The Technological Revolution and Market Opportunities for Automotive Antennas

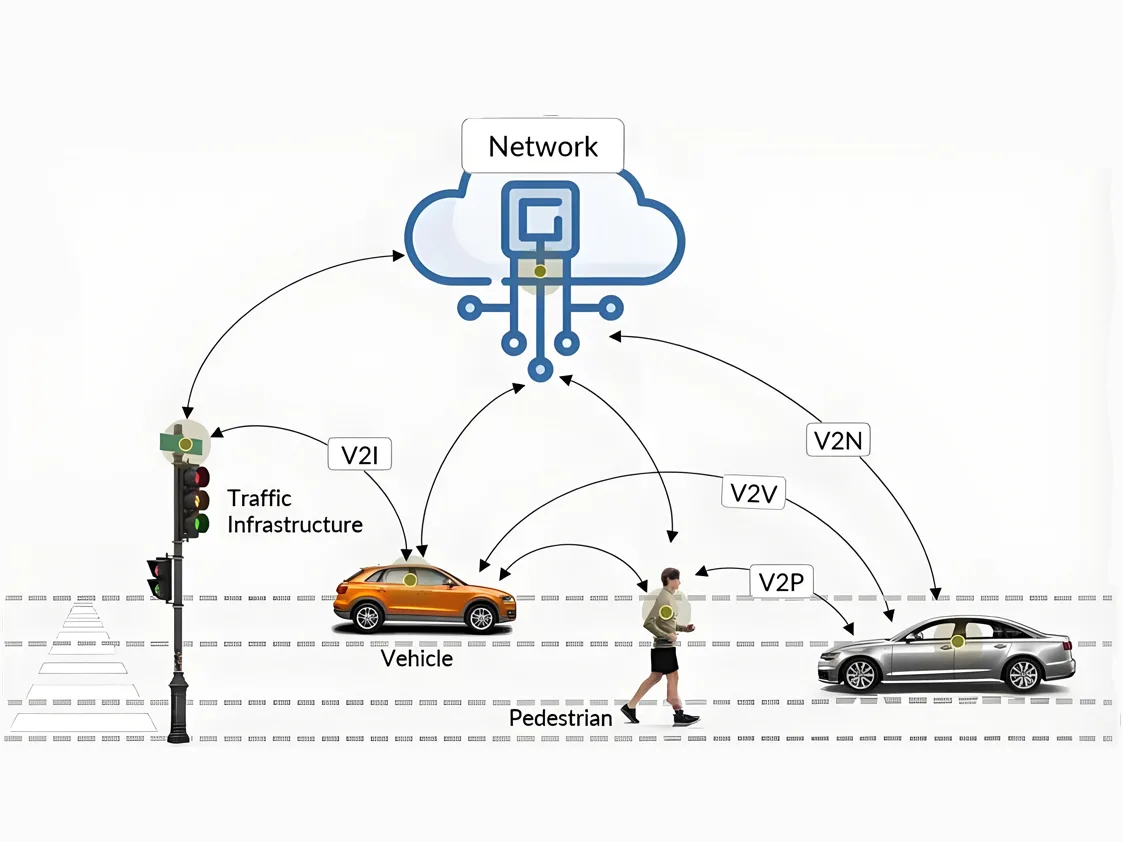

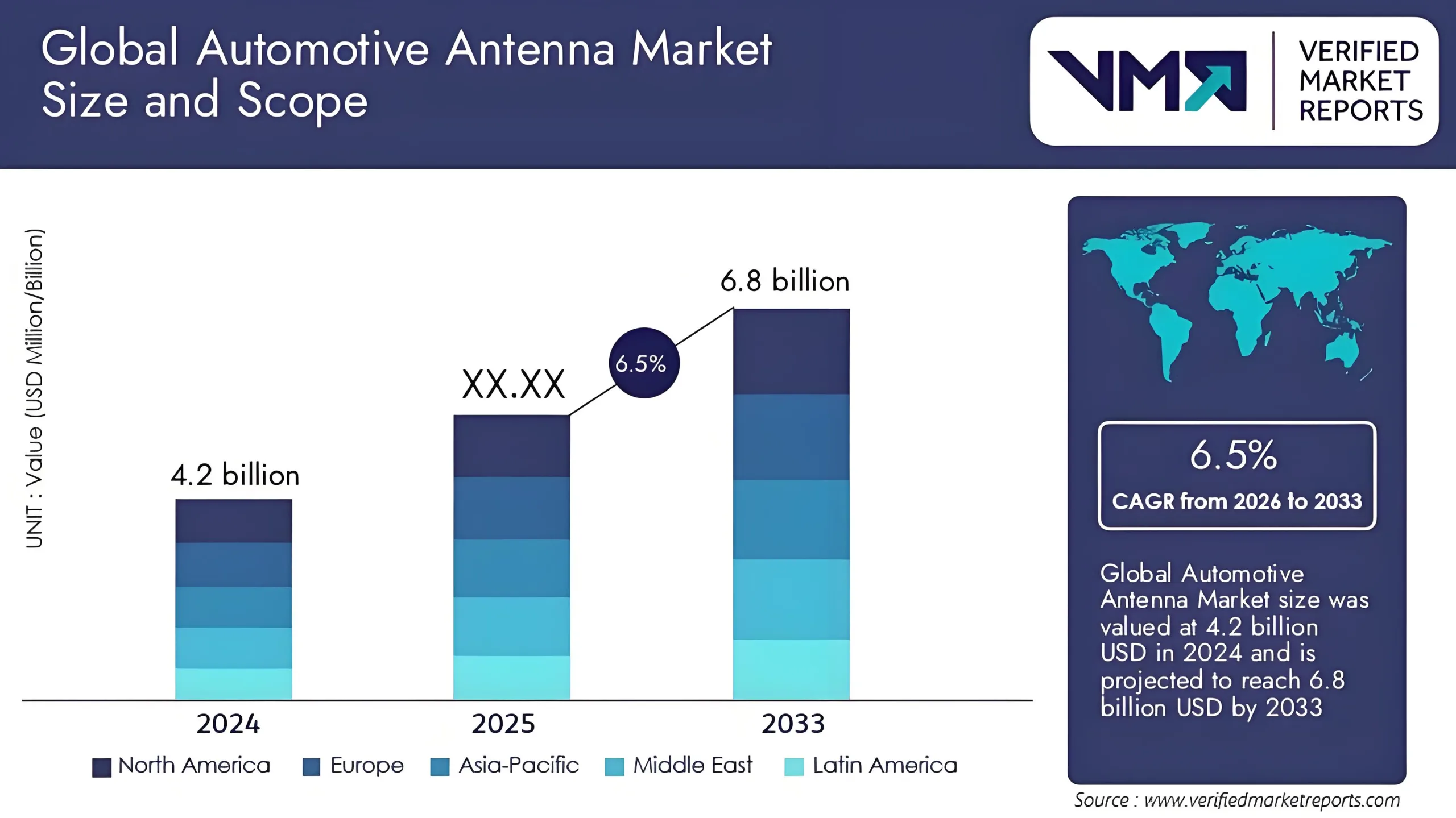

The global automotive industry is undergoing a transformative shift toward electrification, intelligence, and connectivity. According to Verified Market Reports, the automotive smart antenna market is projected to grow from 3.2billionin2022to5.6 billion by 2030, at a CAGR of 8.5%. This growth is driven by advancements in autonomous driving, 5G-V2X communication, and sensor fusion. Modern automotive antennas have evolved from basic AM/FM receivers into multifunctional systems supporting multiband communication, high-precision positioning, and ultra-low latency.

This article explores cutting-edge innovations in automotive antenna technology, critical challenges in Conception de circuits imprimés, and future trends, supported by market insights, technical principles, and engineering case studies.

