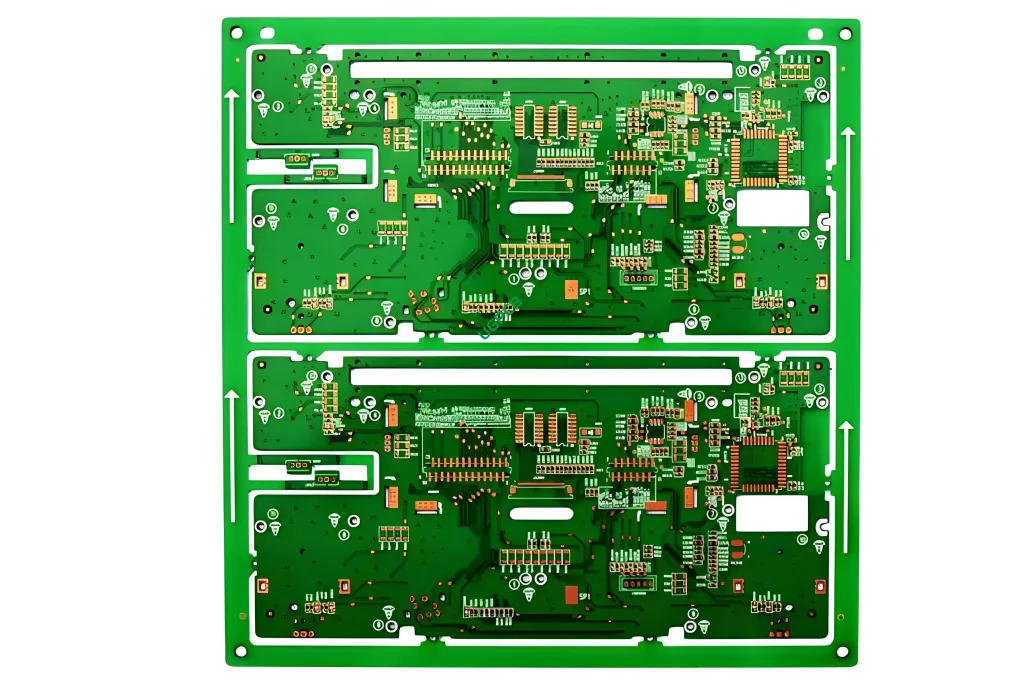

4-Layer Automotive Electronic PCB: A Comprehensive Guide

The 4-Layer Automotive Electronic PCB is a critical component in modern vehicles, designed to meet the rigorous demands of automotive electronics. This guide provides an in-depth look at this essential product, covering its definition, design requirements, working principles, applications, classifications, materiales, actuación, estructura, features, proceso de producción, and usage scenarios.

What is a 4-Layer Automotive Electronic PCB?

Definición

A 4-Layer Automotive Electronic PCB is a multilayered printed circuit board specifically engineered for use in automotive applications. It integrates various electronic components and facilitates their interconnection, ensuring reliable and efficient operation in vehicles.

Design Requirements

Designing a 4-Layer Automotive Electronic PCB involves several key considerations:

- Recuento de capas: Four layers provide sufficient complexity to handle advanced automotive electronics.

- Material: Made from Shengyi FR4, a high-quality flame-retardant material known for its durability and reliability.

- Espesor de cobre: The copper thickness is 1OZ, which ensures good electrical conductivity and heat dissipation.

- Tratamiento superficial: Immersion gold treatment enhances the PCB’s conductivity and resistance to corrosion.

- Minimal Trace/Space: With a minimum trace and space of 4mil(0.1milímetros), it allows for intricate circuit designs.

¿Cómo funciona??

The motherboard operates by integrating the CPU with various peripheral devices such as sensors, actuadores, and communication modules. It processes data from these devices and executes commands to control the robot’s actions. The immersion gold surface treatment enhances the electrical connections, Asegurar un rendimiento confiable.

