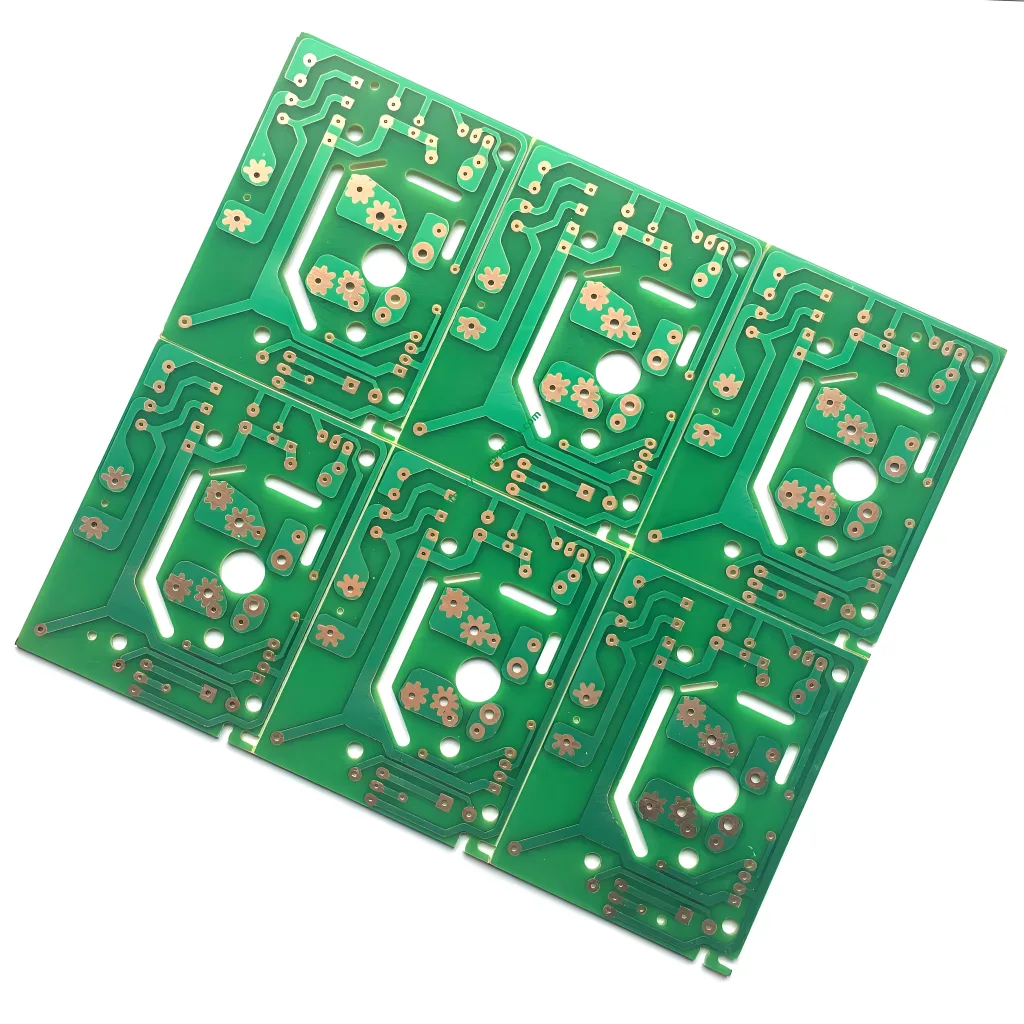

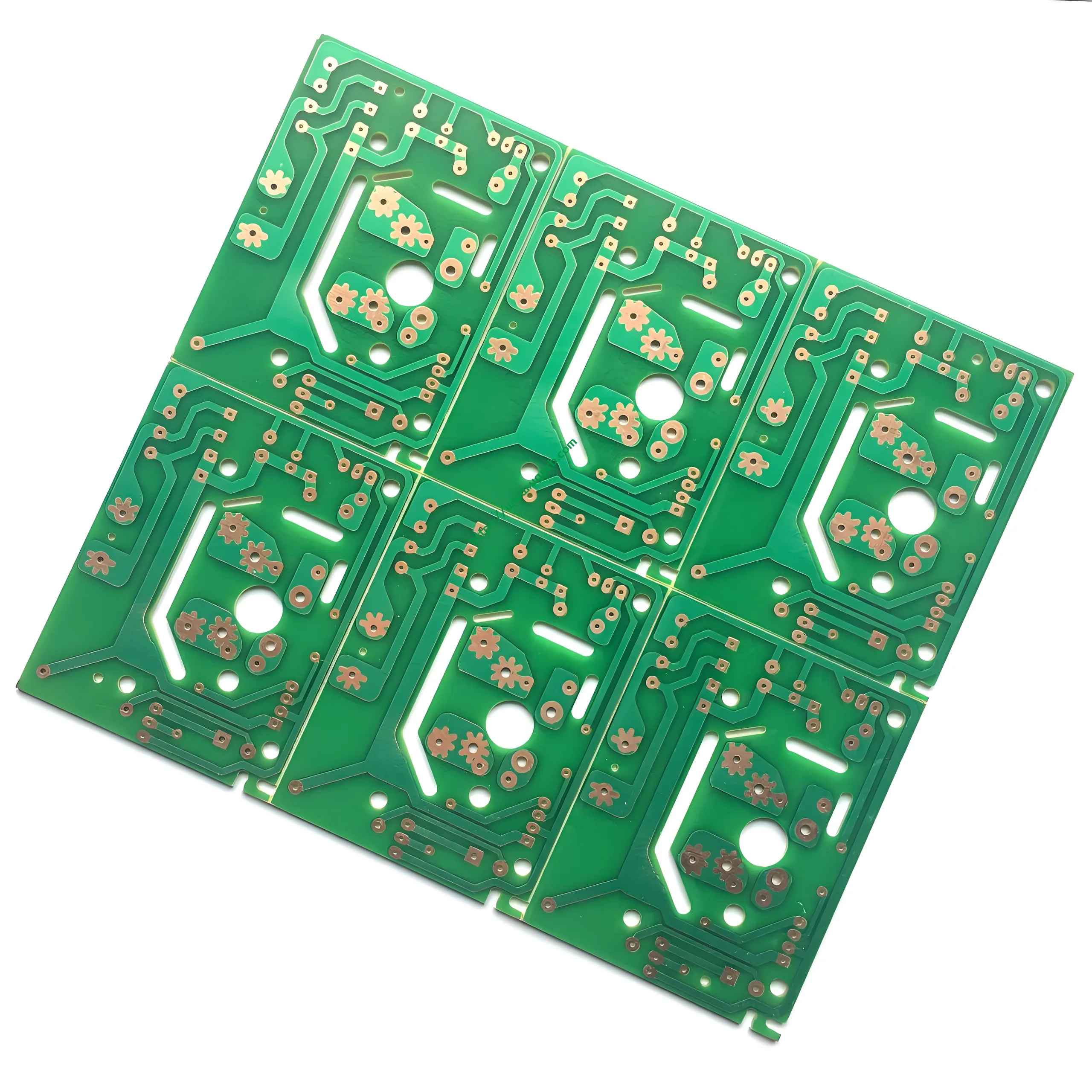

Single-sided PCB Overview

The Single-sided PCB is a fundamental component in electronic manufacturing, offering a simple yet effective platform for the assembly of electronic components. It features a single layer of conductive copper circuitry etched onto a non-conductive substrate, making it ideal for a range of applications where complexity is not a primary requirement.

Composición de materiales

The Single-sided PCB is crafted from various materials to cater to different needs:

- CEM-1: Combines paper and epoxy resin for cost-effectiveness and moderate durability.

- CEM-3: Utilizes glass fiber and epoxy resin for enhanced mechanical strength and electrical insulation.

- FR-4: Known for its flame retardant properties and high glass transition temperature, suitable for demanding applications.

