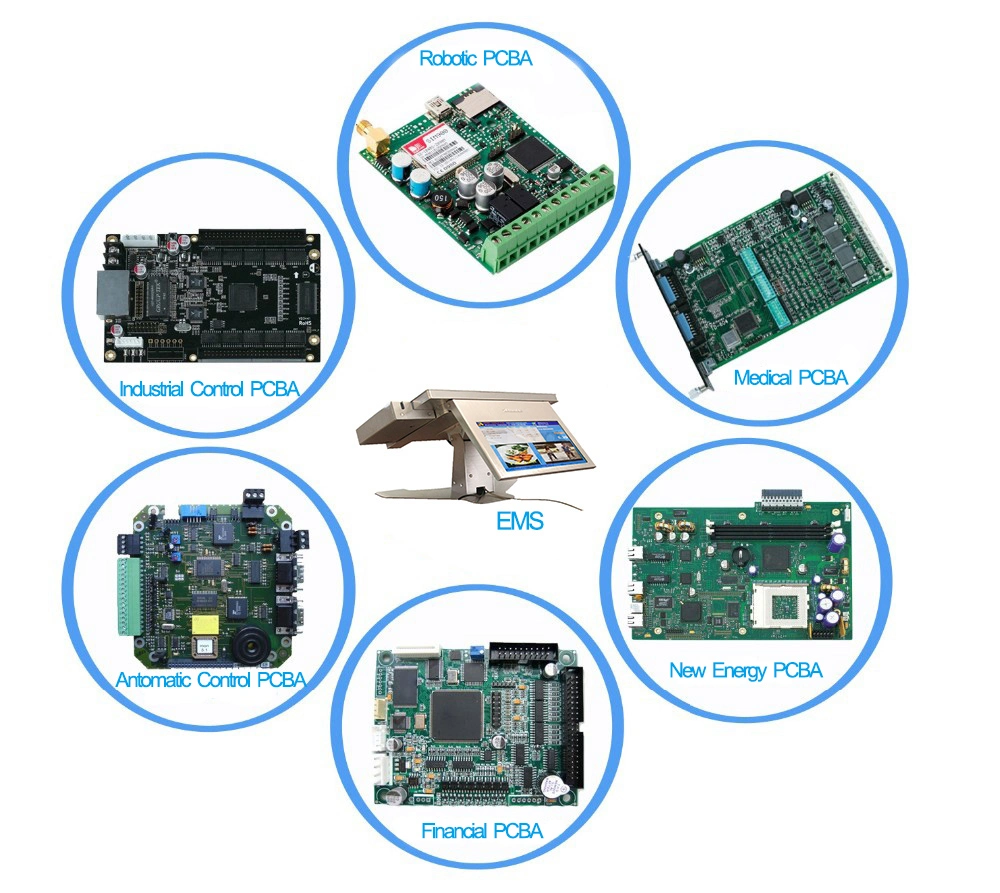

We provide BOM cost quotations with a high-quality control strategy and 8D analysis method. We focus on top-market customers, such as those in the medical, industriell, financial, robotic, Automobil, and New Energy sectors.

Our Clients

We service many global customers, including the leader in grain processing and solution provision, the top 3 medical industry customers in China, and the global leader in Telehealth Sensors.

Angebotene Dienstleistungen

PCB Capability and Services

- Types of PCBs: Single-sided, doppelseitig, and multi-layer PCBs; FPC; Flex Rigid PCB with competitive pricing, good quality, and excellent service.

- Materials: CEM-1, CEM-3 FR-4, FR-4 High TG, Aluminum base material, Polyimide, usw.

- Surface Treatments: HAL, HAL lead-free, Immersion Gold/Silver/Tin, OSP.

- Quantities: From sample to mass order.

- Testen: 100% E-Test.

SMT and DIP Services

- Material Sourcing: Material sourcing service.

- Montage: SMT assembly and through-hole component insertion.

- Testen: 100% AOI testing, IC pre-programming/burning on-line, ICT testing, and function testing as requested.

- Complete Unit Assembly: Including plastics, metal boxes, coils, cables, usw.

- Conformal Coating: Provided.

- OEM/ODM: Welcomed.

Production Capacity

PCB Capacity

- Max. Größe: Varies.

- DIP Capacity: Available.

- Min. Component Size: 0201.

- Min. Pin Space of IC: 0.3mm.

- Min. Space of BGA: 0.3mm.

- Max. Precision of IC Assembly: ±0.03mm.

- SMT Capacity: ≥2 million points/day.

- DIP Capacity: ≥100k parts/day.

EMS Capacity

- Electronic Product Final Assembly: 100k/month.

Why Choose Us?

High Quality

As an ISO9001 certified company, we have a robust quality system and professional quality team.

Zuverlässige Lieferkette

We have established long-term strategic cooperation with top electronic components manufacturers worldwide, such as Xilinx, VON, Avnet, und Zukunft. Our PCB can reach a max of 64 Schichten, with a minimum placement component size of 0201 and a minimum placement spacing of BGA of 0.3mm. We have complete inspection and testing for PCBA, including SPI, AOI, IKT, FCT, Röntgen, ROHS, and aging.

Schnelle Antwort

We offer fast and open BOM quotations to customers. With 10 years of cooperation experience with European and North American clients, we can quickly and professionally respond to customer requirements.

One-Stop Service

We professionally offer PCB Assembly (SMT, TAUCHEN, MI, KI), Komponentenbeschaffung, Endmontage des Produkts, Testen, PCBA-konforme Beschichtung, Elektronisches Produktdesign, und Unterstützung für Peripherieprodukte. Our factory is located in Shenzhen, and we have warehouses in Hong Kong, Europa, und Nordamerika. We can prepare boards at the warehouse closest to the customer and provide Kanban service according to customer requirements.

UGPCB-LOGO

UGPCB-LOGO