Low CTE and High Modulus

- Low CTE and high modulus, which can effectively reduce the warpage of the package carrier

- Excellent heat and humidity resistance

- Good PCB processability

-

Halogen-free materials

Application Field

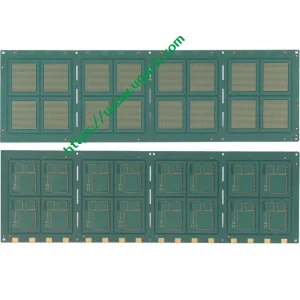

eMMC and DRAM

- eMMC, DRAM

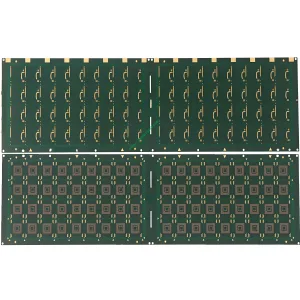

AP and PA

- AP, PA

Dual CM

- Dual CM

Fingerprint and RF Module

- Fingerprint, módulo de radiofrecuencia

Thermal and Mechanical Properties

- tg (DMA): 280 degree Celsius

- td (5% wt. loss): >400 degree Celsius

- CTE (X/Y-axis) before Tg: 10 ppm/degree Celsius

- CTE (Eje Z) α1/α2: 25/135 ppm/degree Celsius

- Constante dieléctrica (1GHz): 4.4

- Factor de disipación (1GHz): 0.007

- Fuerza de pelado (1/3 ONZ, VLP Cu): 0.80 N/mm

- Solder Dipping (@288 degree Celsius): >30 mín.

- Young’s modulus (50 degree Celsius): 26 GPa

- Young’s modulus (200 degree Celsius): 23 GPa

- Flexural Modulus (50 degree Celsius): 32 GPa

- Flexural Modulus (200 degree Celsius): 27 GPa

Water Absorption and Flammability

- Water Absorption (A): 0.14%

- Water Absorption (85 degree Celsius/85%RH, 168Hr): 0.35%

- Inflamabilidad (UL-94): V-0

Other Properties

- Conductividad térmica: 0.61 W/(m.K)

- Color: Negro

Introducción

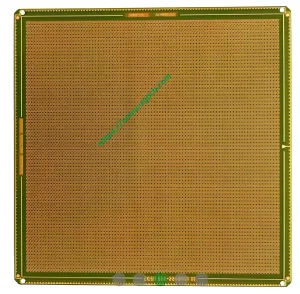

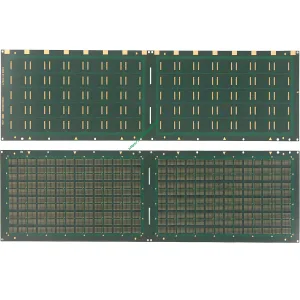

IC carrier board packaging frame refers to a key special basic material used for IC card module packaging. It mainly protects the chip and serves as the interface between the integrated circuit chip and the outside world. Its form is ribbon, usually golden yellow.

Usage Process

The specific usage process is as follows: Primero, the IC card chip is attached to the IC card packaging frame by a fully automatic placement machine, and then the contacts on the IC chip are connected to the nodes on the IC card packaging frame with a wire bonding machine. The connection of the circuit, and finally the use of packaging materials to protect the integrated circuit chip to form an integrated circuit card module, which is convenient for subsequent applications.

