Introduction to RT/duroid 5880LZ

Rogers RT/duroid 5880LZ is a high-frequency PCB material designed for precise stripline and microstrip circuit applications.

Composition and Industry Reputation

ROGERS RT/duroid high-frequency circuit material is PTFE (including randomly filled glass or ceramic) composite PCB material, suitable for high-reliability applications such as aerospace. For a long time, the RT/duroid series has been a high-reliability PCB material with superior performance in the industry.

Material Characteristics

RT5880LZ Unique Properties

RT5880LZ unique filler provides the material with low density and lightweight characteristics to meet high-frequency performance and weight-sensitive application requirements. 5880LZ PCB material has a low dielectric constant, good consistency among different plates, and remains constant in a wide frequency range. The low dissipation factor extends the application of 5880LZ PCB materials to the Ku band and above.

Processing and Specification

RT 5880LZ PCB material is easy to cut and process. It has good tolerance to cold, hot solvents, or reagents used to etch printed circuits or electroplate edge lines and holes. When ordering RT 5880LZ Rogers PCB, it is particularly necessary to specify the dielectric thickness, deviation, type of electrolytic copper, and required copper thickness.

Detailed Characteristics and Advantages

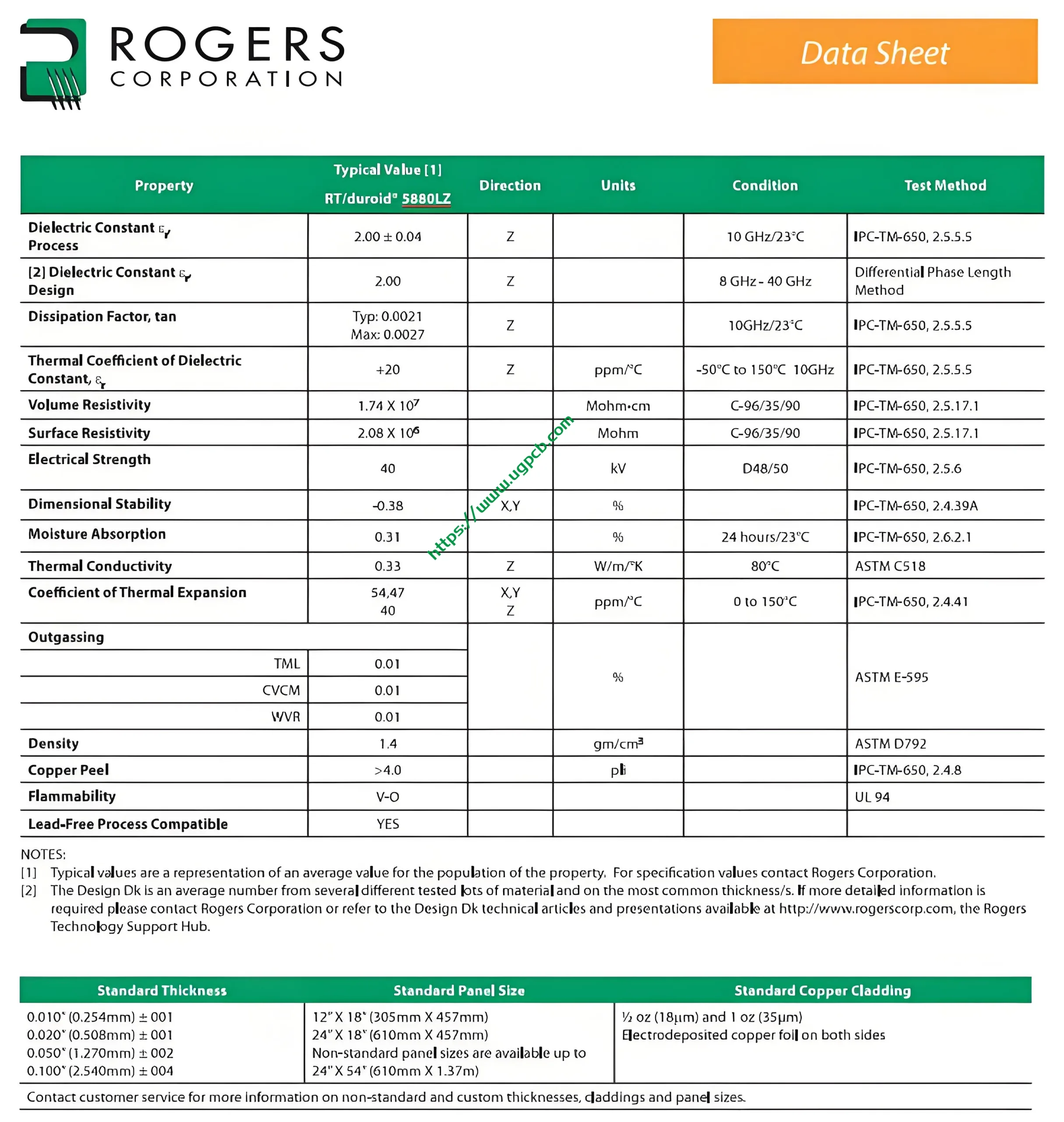

Characteristic Parameters

- Minimum dielectric constant, dielectric constant value 1.96

- Low Z CTE

- Low quality/low density, density only 1.4

- Electrical characteristics consistent with frequency

- Unique fillers can be made into low-density, lightweight materials for high-performance, weight-sensitive applications.

Structural Differences

The structure of RT/duroid 5880 is PTFE filled with random glass fibers. The fillers of RT/duroid 5880LZ are different in appearance, structure, and performance. The LZ of RT5880LZ refers to the small thermal expansion coefficient along the Z-axis. Compared with RT5880, it is filled with hollow silicon spheres, so it is lighter in weight, has a smaller Dk, and XYZ’s thermal expansion coefficient is close to that of copper. The thermal expansion coefficient of high-frequency plate RT/duroid 5880LZ is in the temperature range of 0-100 degrees, and XYZ’s triaxial thermal expansion coefficient is 44, 43, 41 respectively, which is suitable for making multilayer PCB boards.