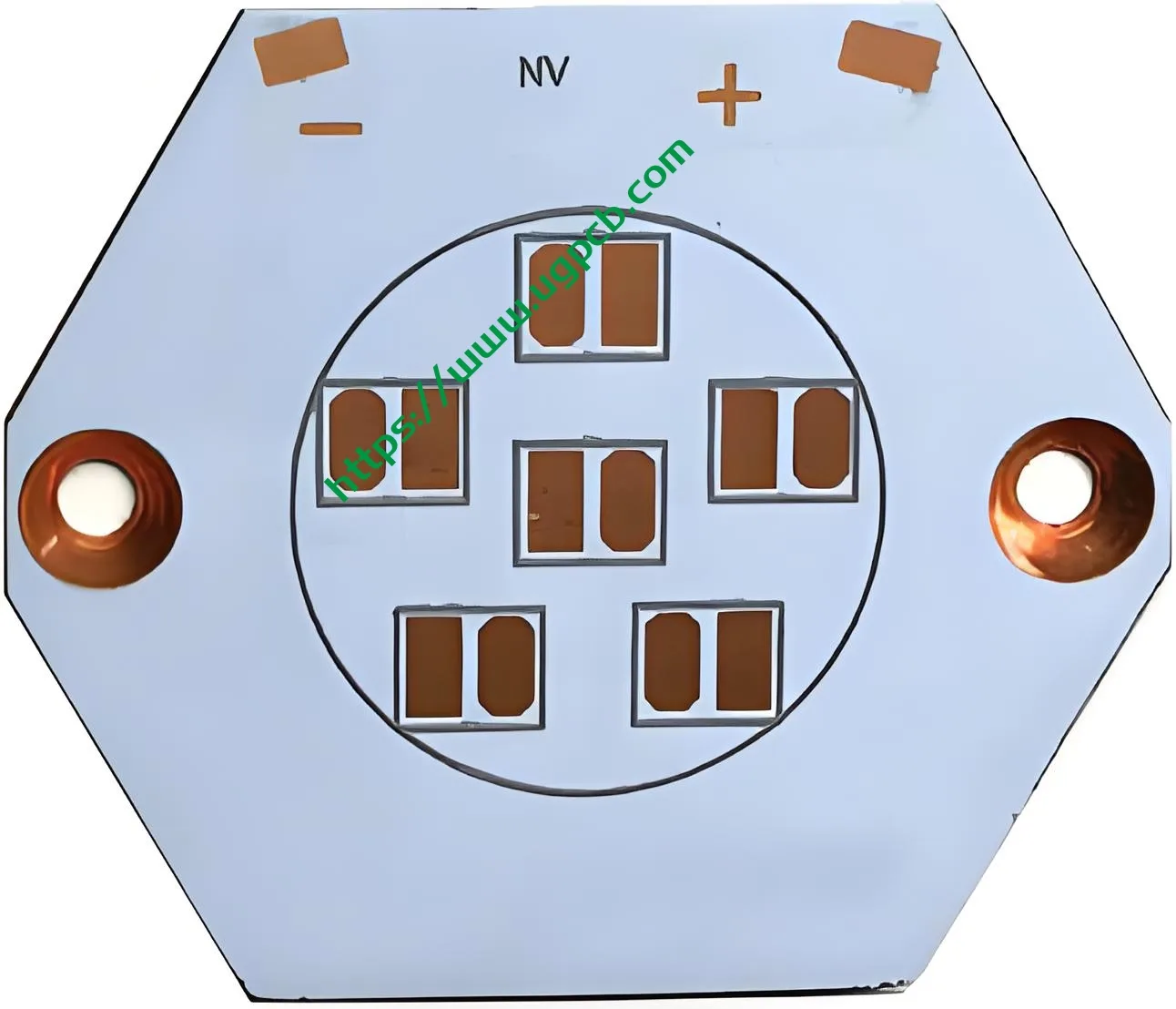

- Aluminio (Al): Offers exceptional thermal conductivity, making it ideal for heat dissipation in high-power circuits.

