Composición de materiales

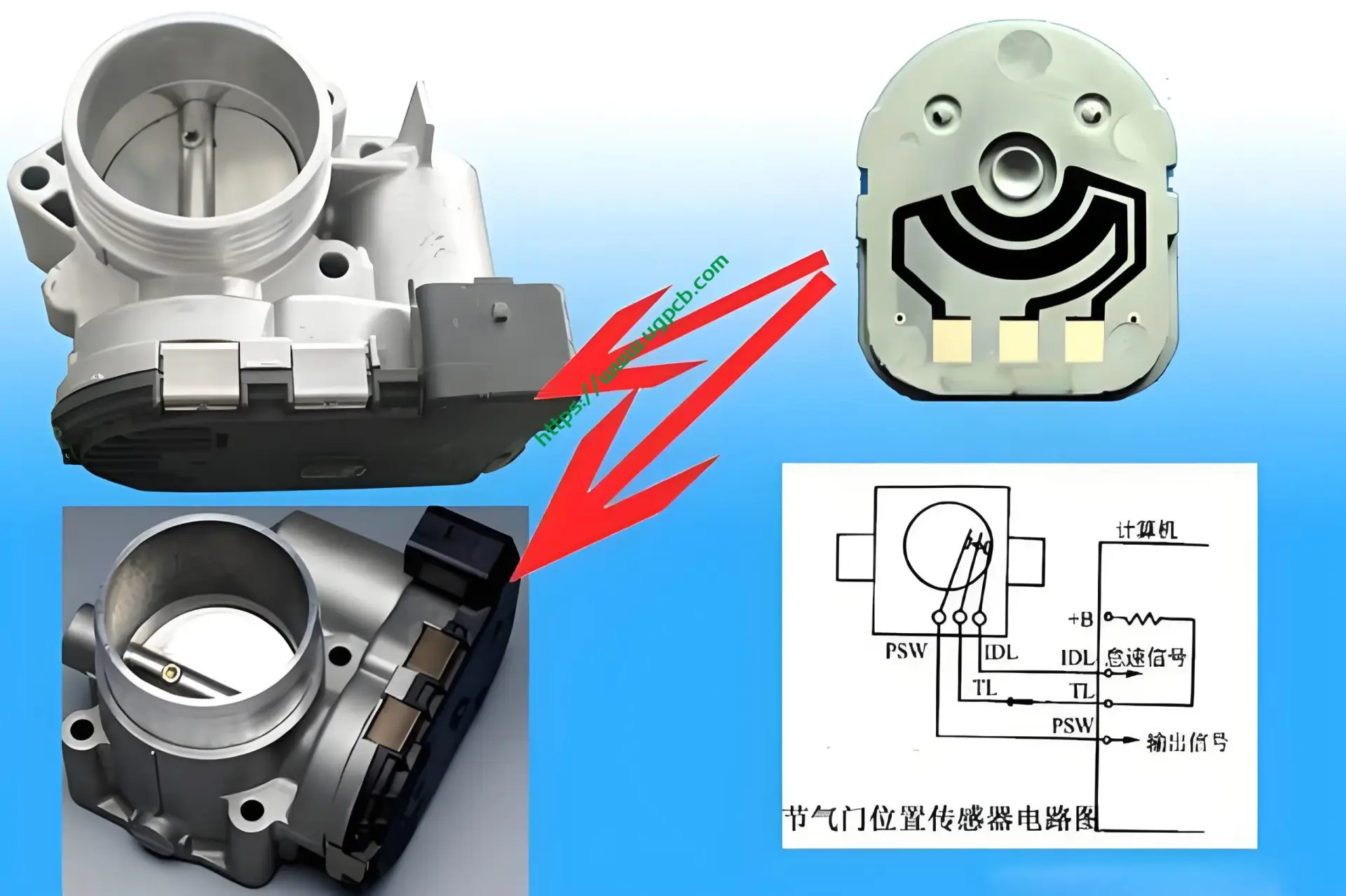

The Throttle Door Sensor PCB is crafted using high-quality ceramic PCB material. This selection ensures robustness, resistencia al calor, y aislamiento electrico, making it ideal for applications requiring reliability and durability under demanding conditions.

