S1150GH features

– Lead-free compatibility and excellent ion migration resistance

– Thermische Expansionskoeffizient für Z-Achse

– Halogenfreie PCB, antimony-free, red phosphorus free, and no other highly toxic and residual toxic components during waste combustion

– Applicable to high-end HDI performance processing requirements

S1150GH application field

– Unterhaltungselektronik

– Smartphones, Tabletten, laptops

– LED, Game device

S1150GH PCB Material

Halogen-free PCB Material Shengyi S1150GH

Halogen-free PCB material of Shengyi S1150G.

PCB material for halogen-free high reliability multilayer board: S1150GH+prepreg: S1150GHB PCB manufacturing precautions

1. S1150GH/S1150GHB storage conditions

1.1 S1150GH/S1150GHB copper clad plate

1.1.1 Speichermethode

Put it on the platform or suitable rack in the original packaging form to avoid heavy pressure and prevent deformation of the plate caused by improper storage.

1.1.2 Speicherumgebung

Die Platten sollten in einem belüfteten gelagert werden, Trocken- und Raumtemperaturumgebung, um direktes Sonnenlicht zu vermeiden, rain and corrosive gas erosion (the storage environment directly affects the plate quality). Double panels should be stored in a suitable environment for two years, and single panels should be stored in a suitable environment for one year. Die interne Leistung kann die Anforderungen des IPC4101 -Standards erfüllen.

1.1.3 Betrieb

Wear cleaning gloves to handle the plate carefully. Kollision, gleiten, usw. wird die Kupferfolie beschädigen, und bloßen Handbetrieb verschmutzen die Kupferfolienoberfläche. Diese Mängel können sich negativ auf die Verwendung der Platte auswirken.

1.2 Halbhärtungsblatt

1.2.1 Speichermethode

Store horizontally in the original packaging form to avoid heavy pressure and damage of the semi curing sheet caused by improper storage. The remaining roll shaped semi curing sheet after cutting shall be sealed and packed with fresh film and put back on the bracket in the original packaging.

1.2.2 Speicherumgebung

Der Prepreg muss in einem versiegelten Paket in einer Umgebung gelagert werden, die frei von ultraviolettem Licht ist. Die spezifischen Speicherbedingungen und die Speicherperiode sind wie folgt

Zustand 1: Temperatur<23 ℃, relative Luftfeuchtigkeit<50%, Speicherperiode von 3 Monate,

Zustand 2: Temperatur<5 ℃, Speicherperiode von 6 Monate,

The relative humidity has a great influence on the quality of the prepreg, and the corresponding dehumidification treatment should be carried out in humid weather. It is recommended to use the prepreg within 3 days after unpacking.

1.2.3 Schneiden

It is better for professionals to wear clean gloves for cutting to prevent the surface of the prepreg from being polluted. Die Operation sollte vorsichtig sein, um zu verhindern, dass das Prepreg falten oder falten. When PP is cut, the worktable should be cleaned first to avoid cross contamination of different types of PP resin powder.

1.2.4 Vorsichtsmaßnahmen

Wenn der Prepreg aus der Kühllagerung genommen wird, Es muss den Temperaturwiederherstellungsprozess durchlaufen, bevor das Paket geöffnet wird. Die Temperaturrückgewinnungszeit ist mehr als 8 Std. (Abhängig von den spezifischen Speicherbedingungen). The package can be opened after the same temperature as the ambient temperature. The prepreg that has been opened into sheets must be stored in Condition 1 oder Bedingung 2 und so schnell wie möglich verbraucht. After more than 3 Tage, Es muss erneut überprüft und verwendet werden, nachdem seine Indikatoren qualifiziert sind. After the roll shaped prepreg is opened, the remaining roll shaped mantissa shall be used, It is required to carry out sealed packaging of the original packaging degree and store it in Condition 1 oder Bedingung 2. Wenn es einen IQC -Inspektionsplan gibt, the prepreg shall be tested as soon as possible after receipt (Nicht mehr als 5 Tage) gemäß IPC-4101 Standard. If the prepreg is dehumidified before use, it is recommended to set the conditions for the dehumidification cabinet: Temperatur<23 ℃, relative humidity about 40%, and the upper limit of fluctuation shall not exceed 50%.

2. S1150GH/S1150GHB PCB processing suggestions

2.1 Schneiden

Es wird empfohlen, die Sägenmaschine zum Schneiden zu verwenden, gefolgt von Schermaschine. Note that cutting with roller knife may cause plate edge delamination, so as to avoid plate edge delamination due to tool wear and improper clearance.