Applications

RT/duroid 5880LZ PCB materials are typically used in aerospace antenna systems, lightweight feed networks, Militärische Radarsysteme, Raketenleitsysteme, point-to-point digital radio frequency antennas, precision stripline, microstrip circuit applications, leistungsstark, and weight-sensitive applications.

Performance and Processing

Dielectric and Loss Factors

The RT/duroid 5880LZ PCB material, synthesized from polytetrafluoroethylene (PTFE) material, uses unique filling technology and is designed for applications where the dielectric strip and microstrip lines are strictly required. It is a low-density, lightweight material and has wide application prospects in high-performance and weight-sensitive applications. The RT/duroid 5880LZ PCB material has a very low dielectric constant, Welches ist 1.96 +0.04 at a frequency band of 10 GHz and a temperature of 23 degrees C. The dielectric constants of PCB materials are also well consistent, remaining constant (value 1.96) over a wide frequency range (8 GHz to 40 GHz), so they are less affected by the frequency increase. The loss factor of RT/duroid 5880LZ PCB material is very low, with a typical value of 0.0019 and a maximum value of 0.0027. The low loss factor makes this type of PCB material suitable for the Ku band (12-18GHz) or even higher, greatly expanding its application range.

Processing Capabilities

RT/duroid 5880LZ PCB material is easy to cut and process and can be cut into the shape required for production according to design requirements. Gleichzeitig, it also has good corrosion resistance, effectively resisting the corrosion of solutions, reagents, hot and cold used in the process of etching printed circuits, edge plating, durch Löcher, usw., which greatly prolongs the life of PCB materials.

Manufacturing Capability

RT/duroid 5880LZ is a low-loss and high-reliability PTFE PCB board of Rogers Dk 2.0. It is difficult to make PTFE PCB materials. UGPCB can maturely produce high-frequency Rogers PCB with high difficulty.

UGPCB-LOGO

UGPCB-LOGO