Performance Capabilities

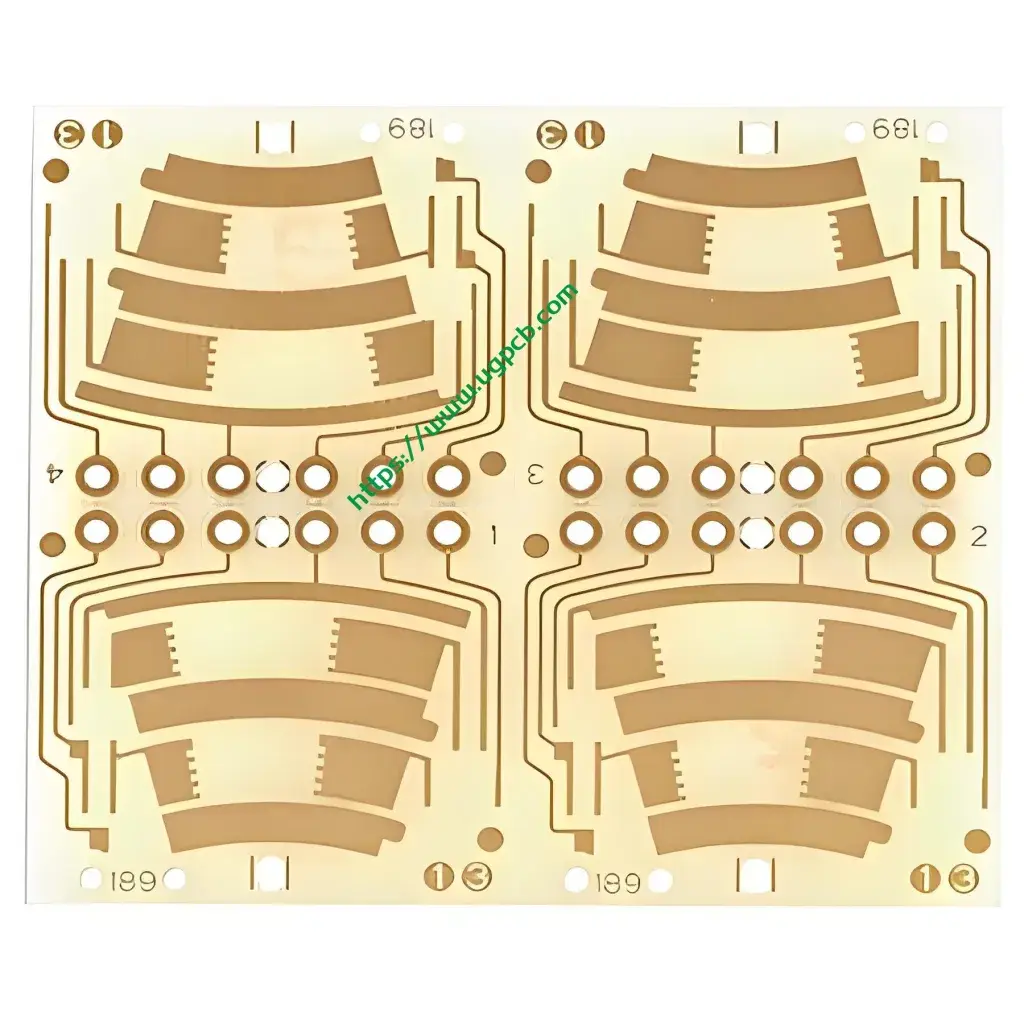

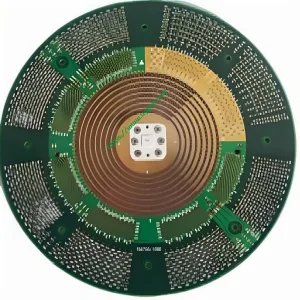

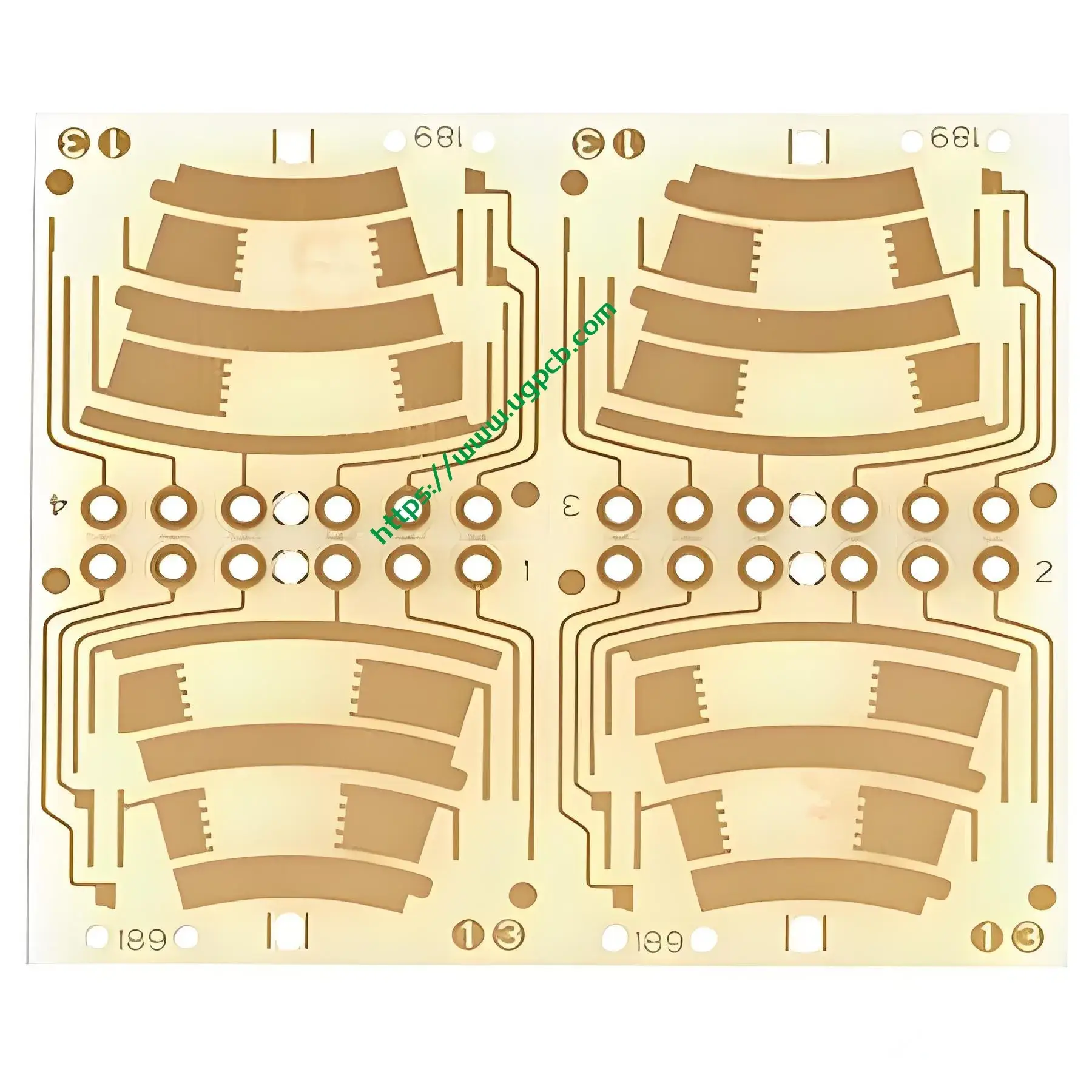

Boasting a 2-layer PCB design, the Throttle Door Sensor PCB offers superior circuit integration and compactness. The white substrate not only provides a clean aesthetic but also enhances visibility and inspection during manufacturing and maintenance. With a finished thickness of 1.6mm and a copper thickness of 1OZ, it balances strength and conductivity, ensuring efficient signal transmission and robust component mounting.

Distinctive Characteristics

The standout feature of this PCB is its special process—gold-plated PCB combined with a ceramic substrate PCB. Gold plating enhances corrosion resistance, improves electrical conductivity, and ensures smooth soldering processes, which are crucial for maintaining the sensor’s precision and longevity. The ceramic substrate further adds thermal stability, making the PCB resilient to temperature fluctuations often encountered in automotive throttle systems.

Production Workflow

The production of the Throttle Door Sensor PCB involves several meticulous steps:

- Design and Layout: Expert engineers design the PCB layout, ensuring optimal circuit placement and routing to minimize interference and maximize performance.

- Preparación de material: High-grade ceramic substrate and copper foil are prepared according to specifications.

- Manufacturing: The ceramic substrate undergoes drilling, copper etching, and layer lamination to form the 2-layer PCB structure.

- Chapado en oro: The PCB surfaces are then gold-plated to enhance conductivity and corrosion resistance.

- Control de calidad: Rigorous testing ensures that each PCB meets stringent quality standards before moving to the next stage.

- Final Assembly: Components are mounted, and the PCB is tested again in its complete form to guarantee reliability.

Escenarios de aplicación

The Throttle Door Sensor PCB is primarily used in automotive throttle systems, where precision and reliability are paramount. It serves as a critical component in throttle position sensors, enabling accurate monitoring and control of engine throttle input. By integrating seamlessly into modern vehicle electronics, it helps maintain smooth acceleration, fuel efficiency, and overall driving performance.

This advanced PCB design not only meets but exceeds the expectations for durability, exactitud, and performance in high-stress automotive environments, ensuring a safer and more enjoyable driving experience.

UGPCB LOGO

UGPCB LOGO