2.2 Kernplattenbacken

According to the actual use situation, the core plate can be baked. If the core plate is baked after opening, it is recommended that the core plate be baked after a high-pressure water wash after opening to avoid the introduction of resin powder produced during the shearing process to the plate surface, was zu schlechtem Ätzen führen kann. It is recommended that the core plate be opened and baked at 150 ℃/2~4h. Beachten Sie, dass die Platte die Wärmequelle nicht direkt kontaktieren kann.

2.3 Browning of inner layer

S1150GH scheme is suitable for browning process.

2.4 Stapelung

Der Stapelprozess muss sicherstellen, dass die Stapelsequenz der Bindungsblätter konsistent ist, and the overturning action shall be avoided during the stacking process to reduce the problems such as warping, deformation and folding caused thereby.

The time from browning of core plate to pressing plate shall be controlled within 12 Std.. When the buffer material may have moisture absorption risk, it is recommended to dry it.

Due to the material characteristics, it is easy to carry static electricity. When stacking, pay special attention to the adsorption of foreign matters on PP.

In order to ensure good alignment effect of expansion and contraction during plate arrangement, it is recommended to use rivet riveting for fixation. If fusion is required, it is recommended to use electromagnetic heat fusion. Gleichzeitig, the best fusion effect parameters should be evaluated in detail. For other fusion methods, the PCB’s own conditions should be carefully evaluated for fusion effect to avoid layer deviation caused by poor fusion.

2.5 Laminierung

It is recommended to select the press plate with good vacuum pumping performance and vacuum valve sealing to avoid the entry of external moisture.

The recommended heating rate is 1.5~2.5 ℃/min (the material temperature is within the range of 80~140 ℃).

It is recommended that the laminating pressure be 350-430psi (Hydraulische Presse). The specific high pressure should be adjusted according to the structural characteristics of the plate (Die Anzahl der Prepregs und die Größe des Kleberfüllbereichs). It is recommended to turn to high pressure at 80-100 ℃.

Curing conditions: Temperatur 180 ℃, time more than 60min.

Cooling rate < 2 ℃/min.

The material temperature of hot pressing is less than 150 ℃.

If copper foil heat conduction press is used, Shengyi Company shall be informed in advance.

Wenn Isolierbretter oder Einzelpaneele in mehrschichtigen Boards verwendet werden, Die Isolierbretter oder Einzelpaneele müssen aufgeraut werden, bevor sie verwendet werden, oder doppelseitige Boards können in Einzelpaneele oder Isolierbretter für die Produktion geätzt werden.