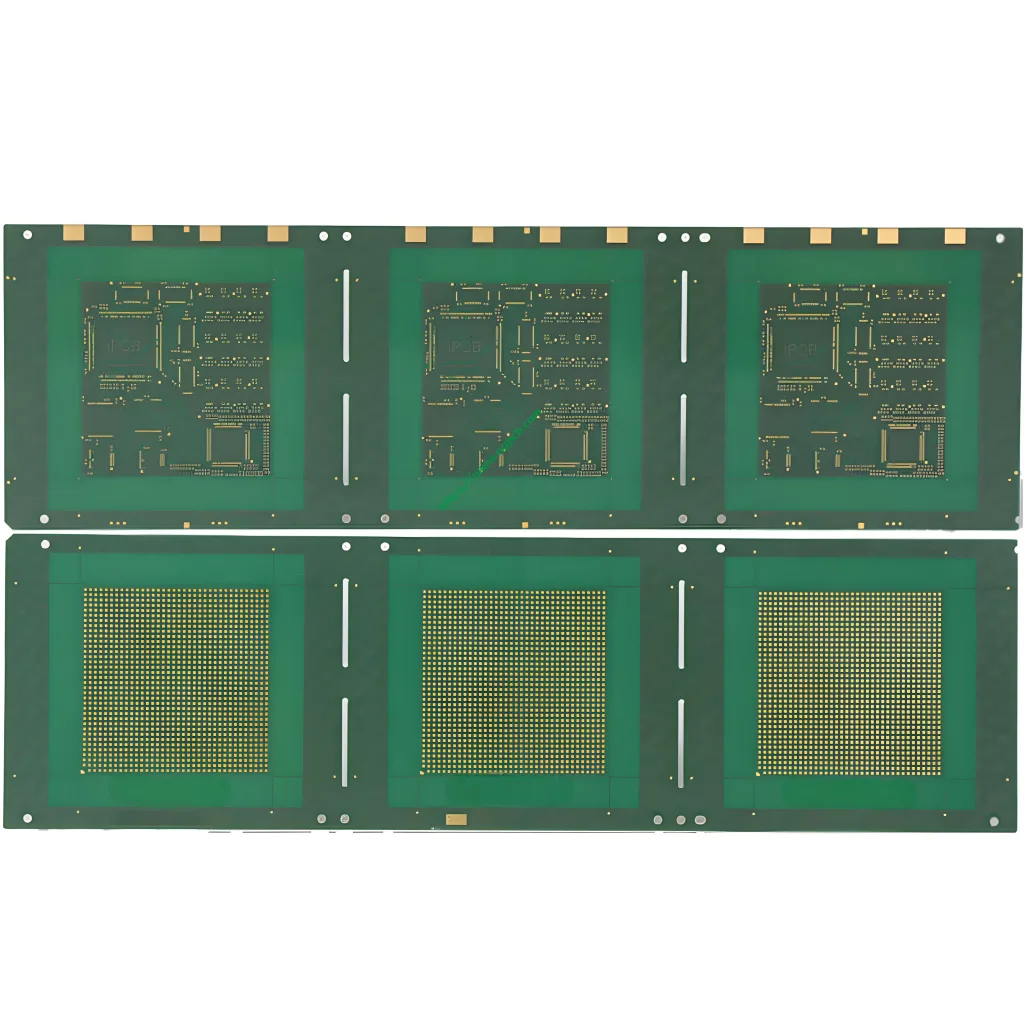

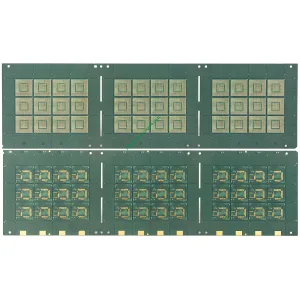

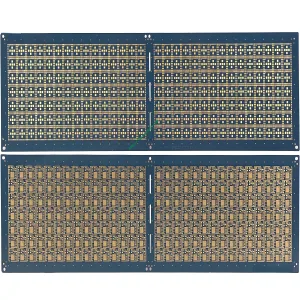

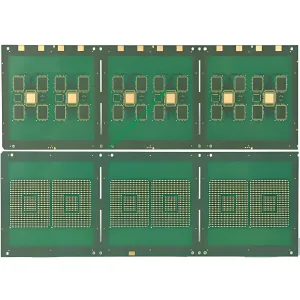

BGA Architecture and Manufacturing Process

The IC carrier board is also a product based on the BGA (Matriz de rejilla de bolas) architecture. The manufacturing process is similar to that of PCB products, but the precision is greatly improved. The manufacturing process is different from PCB. IC substrate has become a key component in IC packaging, gradually replacing part of the lead frame (Lead Frame) solicitud.

Circuito Integrado

An integrated circuit integrates a general-purpose circuit on a chip. It is a whole. Once it is damaged internally, the chip is also damaged.

Placa de circuito impreso

The PCB can solder the components by itself, and replace the components if it is broken.

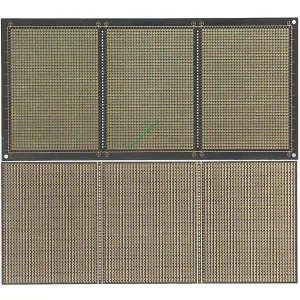

IC Carrier Board

Generalmente, the carrier board on the chip, the board is very small, usually the size of a 1/4 fingernail, the board is very thin (0.2~0.4mm), the material used is FR-5, BT resin, and the circuit is 2mil/About 2mil. It is a high-precision board that used to be generally produced in Taiwan, but now it is trending towards the mainland. The industry’s yield rate is 75%. The unit price of this kind of board is very high, generally bought according to PCS.

UGPCB LOGO

UGPCB LOGO