Composición de materiales

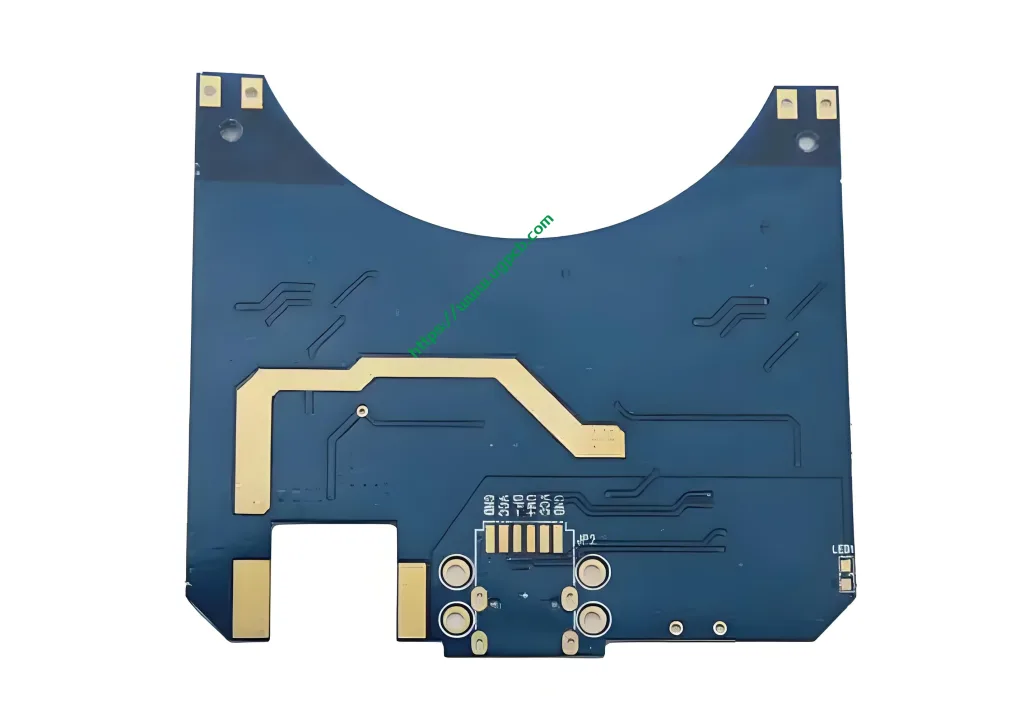

The Dark Blue 2 Layer PCB is constructed using high-quality FR4 (Retardante de llama 4) material. FR4 is known for its excellent electrical properties, resistencia mecánica, y resistencia al calor, making it ideal for a wide range of applications.

Presupuesto

This PCB features a sleek dark blue color with white silkscreen for a professional appearance. It has a finished thickness of 1.2mm, ensuring durability and stability. The copper thickness is 1OZ, providing sufficient conductivity for electrical signals. El tratamiento de la superficie es de oro de inmersión, which enhances corrosion resistance and improves solderability.

Características de rendimiento

With a minimum trace width and spacing of 4mil (0.1milímetros), the Dark Blue 2 Layer PCB supports high-density circuit layouts. This makes it suitable for complex electronic designs that require precise and reliable connections. The immersion gold finish further enhances its performance by providing a protective layer that prevents oxidation and ensures long-term reliability.

Proceso de producción

The production of Dark Blue 2 Layer PCBs involves several steps:

- Design and Layout: The PCB design is created using specialized software and then reviewed for accuracy.

- Preparación de material: FR4 sheets of the required thickness are cut to size.

- Copper Lamination: A layer of copper is applied to both sides of the FR4 sheet.

- Aguafuerte: The unwanted copper is removed to create the circuit pattern.

- Perforación: Holes are drilled for components and interconnections.

- Enchapado: The holes are plated with copper to ensure electrical conductivity.

- Tratamiento superficial: An immersion gold finish is applied to protect the copper surfaces.

- Silkscreen Printing: Component labels and other markings are printed on the PCB.

- Assembly and Testing: Components are assembled, and the PCB is tested to ensure functionality.

Escenarios de aplicación

The Dark Blue 2 Layer PCB is ideal for a variety of digital applications, incluido:

- Electrónica de Consumo: Such as smartphones, tabletas, and wearable devices.

- Computer Hardware: Including motherboards, tarjetas graficas, and other computer components.

- Controles industriales: For automation systems, sensores, and other industrial equipment.

- Telecomunicaciones: In routers, interruptores, and other networking devices.

Conclusión

The Dark Blue 2 Layer PCB offers a combination of high-quality materials, precise specifications, and excellent performance, making it a versatile choice for a wide range of digital applications. Its robust construction and reliable surface treatment ensure long-term durability and reliability, making it an excellent investment for any electronic project.

UGPCB LOGO

UGPCB LOGO