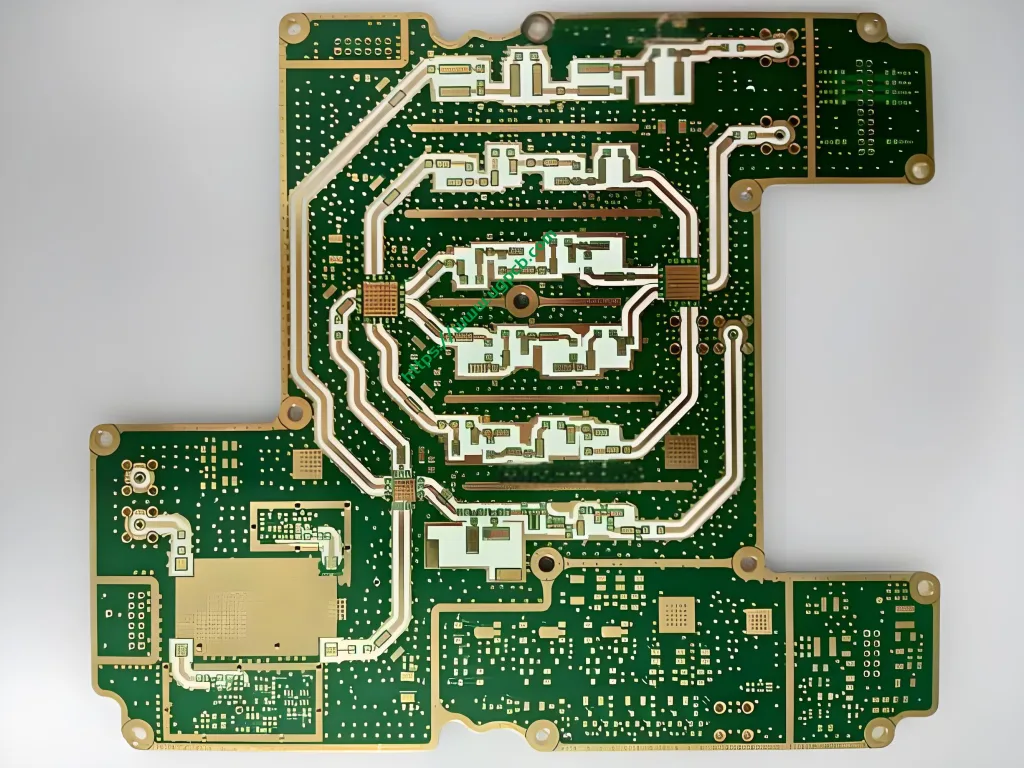

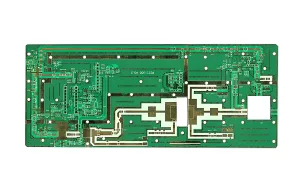

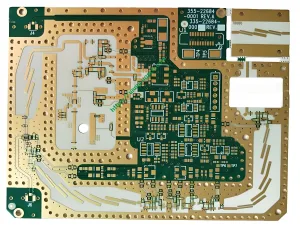

Introduction to Embedded Copper Plate

As high frequency RF (radio frequency) and PA (amplificador de potencia) and other high-power electronic components have higher requirements for PCB heat dissipation capacity, the industry began to introduce the manufacturing process of embedding copper block in PCB, which is called embedded copper plate. Al mismo tiempo, in order to save the material cost of high-frequency materials, only the RF circuit part is designed to be mixed with high-frequency materials. Actualmente, most of the products are combined with these two processes at the same time. The high-frequency material and heat dissipation copper block after the single-sided circuit is fabricated are embedded after lamination. Al mismo tiempo, the heat dissipation copper block also needs to be machined to produce the corresponding power amplifier element placement slot.

Heat Dissipation Requirements for PCB

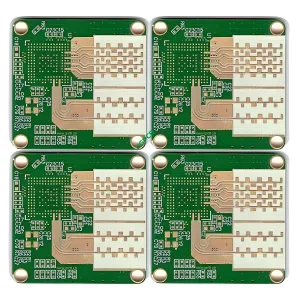

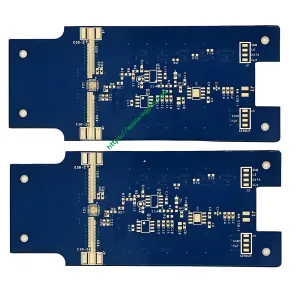

High Current Coil Board

For PCB (placa de circuito impreso), when it involves high current coil board, it has high requirements for heat dissipation performance. Generalmente, copper block is embedded in PCB to meet the heat dissipation requirement.

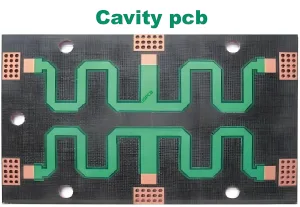

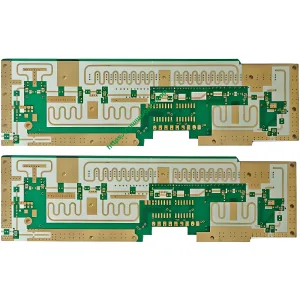

Existing Copper Embedded PCB Structure

The existing copper embedded PCB includes copper block and PCB core board with copper groove. The copper block is embedded in the copper groove, and the top surface of PCB core board and copper block are connected with copper foil layer through film. In the copper embedded PCB, if the copper block and copper slot are the same size, there is no glue filling between the side wall of the copper block and the PCB core board, and the adhesion between the copper block and the PCB core board is small, and the copper block is easy to fall off.

Improving Adhesion Between Copper Block and PCB Core Board

Matching Gap for Improved Adhesion

In order to improve the adhesion between the copper block and the PCB core board, the size of the directly embedded copper block generally needs to be slightly smaller than that of the copper insert groove, eso es, the gap between the side wall of the copper block and the side wall of the copper groove is matched, so that the film can fill the gap between the side wall of the copper block and the side wall of the copper insert groove during the pressing process, so as to improve the adhesion between the copper block and the PCB core board.

Addressing Loose and Falling Off of Copper Block

Aún así, if the copper block is one-sided pressed, eso es, the top surface of the copper block is pressed with the film, and the bottom surface of the copper block is exposed, the bare bottom surface of the copper block has no support. Relying only on the adhesion of the top film and the adhesive in the gap, the copper block is easy to loose and fall off.

Preventing Horizontal Movement of Copper Block

Al mismo tiempo, because the gap between the side wall of the copper block and the side wall of the copper insert groove is matched, the glue is squeezed into the gap during the pressing process, which may cause the copper block to move horizontally and deviate from the center position.

UGPCB LOGO

UGPCB LOGO