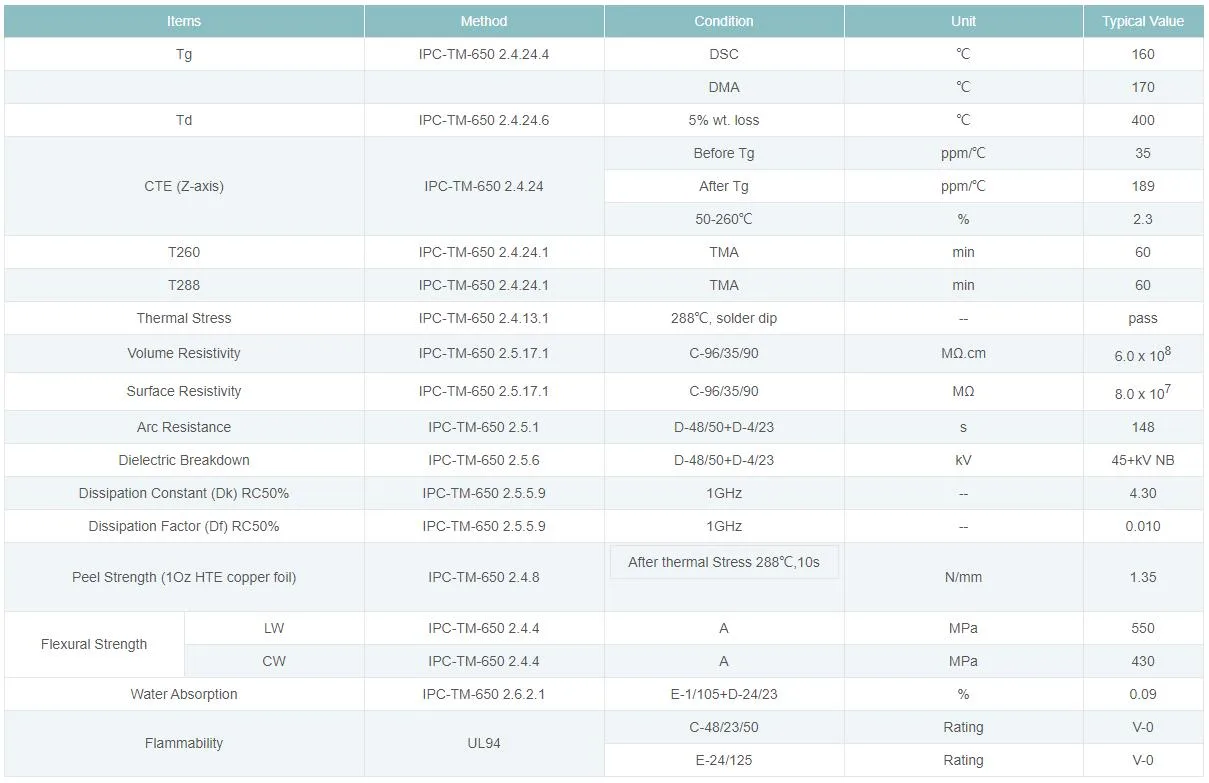

Shengyi S1150G Halogen-Free PCB material Specifications Table

2.6 Bohren

It is better to use a new drill.

The stack thickness is recommended to be no more than 2 pieces/stack (calculated as per the plate thickness of 1.6mm/block).

It is recommended to limit the drilling hole to 1000-2000 holes.

The feed rate for drilling shall be 15-20% lower than that for processing ordinary FR-4 materials.

2.7 Drying plate after drilling

It is suggested that the drying conditions after drilling should be 170-180 ℃/3h. Note that the plates should not be in direct contact with the heat source.

Baking before resin plug hole after back drilling: 170-180 ℃/2-3h.

2.8 Dirt removal

It is suggested that the specific parameters should be set according to the actual PCB structure (board thickness, aperture size), and all kinds of structural boards should be fully evaluated in detail to determine the best matching glue removal conditions and parameters. The glue removal effect should refer to the fact that there is no resin residue at the copper junction of the inner layer. The horizontal Desmear or vertical Desmear is recommended. The specific glue removal conditions are related to the equipment, liquid medicine model, board thickness or hole area. Under the premise of full load, the thicker the board is recommended, The longer the degumming time is.

2.9 Solder resistance ink

It is recommended that the drying plate before green oil: 130 ℃/2-4h,

Wenn Sie das Rack zum Backen verwenden, Wenn die Platte beim Einfügen des Racks gepresst oder deformiert wird, Nach dem Backen wird das Verziehen auftreten. It is not recommended to back wash the solder resist ink, which may cause white spots.

2.10 Zinnsprühen

It is suitable for lead-free tin spraying process. For the structure of thick copper and large copper surface on the outer layer (or thick copper plating), the temperature is high during lead-free tin spraying, resulting in excessive thermal stress, which is prone to white spots between large copper surfaces, copper skin warping and other problems. The improvement measures are as follows:

1. Try to reduce the tin spraying temperature, shorten the tin spraying time, and reduce the thermal stress generated during tin spraying,

2. Before tin spraying, pre bake the plate under the condition of 140-150 ℃/2h, and spray tin immediately to remove the moisture accumulated on the plate surface, which can reduce the probability of white spots,

3. Avoid too large tin spraying surface, or increase the thickness of green oil appropriately, which can well cushion the thermal stress generated during tin spraying,

4. The large copper surface structure is designed as a grid structure.

2.11 Profilverarbeitung

It is recommended to use a milling machine for processing and reduce the traveling speed appropriately. It is not recommended to use a beer plate for processing.

2.12 Verpackung

It is recommended to bake the plate before packaging under the condition of 120 ℃/4-6h to avoid heat resistance degradation caused by moisture. Aluminum foil vacuum packaging is recommended.

3. S1150GH/S1150GHB welding

3.1 Verpackungsgültigkeit

It is recommended to use vacuum aluminum foil bags for packaging, and the recommended period of validity is 3 Monate. Es ist besser, die Komponenten zu backen 120 ℃ for 4~6h before assembly.

3.2 S1150GH/S1150GHB reflow welding parameters

Suitable for conventional lead-free reflow soldering process.

Die Schweißtemperatur beträgt 350 ~ 380 ℃ (using temperature controlled soldering iron),

Schweißzeit des Einzelschweißpunkts: innerhalb 3 Sekunden.

UGPCB-LOGO

UGPCB-LOGO