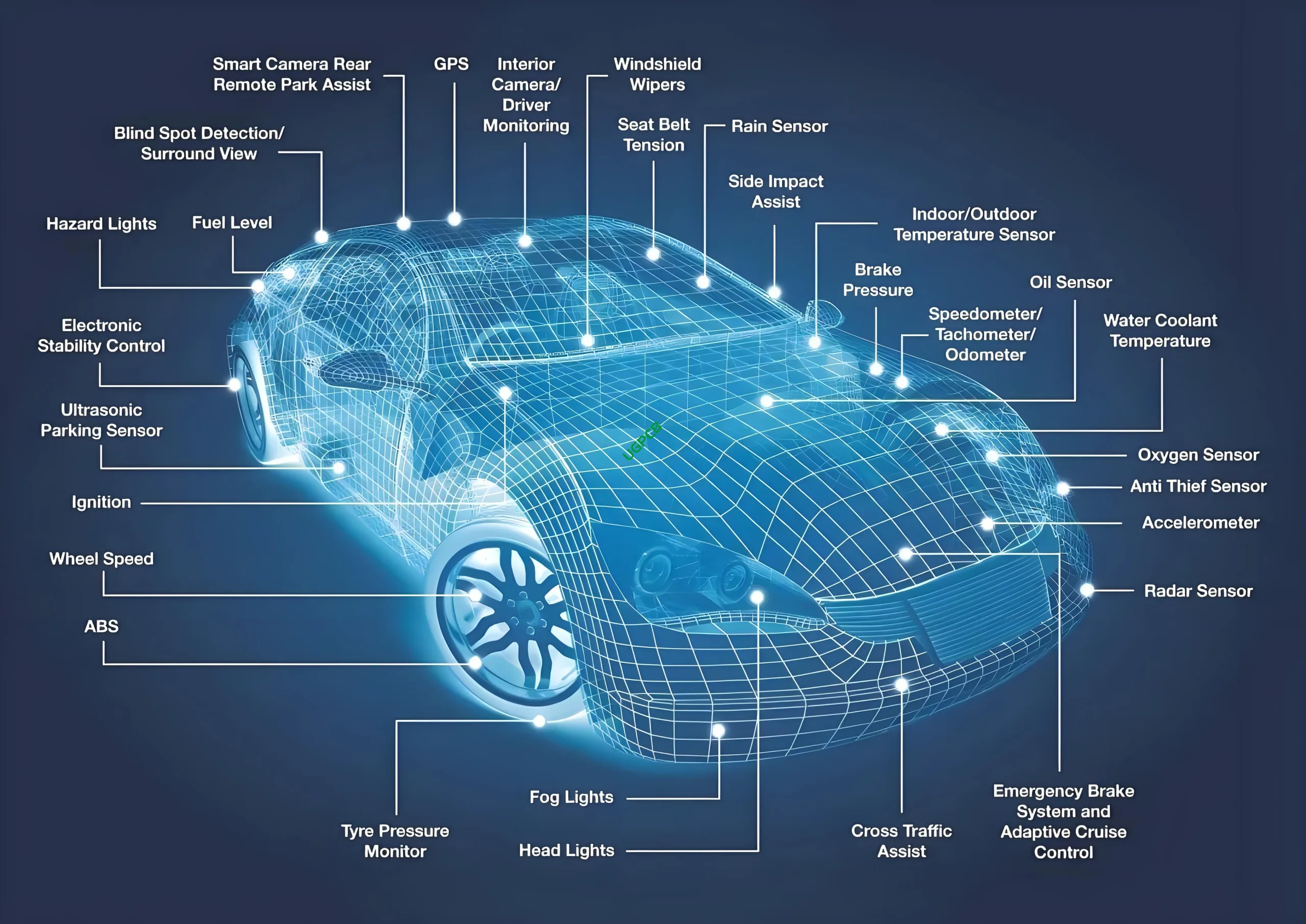

Aplicaciones

The 4-Layer Automotive Electronic PCB is used in various automotive electronic systems, incluido:

- Engine Control Units (ECUs): Managing engine performance.

- Infotainment Systems: Providing entertainment and navigation functions.

- Safety Systems: Enhancing vehicle safety through features like ABS and airbags.

- Body Control Modules (BCMs): Controlling various body functions like lighting and windows.

Types of 4-Layer Automotive Electronic PCBs

Different types of these PCBs can be categorized based on their specific applications and features:

- Standard Models: Suitable for general automotive electronics.

- High-Performance Models: Designed for demanding applications requiring superior performance.

- Customized Models: Tailored to meet specific needs and specifications of unique projects.

Material and Performance

The Shengyi FR4 material used in these PCBs offers excellent thermal and electrical properties, ensuring stable operation even under harsh automotive conditions. The green and white color scheme helps in identifying different sections during assembly.

Structure and Features

- Four Layers: Provides enhanced signal integrity and power distribution.

- Immersion Gold Treatment: Ensures long-lasting conductivity and resistance to corrosion.

- Thick Copper: With a copper thickness of 1OZ, it ensures good electrical conductivity and heat dissipation.

- Fine Trace/Space: With a minimum trace/space of 4mil(0.1milímetros), it allows for intricate circuit designs and higher component density.

Proceso de producción

The production process involves several stages:

- Diseño: Using advanced software to create the circuit layout.

- Fabrication: Corte, perforación, and etching the PCB layers.

- Asamblea: Placing and soldering components onto the board.

- Pruebas: Ensuring the PCB functions correctly and meets all specifications.

- Control de calidad: Final inspection to guarantee product reliability and performance.

Use Cases

- Automotive Manufacturing: Used by car manufacturers to integrate advanced electronics in vehicles.

- Aftermarket Upgrades: Enhancing vehicle functionality through aftermarket electronic systems.

- Research and Development: Used by engineers to develop new automotive technologies.

- Prototyping: Helping designers create functional prototypes before mass production.

En conclusión, the 4-Layer Automotive Electronic PCB is a highly specialized and essential component in the field of automotive electronics. Its design, material, and features are tailored to meet the demands of automotive applications, ensuring efficient and reliable performance across various scenarios.

UGPCB LOGO

UGPCB LOGO