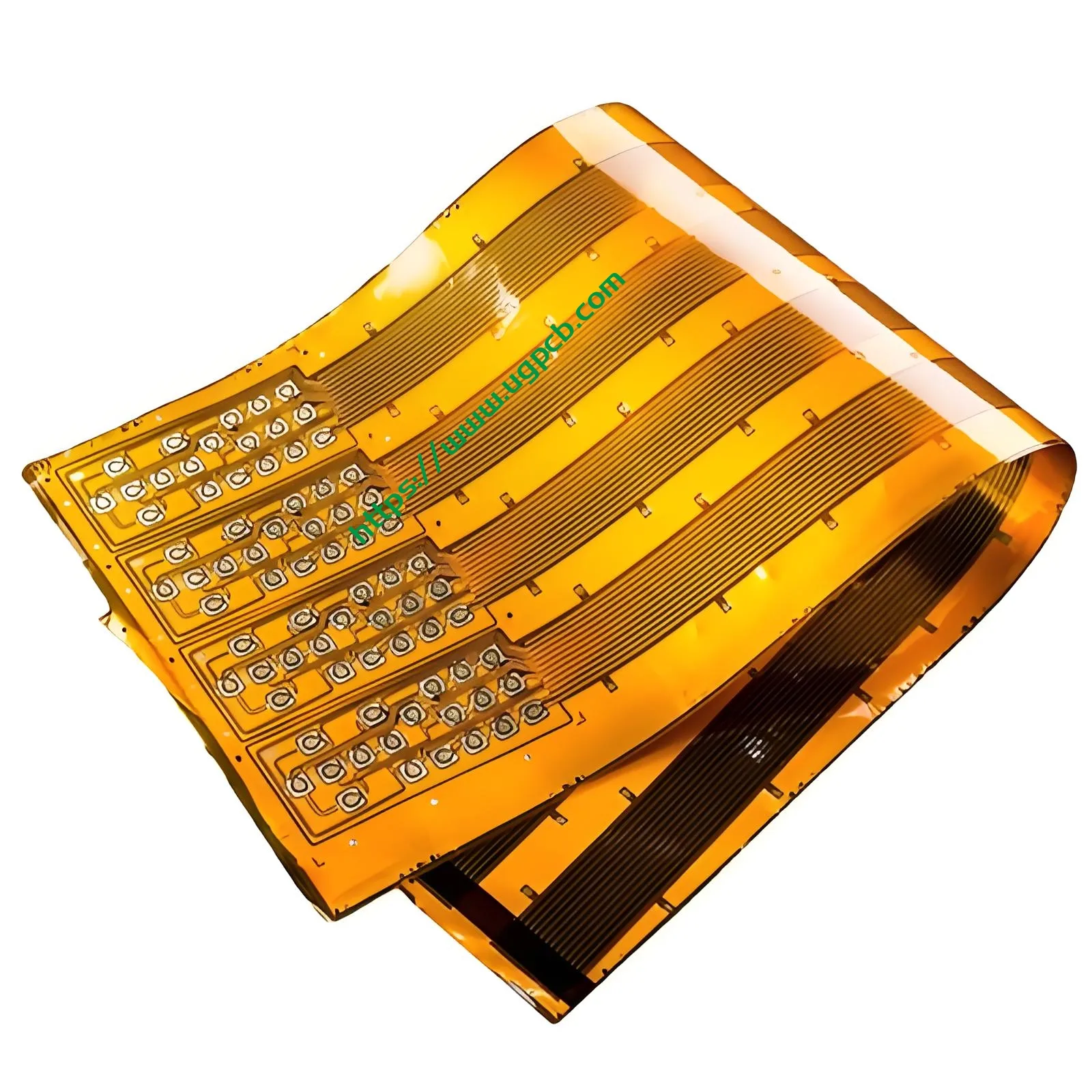

- poliimida (PI): Provides flexibility and durability, suitable for applications requiring bending or conformability.

Características de rendimiento

These boards are designed with specific performance attributes:

- Layer Configuration: 1Capa, simplifying the design and manufacturing process.

- Color Options: Available in white, negro, blue, or green, allowing for aesthetic customization.

- Espesor: Finished thickness ranges from 0.6mm to 1.6mm, accommodating various component heights and packaging requirements.

- Espesor de cobre: Copper thickness of 0.5OZ to 2OZ supports various current carrying capacities and circuit densities.

Diseño estructural

Estructuralmente, the Single-sided PCB comprises:

- Materia prima: The substrate that supports the copper circuitry.

- Lámina de cobre: Etched to form the circuit pattern.

- Acabado superficial: OSP (Organic Solderability Preservative) treatment ensures good solderability and protects the copper from oxidation.

Distinctive Features

Key features that distinguish Single-sided PCBs include:

- Min Trace/Space: Minimum trace and space of 12mil enable high-density routing, crucial for compact designs.

- Tratamiento superficial: OSP coating ensures reliable soldering and long-term circuit integrity.

- Versatilidad: Suitable for both prototype development and low-volume production runs.

Production Workflow

The production of Single-sided PCBs involves several stages:

- Design and Layout: Circuit diagrams are designed and laid out using CAD software.

- Preparación de material: The chosen substrate and copper foil are prepared.

- Circuit Etching: The copper foil is etched away to form the circuit pattern.

- Perforación: Holes are drilled for component mounting and interconnection.

- Acabado superficial: OSP coating is applied to protect the copper.

- Control de calidad: Boards undergo rigorous testing to ensure they meet specifications.

- Packaging and Shipment: Boards are packaged and shipped to customers.

Escenarios de aplicación

Single-sided PCBs are widely used in:

- Educational Kits: Simple circuits for teaching and learning electronics.

- Prototyping: Early-stage development of electronic devices.

- Low-Complexity Devices: Gadgets and appliances that do not require multi-layer complexity.

- DIY Projects: Hobbyist and maker projects requiring cost-effective and straightforward PCBs.

By understanding the material composition, performance characteristics, structural design, distinctive features, production workflow, and application scenarios of Single-sided PCBs, one can appreciate their versatility and essential role in the electronics industry.

UGPCB LOGO

UGPCB LOGO