A Vehicle Communication System is a computer network in which vehicles and roadside units are communication nodes, providing information to each other, such as safety warnings and traffic information. They can effectively avoid accidents and traffic jams. Both types of nodes are dedicated short-range communications (DSRC) devices. DSRC operates in the 5.9 GHz band with a bandwidth of 75 MHz and a range of approximately 300 medidores (980 feet). [1] In-vehicle communications are often developed as part of an Intelligent Transportation System (ITS).

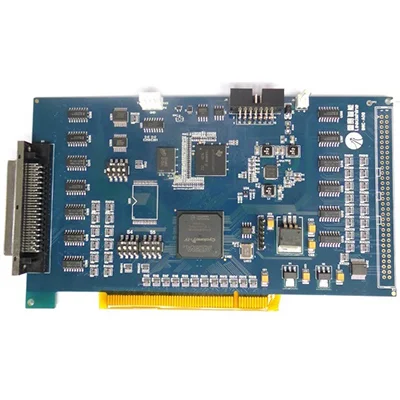

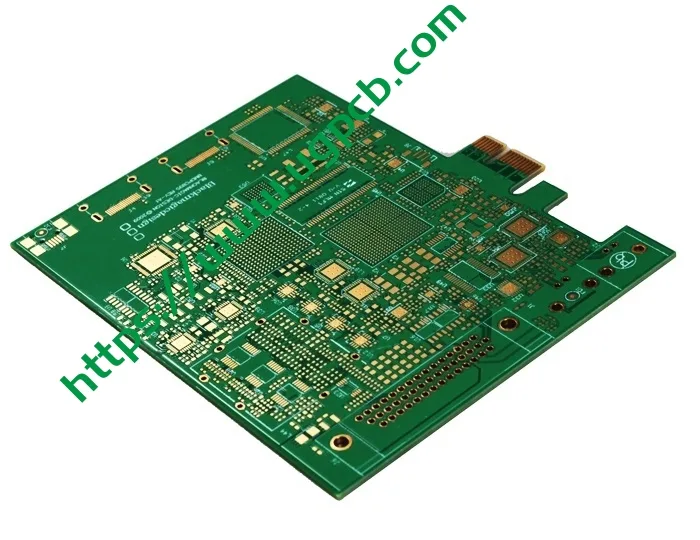

We provide In-vehicle communication system PCB Assembly, Turnkey PCB Assembly services. UGPCB is your one-stop Turnkey PCB Assembly company.

Improve the control integration of the whole vehicle, reduce the electric wiring harness of the body, improve the signal transmission accuracy, and facilitate maintenance. The in-vehicle network is an early communication between the internal sensors, controls, and actuators of the car, which is connected into a complex network structure by means of point-to-point connections.

With the increasing complexity of the electronic control system and the increasing requirements for the communication capabilities between the electronic control units of the car’s internal control functions, the use of point-to-point links will increase the number of wiring harnesses in the car. Por lo tanto, considering the reliability, seguridad, and weight of internal communication, all aspects have brought great troubles to the design and manufacture of automobiles. To reduce in-vehicle connections to achieve data sharing and rapid exchange, while improving reliability, etc., on the rapidly developing computer network, the automotive electronic network system with basic structures such as CAN, LAN, LIN, and MOST—that is, the in-vehicle network—has emerged.

The intelligent function of the vehicle’s information transmission network system can directly display various faults generated by the system and convert the detected faults into codes and store them for calling during maintenance. Because the information transmission network system can provide a general diagnostic interface for fault diagnosis, it provides great convenience for maintenance personnel to use the multi-function tester to test and diagnose the data stored in the electronic control unit.

The vehicle network system refers to the connection of numerous control modules or (nodos) in the vehicle by means of communication media such as twisted pair, coaxial cable, or optical fiber, so that several sensors, actuadores, and electronic control units (ECUs) share common data channels. These shared transmission channels and data are managed by the network controller through a certain communication protocol. The in-vehicle network system reduces the use of wire harnesses, improves the flexibility of the system, and can realize system function changes and data sharing through the system software. It also improves the ability to diagnose system faults. Por ejemplo, the in-vehicle network can transmit the driving status parameters of the car to the display screen to improve driving safety.

We provide In-vehicle communication system PCB Assembly, Turnkey PCB Assembly services. UGPCB is your one-stop Turnkey PCB Assembly company.

UGPCB LOGO

UGPCB LOGO