Plaqué Or: The Golden Guardian on Circuit Boards

Plaqué Or: The Golden Guardian on Circuit Boards

In the microscopic world of electronic products, chaque centimètre carré du circuit imprimé transporte d'innombrables transmissions d'informations et interactions. Parmi eux, the gold plating process and gold finger stand out as two key elements in electronic manufacturing, serving as golden bridges connecting the digital world with their unique charm and exceptional performance. Aujourd'hui, let’s uncover the mysteries of the PCB gold plating process and gold finger, exploring the stories and technical secrets behind them.

What is Gold Plating?

When we talk about gold plating, it’s important to clarify that it’s not a simple physical coating. Instead, it’s a process of forming a dense metal coating on the surface of the circuit board through chemical deposition. This layer of golden thin film acts like a guardian on the circuit board, silently protecting the stable transmission of signals and the long lifespan of the circuit.

The Necessity of Gold Plating

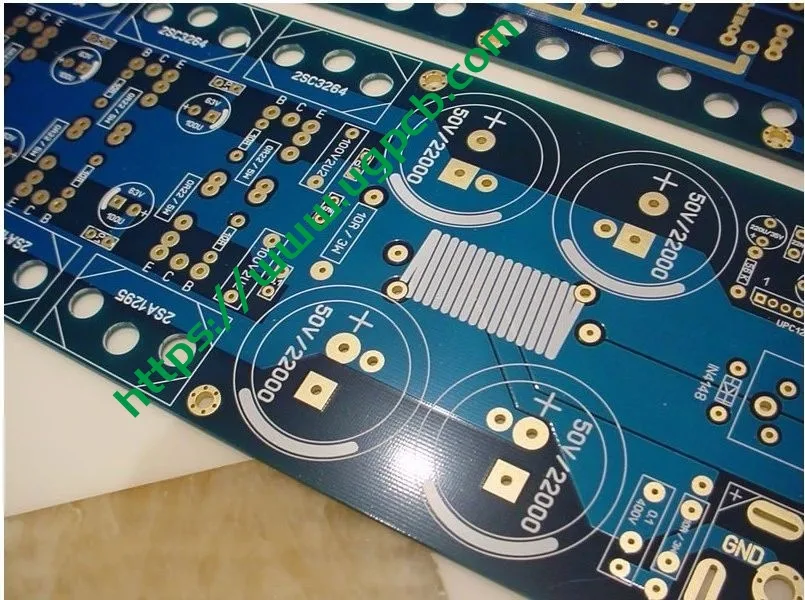

The need for gold plating stems from the copper material on the circuit board. Cuivre, especially red copper, which is the main material of circuit boards, has excellent conductivity but is highly susceptible to oxidation in the air. Oxidized copper solder joints significantly lose their conductivity, leading to issues such as poor tinning or poor contact, which seriously affects the overall performance of the circuit board. Donc, surface treatment of copper solder joints to prevent oxidation is particularly important.

