Überblick

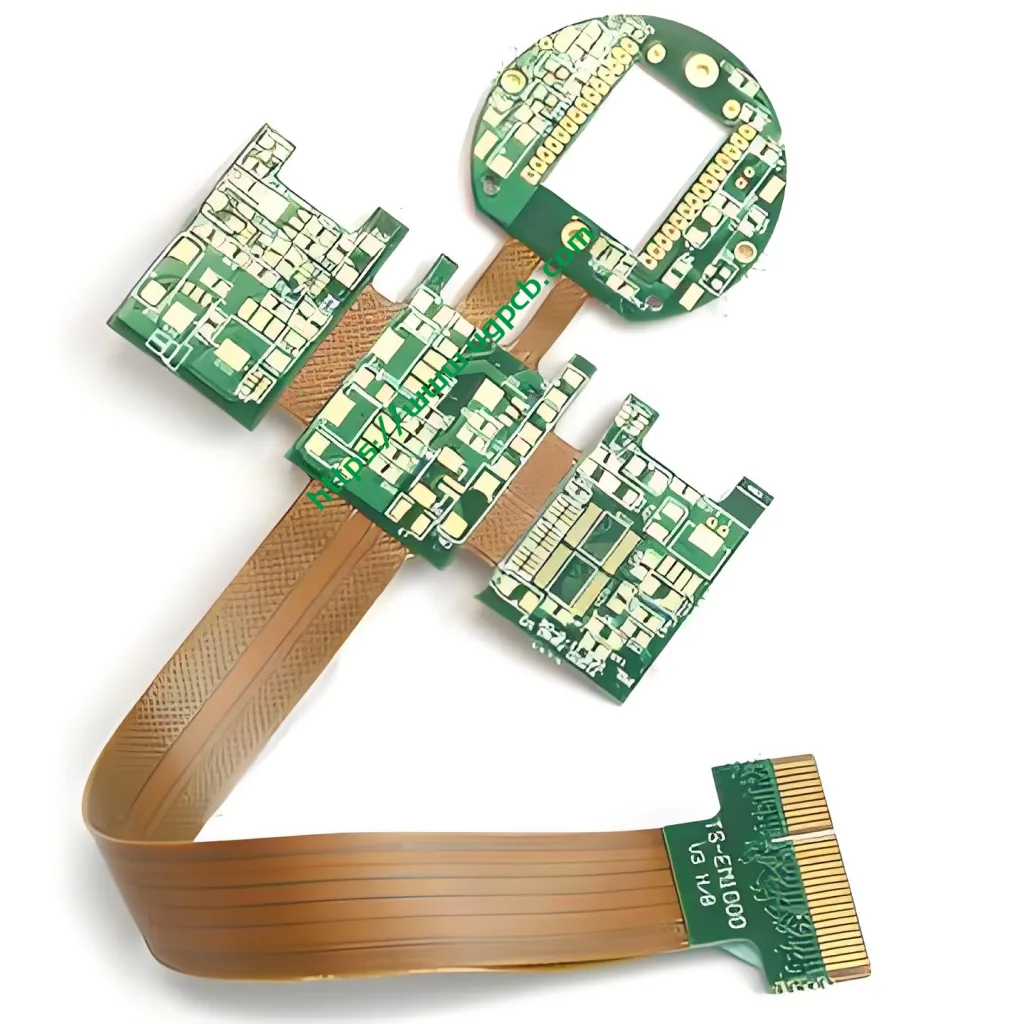

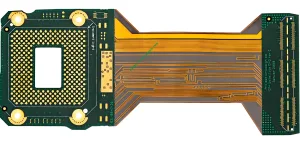

This Smart health assistant requires a smaller and thinner product to fit tightly to the body, and can detect the body’s blood pressure and heartbeat data in real time. daher, Starr-Flex-Leiterplatte (FPCB) is required to meet the product requirements.

Advantages of Rigid-Flex PCB (FPCB)

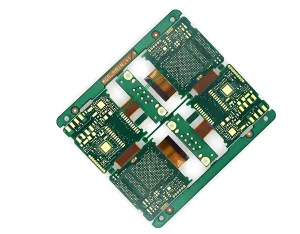

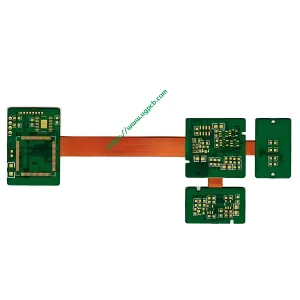

Space Savings and Cost Reduction

- It can effectively save PCB space and save the use of connectors or HotBar manufacturing process.

- Because the Rigid-Flex PCB (FPCB) is already integrated, the space that originally needed to use the connector or HotBar process can be saved.

- For some PCBs with high-density requirements, one less connector is needed.

- This also saves the cost of parts using the connector or the cost of the HotBar process.

- Zusätzlich, the space between the two PCBs can be made tighter by eliminating the need for connectors.

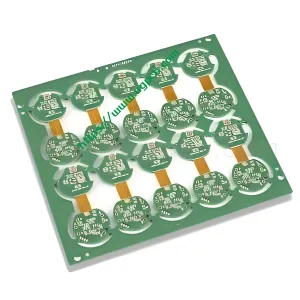

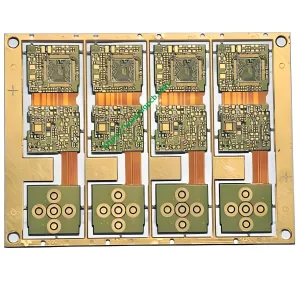

Improved Signal Transmission Reliability

- The signal transmission distance is shortened and the speed is increased, which can effectively improve the reliability.

- The traditional signal transmission through the connector is “PCB-connector-FPC-connector-PCB”, while with Rigid-Flex PCB (FPCB), the signal transmission is reduced to “PCB-FPC-PCB”.

- The problem of signal transmission attenuation between different media is also reduced.

- For some Products with higher signal accuracy requirements, Starr-Flex-Leiterplatte (FPCB) can help improve their reliability.

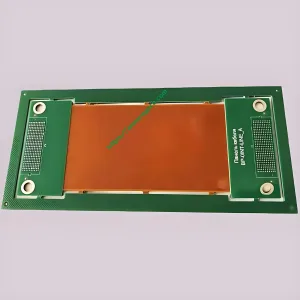

Simplified Product Assembly

- Simplify product assembly and save assembly man-hours.

- Using Rigid-Flex PCB (FPCB) can reduce the man-hours of SMT parts, because the number of connectors is reduced.

- It also reduces the man-hours for assembly of the whole machine, because it eliminates the assembly action of inserting the FPC into the connector, or eliminates the HotBar manufacturing process.

- It also reduces the cost of parts management and inventory, because the BOM is reduced, so the management becomes less.

Other Advantages

- It is flexible and can be wired three-dimensionally, and the shape can be changed according to space constraints.

- High and low temperature resistance, flame resistance.

- Foldable without affecting the signal transmission function.

- It can prevent electrostatic interference.

- Stable chemical changes, stability, und hohe Zuverlässigkeit.

- Facilitate the design of related products, reduce assembly man-hours and errors, and increase the service life of related products.

- The volume of the application product is reduced, the weight is greatly reduced, the function is increased, and the cost is reduced.

UGPCB-LOGO

UGPCB-LOGO