Introduction to Wireless Charging PCB

A Wireless Charging PCB, also known as an inductive charging circuit board, is a specialized printed circuit board designed for wireless power transfer. It enables devices such as smartphones, tabletas, and other electronic gadgets to be charged without the need for physical connectors.

Principio de trabajo

Wireless charging technology operates on the principle of electromagnetic induction. The transmitter coil generates an alternating electromagnetic field that induces a current in the receiver coil, thus transferring energy from the charger to the device.

Aplicaciones

Wireless Charging PCBs are widely used in consumer electronics for charging devices like mobile phones, smartwatches, earbuds, and even electric toothbrushes. They offer convenience, ease of use, and reduced wear and tear on charging ports.

Types of Wireless Charging PCBs

There are two main types of wireless charging technologies:

- Qi Standard: The most common and widely adopted wireless charging standard.

- PMA (Power Matters Alliance): Another popular standard, often found in older devices.

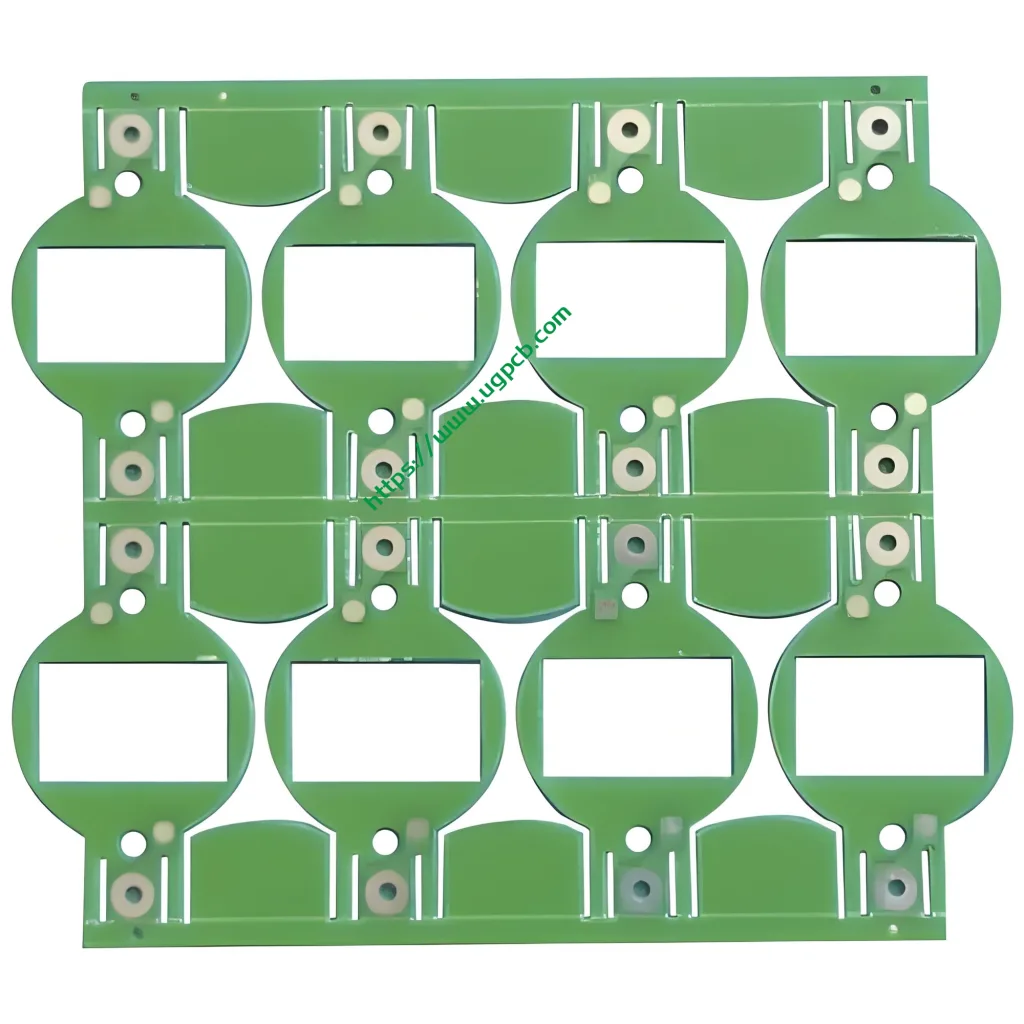

Material y construcción

- Material: S1000-2, a high-quality epoxy material.

- capas: 6 capas, providing robustness and better signal integrity.

- Color: Available in green or white.

- Espesor terminado: 1.2milímetros, ensuring durability while being slim.

- Espesor de cobre: 2ONZ, which offers good conductivity.

- Tratamiento superficial: Immersion gold with a thickness of at least 2U”, enhancing corrosion resistance and solderability.

- Copper Thickness in Hole: 35UM, ensuring strong connections.

- Apertura mínima: 0.4milímetros, allowing for fine detail work.

Características de rendimiento

Wireless Charging PCBs are designed to efficiently transfer power with minimal loss. They support fast charging capabilities and are built to withstand repeated usage over time. The immersion gold finish ensures long-lasting performance and reliability.

Características estructurales

The structure of a Wireless Charging PCB includes multiple layers of copper traces sandwiched between layers of substrate material. This multilayer design helps in managing heat dissipation and improving electrical performance. The PCB is coated with a protective layer to prevent damage and ensure longevity.

Proceso de producción

The production of a Wireless Charging PCB involves several steps:

- Diseño: Using specialized software to create the circuit layout.

- Aguafuerte: Removing excess copper to form the desired patterns.

- Laminación: Combining multiple layers together.

- Enchapado: Adding a thin layer of metal to improve connectivity.

- Inspection: Ensuring the PCB meets quality standards.

- Asamblea: Mounting components onto the PCB.

- Pruebas: Verifying functionality and performance.

Use Cases

Wireless Charging PCBs are used in various applications including:

- Electrónica de Consumo: Mobile phones, tabletas, smartwatches.

- Automotor: In-car charging systems for smartphones.

- Medical Devices: Portable medical equipment.

- Wearables: Fitness trackers, smart rings.

En conclusión, Wireless Charging PCBs represent a significant advancement in charging technology, offering convenience, eficiencia, y durabilidad. Their widespread adoption across different industries highlights their versatility and importance in modern electronic devices.

UGPCB LOGO

UGPCB LOGO