Overview of Electroless Nickel Palladium Gold

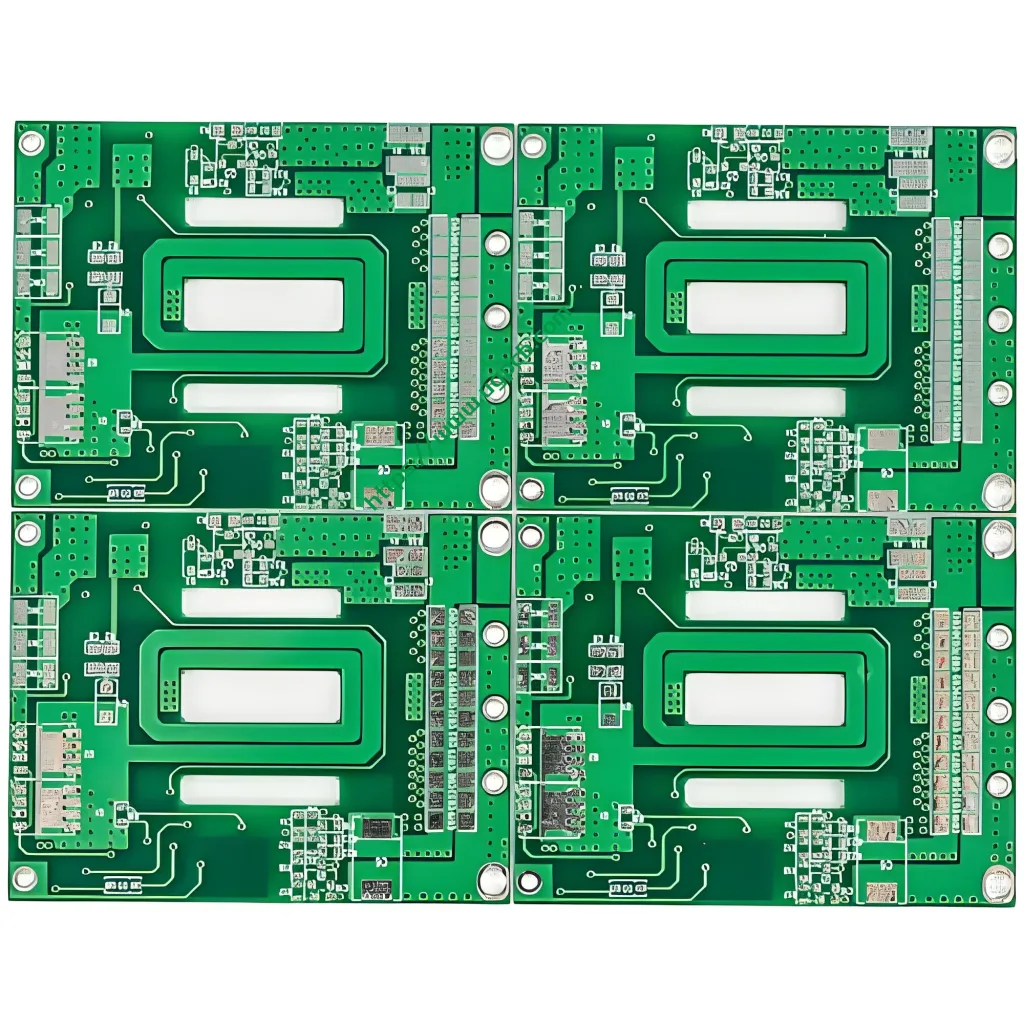

Electroless nickel palladium gold is an important surface treatment process in the printed circuit board industry. It is widely used in the production process of hard circuit boards (tarjeta de circuito impreso), flexible circuit boards (FPC), rigid scrambling boards, and metal substrates. It is also an important development trend of surface treatment in the printed circuit board industry in the future.

Process and Mechanism

Electroless nickel palladium gold is a non-selective surface treatment technology that deposits a layer of nickel, palladium, and gold on the surface of the copper layer of the printed circuit by chemical methods. The main process flow is:

- Degreasing

- Micro-etching

- Pre-dipping

- Activation

- Nickel plating

- Palladium plating

- Gold plating

- Drying

There will be multi-stage washing treatment between each link. The mechanism of electroless nickel-palladium-gold reaction mainly includes redox reaction and displacement reaction. entre ellos, the reduction reaction is easier to deal with thick palladium and thick gold products.

Actualmente, the production specifications of chemical nickel, palladium, and gold in general factories are: nickel 2-5um, palladium 0.05-0.15um, and gold 0.05-0.15um. Por supuesto, due to differences in plant equipment and reaction mechanisms, the uniformity of chemical reactions and the ability to handle thick palladium and thick nickel are also different.

Comparison with Electroplating Nickel Gold

Application and Production Capacity

Electroless nickel palladium gold is also an important surface treatment process in the field of printed circuit boards. The main application field is wire bonding technology, which can cope with high-end electronic circuit products to a certain extent.

Although chemical nickel-palladium-gold has a slow reaction speed, since it does not require the connection of lead wires and electroplating wires, the number of products produced simultaneously in the same volume of tank is much larger than that of electroplating nickel-gold. De este modo, it has a very large overall production capacity advantage.

Development Trend

As mentioned earlier, the main advantage of electroless nickel palladium gold is to deal with the surface treatment of high-end products and fine circuits. Sin embargo, the development of electronic technology and its attendant demands are also growing rapidly. Actualmente, the common chemical nickel-palladium-gold process will gradually become incapable of coping with the production of high-precision circuits.

Por lo tanto, in order to cope with higher demand, the current main development direction is thin nickel palladium gold technology and chemical palladium gold technology. These technologies are widely used in communication, electrónica de consumo, controles industriales, seguridad, automóvil, power supply, hogar inteligente, médico, militar, y otras industrias.

UGPCB LOGO

UGPCB LOGO