The Benefits of Gold Plating

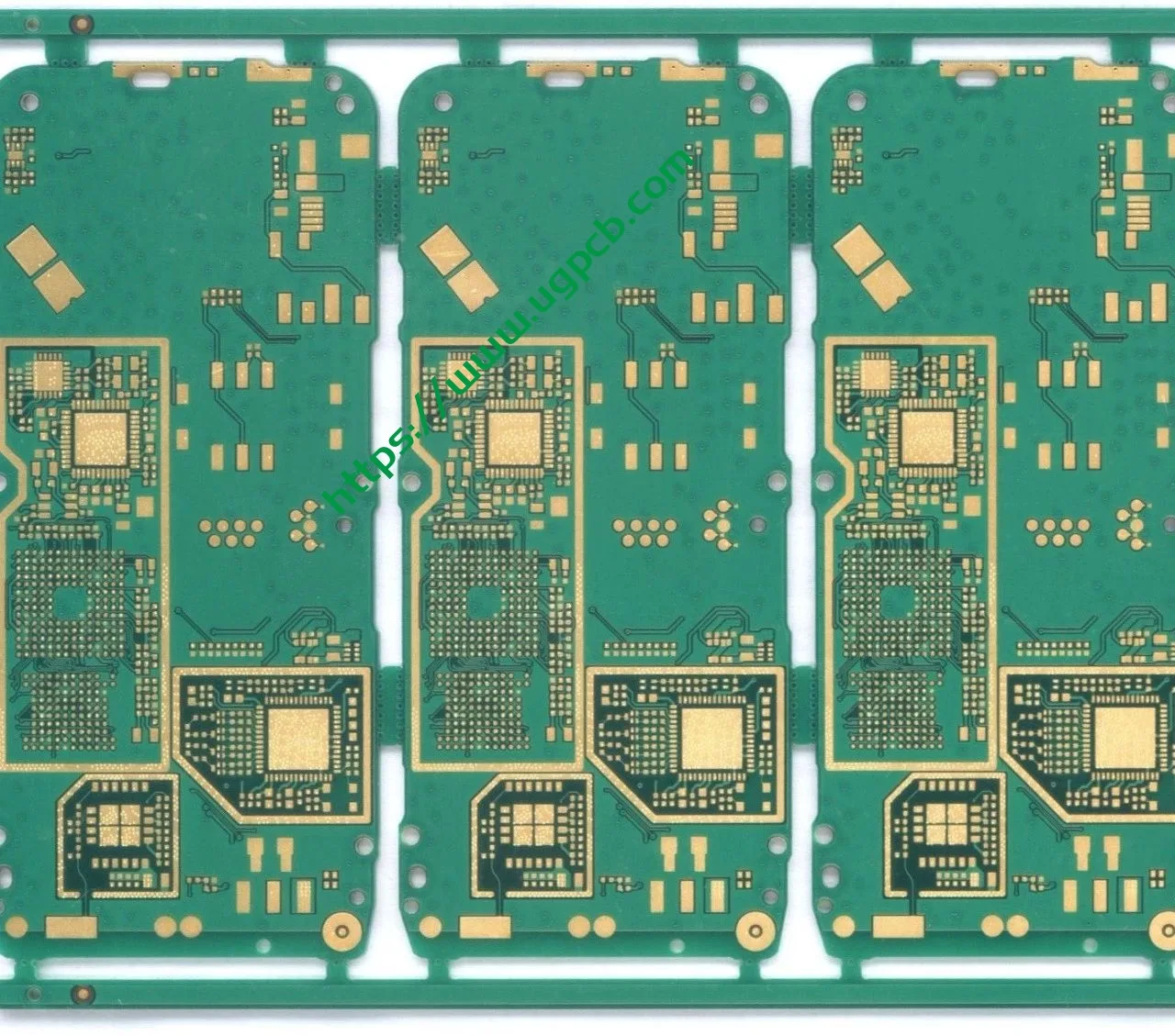

The gold plating process was born for this purpose. Through chemical reactions, a thin layer of gold is coated on the surface of copper, which not only effectively blocks the contact between copper metal and air to prevent oxidation but also enhances the overall aesthetics and welding performance of the circuit board. Gold-plated circuit boards have a bright color, good gloss, a smooth coating, and excellent weldability, providing a strong guarantee for the stable operation of electronic products.

De plus, the benefits of gold plating go beyond these. Gold has strong conductivity, good oxidation resistance, and a long service life. These properties make gold-plated boards widely used in circuit boards requiring high reliability and stability, such as keypad boards and gold finger boards. En plus, gold-plated boards have good welding performance and signal transmission performance, ensuring the stability and accuracy of signals during transmission.

