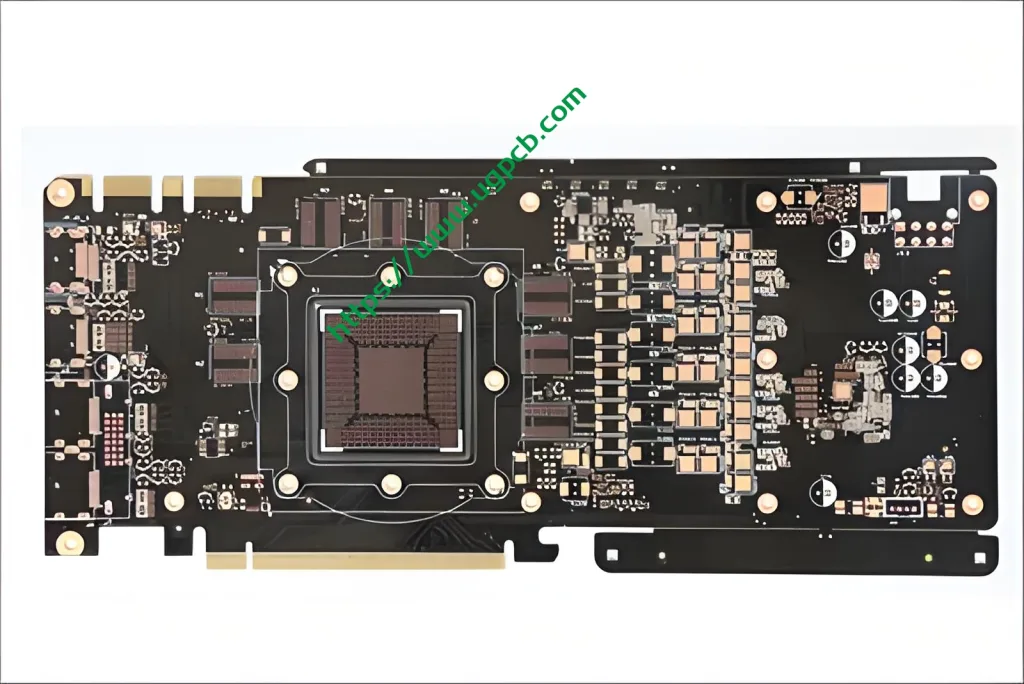

Computer Graphics Card PCB Product Overview

What is a Computer Graphics Card PCB?

A Computer Graphics Card PCB, or Printed Circuit Board, is a specialized electronic circuit board designed to house the components necessary for rendering graphics and images on a computer screen. It serves as the backbone of the graphics card, connecting various electronic components and facilitating the flow of electrical signals.

Definition and Functionality

The Computer Graphics Card PCB is essentially the motherboard of the graphics card. It provides the necessary connections and pathways for the GPU (Graphics Processing Unit), memory modules, power supply, and other essential components to communicate and function together. The PCB ensures that these components are properly interconnected, allowing the graphics card to process and render complex visual data efficiently.

Principio de trabajo

The working principle of a Computer Graphics Card PCB revolves around the transmission of electrical signals. When the computer sends a graphical command, the GPU processes this command and generates the corresponding signals. These signals are then transmitted through the conductive traces on the PCB to the various components, such as the memory modules and display connectors. The PCB acts as a medium for these signals to travel, ensuring that they reach their intended destinations accurately and efficiently.

Aplicaciones

Computer Graphics Card PCBs are primarily used in desktop and laptop computers to enhance their graphical capabilities. They are also found in gaming consoles, workstations, and other devices that require high-performance graphics processing. Además, they are used in professional fields such as graphic design, video editing, and 3D modeling, where powerful graphics capabilities are essential.

Clasificación

Computer Graphics Card PCBs can be classified based on several factors, including their layer count, material, and surface treatment. The layer count refers to the number of conductive layers within the PCB, with higher layer counts generally offering better performance and more complex circuitry. The material used for the PCB can vary, with common materials including FR4, CEM-1, and S1141. The surface treatment refers to the coating applied to the PCB’s surface, such as immersion gold or gold finger plating, which helps improve conductivity and protect against corrosion.

Composición de materiales

The Computer Graphics Card PCB is made using a specific material known as S1141. This material is chosen for its excellent electrical properties, thermal stability, and mechanical strength. It provides a reliable and durable platform for the graphics card’s components, ensuring optimal performance and longevity.

Características de rendimiento

The performance of a Computer Graphics Card PCB is influenced by several factors, including its layer count, espesor de cobre, and minimum trace/space. En este caso, the PCB has a layer count of 6 capas, providing ample space for complex circuitry and efficient signal routing. The copper thickness is 1OZ, which refers to the weight of the copper foil used in the PCB’s conductive layers. A thicker copper layer generally offers better electrical conductivity and heat dissipation. The minimum trace and space are both 3mil(0.075milímetros), indicating the smallest width and gap between conductive traces on the PCB. Smaller traces and spaces allow for more intricate and compact circuit designs, enhancing the overall performance of the graphics card.

Características estructurales

The Computer Graphics Card PCB features a gold finger electroplating hard gold characteristic. Gold finger plating involves coating the edges of the PCB with a layer of gold, which improves connectivity and reduces the risk of signal loss or interference. Hard gold plating provides additional durability and resistance to wear and tear, ensuring a reliable connection between the graphics card and the motherboard or other devices.

Proceso de producción

The production process of a Computer Graphics Card PCB involves several steps, including design, fabrication, y montaje. The design phase involves creating the电路图 (schematic) and layout of the PCB, taking into account the placement of components, trace routing, and other design considerations. Once the design is finalized, the fabrication phase begins, which includes etching the copper layers, drilling holes for component leads, and applying the surface treatment. Finalmente, during the assembly phase, the components are soldered onto the PCB, and any necessary testing and inspection are conducted to ensure the quality and functionality of the finished product.

Use Cases

Computer Graphics Card PCBs are used in a wide range of scenarios where high-performance graphics processing is required. They are commonly found in gaming rigs, where they provide the necessary power to render realistic and immersive gaming experiences. They are also used in professional workstations for tasks such as graphic design, video editing, and animation, where precise and detailed visual representation is crucial. Además, they are utilized in virtual reality systems, medical imaging equipment, and other applications that demand advanced graphical capabilities.

UGPCB LOGO

UGPCB LOGO