Introduction to Rogers RO4350B PCB Board for Anti-Collision of Cars

Composición de materiales

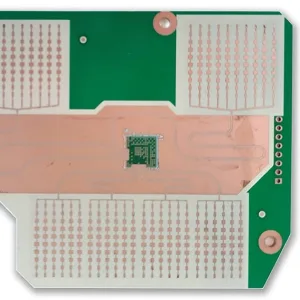

The Rogers RO4350B PCB Board for Anti-Collision of Cars is crafted using a unique blend of Rogers RO4350B and FR4 mixed dielectric materials. This combination ensures a robust and reliable foundation for high-frequency applications, making it ideal for advanced automotive technologies.

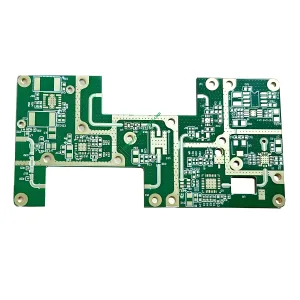

Características de rendimiento

With a dielectric constant (D K) de 3.48, the RO4350B PCB Board exhibits stable electrical properties across a wide range of frequencies. Its finished thickness of 1.6mm and copper thickness of 1OZ provide excellent durability and conductivity. The dielectric thickness of 0.127mm supports precise signal transmission, while the thermal conductivity of 0.69w/m.k ensures efficient heat dissipation. The board’s flammability rating of 94V-0 guarantees safety in various environments.

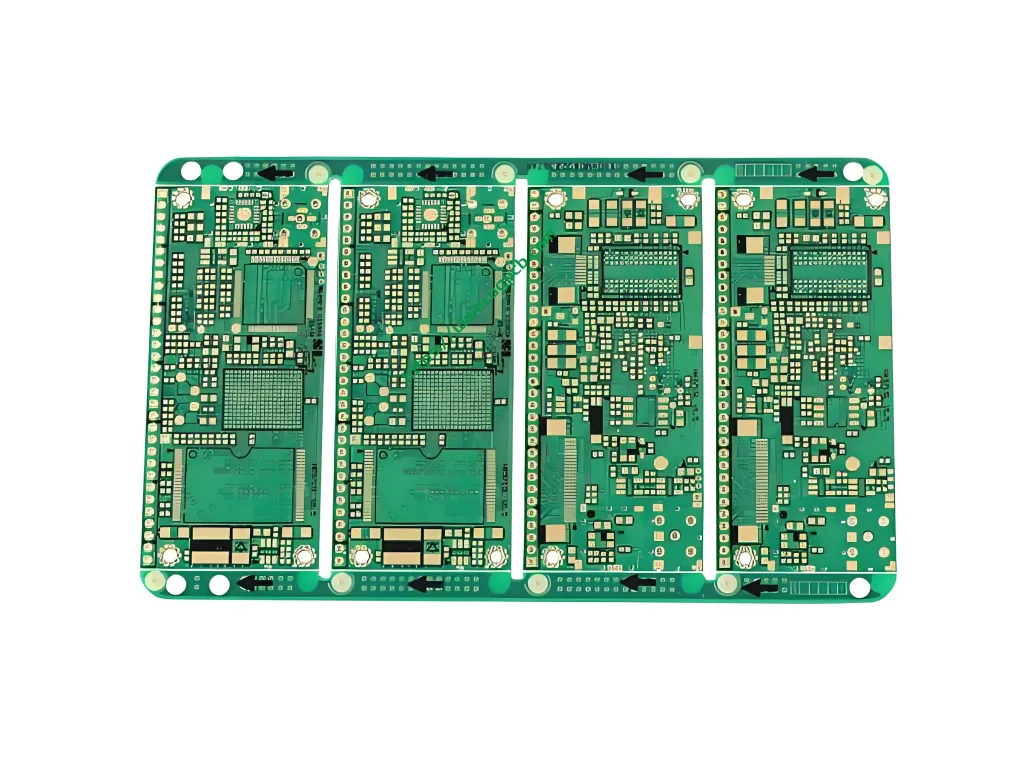

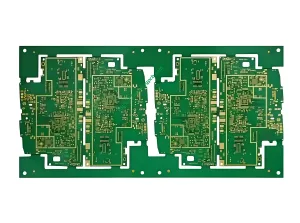

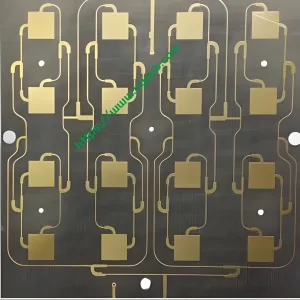

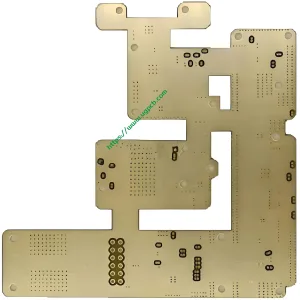

Proceso de producción

The production of the Rogers RO4350B PCB Board involves multiple precision steps. Starting with the selection of high-quality Rogers RO4350B and FR4 materials, the layers are meticulously laminated together to form a 10-layer structure. This is followed by precise drilling, recubrimiento de cobre, and etching processes to create the intricate circuitry. The final surface treatment of immersion gold enhances the board’s conductivity and corrosion resistance.

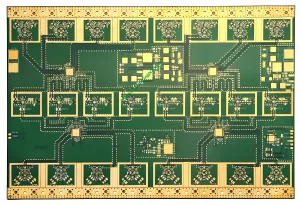

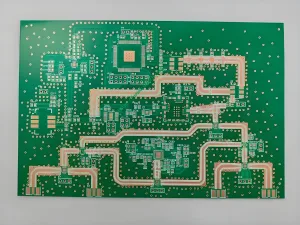

Application in Anti-Collision Systems

The Rogers RO4350B PCB Board is specifically designed for use in radio communication instruments and anti-collision systems for cars. Its superior electrical properties and thermal stability make it an ideal choice for handling high-frequency signals and ensuring reliable communication between vehicles. This helps in preventing collisions by providing accurate and timely information about the surrounding environment.

Surface Finish and Durability

The immersion gold surface treatment not only improves the electrical conductivity of the board but also enhances its durability and resistance to environmental factors. This ensures that the Rogers RO4350B PCB Board maintains optimal performance even in harsh automotive conditions.

Conclusión

The Rogers RO4350B PCB Board for Anti-Collision of Cars is a high-performance, confiable, and durable solution designed to meet the demanding requirements of advanced automotive technologies. Its unique material composition, precise production process, and superior application capabilities make it an essential component for ensuring safe and efficient vehicle communication systems.

UGPCB LOGO

UGPCB LOGO