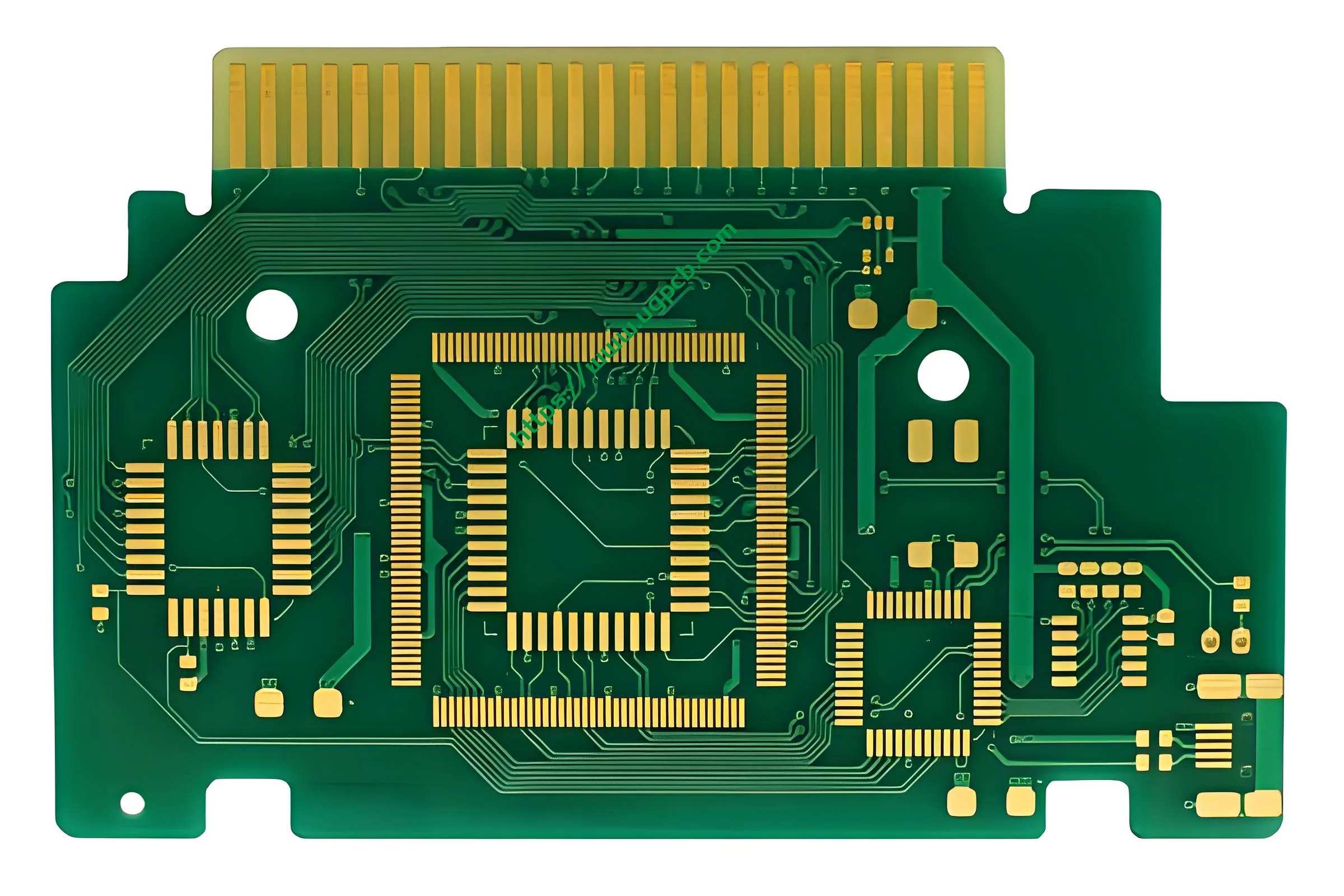

Gold Finger: The Golden Bridge Connecting the Digital World

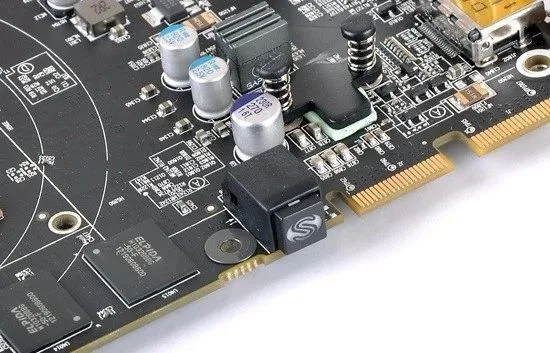

If gold plating is the golden guardian on circuit boards, then the gold finger is the golden bridge connecting the digital world. The name “gold finger” may sound mysterious, but it actually refers to the components on memory modules that connect with memory slots. These components are composed of numerous yellow conductive contacts, named for their finger-like shape and gold plating.

The existence of gold fingers ensures stable and efficient signal transmission between memory modules and memory slots. Due to gold’s extremely strong oxidation resistance and excellent conductivity, it becomes the ideal choice for gold finger plating. A layer of gold plated on the gold fingers can not only effectively prevent oxidation and corrosion but also improve signal transmission efficiency and stability.

Cependant, in the actual market, due to the high price of gold, more and more memory modules are using tin plating as an alternative to gold plating. Since the 1990s, tin materials have gradually become popular in electronic devices such as memory modules. Actuellement, the gold fingers of motherboards, mémoire, and graphics cards almost all use tin materials. Nevertheless, in some high-performance server and workstation components, gold plating is still used for gold fingers to ensure their exceptional performance and stability.

Gold Plating and Gold Finger: The Wisdom and Innovation Behind the Technology

The widespread application of the gold plating process and gold fingers not only reflects the continuous progress and innovation in electronic manufacturing technology but also demonstrates humanity’s relentless pursuit of high-quality, high-reliability electronic products. In the gold plating process, precise chemical reactions and fine coating control are used to achieve precise treatment of the circuit board surface, enhancing the overall performance and stability of the product. In the design of gold fingers, reasonable contact arrangement and coating selection ensure the accuracy and stability of signal transmission.

The wisdom and innovation behind these technologies not only show us the infinite possibilities of electronic manufacturing technology but also bring us more stable, efficient, and reliable electronic products. Whether it’s the gold plating process or gold finger technology, they are indispensable parts of the electronic world, contributing to connecting the digital world and driving technological progress.

Conclusion: The Golden Legend Continues into the Future

In the microscopic world of electronic products, the gold plating process and gold finger serve as golden bridges and guardians connecting the digital world, with their unique charm and exceptional performance making them two stars in electronic manufacturing. They not only enhance the performance and stability of electronic products but also bring us a more convenient and efficient digital life. En avant, with the continuous progress and innovation in electronic technology, the gold plating process and gold finger technology will continue to play an important role in the field of electronic manufacturing, continuing to write their golden legends.

LOGO UGPCB

LOGO UGPCB