Technical Categories of Automotive Antennas & PCB Integration Innovations

Miniaturization and High-Frequency Performance in Planar Antennas

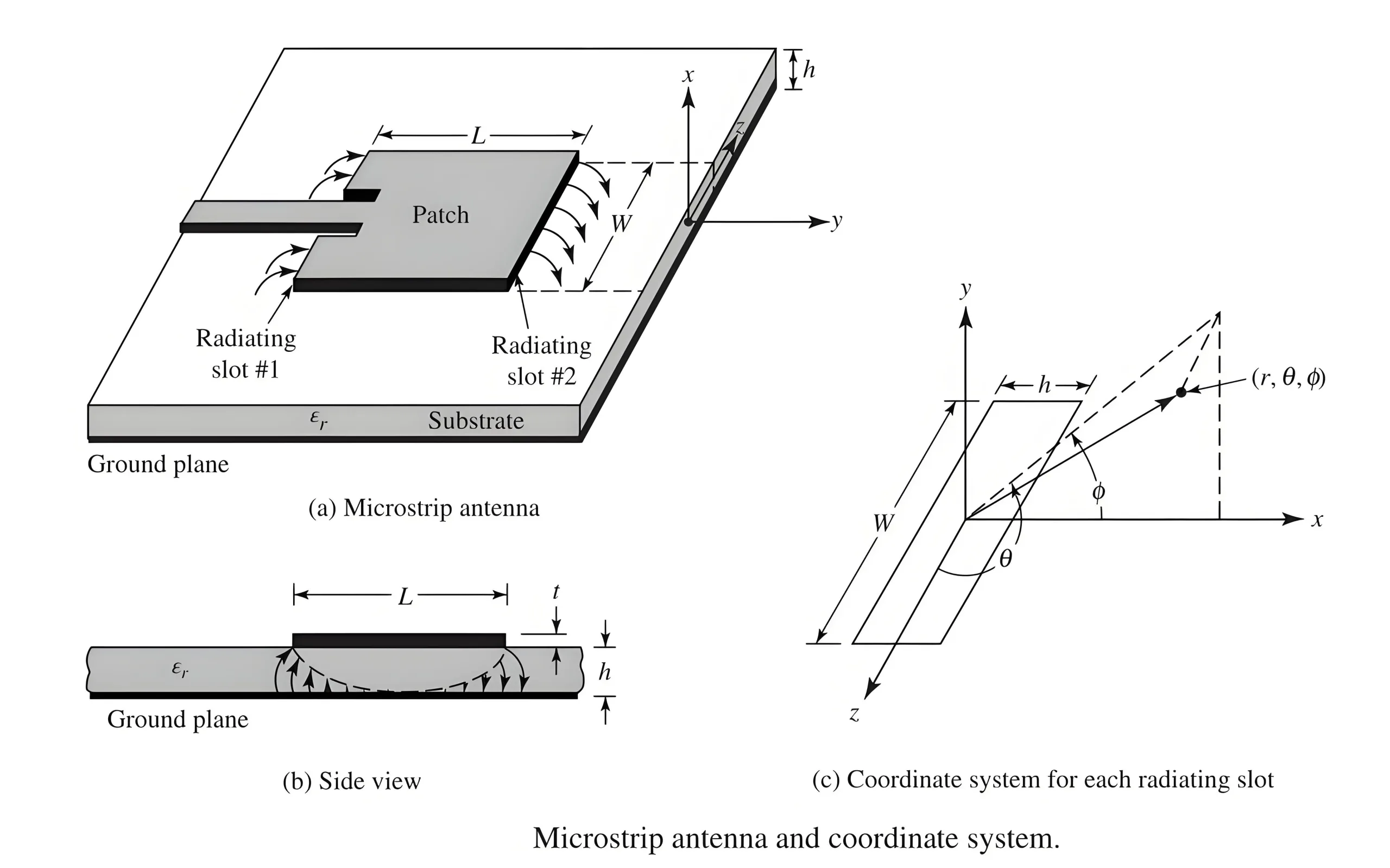

Planar antennas dominate modern vehicle designs due to their low profile and integration-friendly architecture. A typical microstrip patch antenna consists of a radiating patch, dielectric substrate, and ground plane operating across frequencies from GPS (1.575 GHz) to millimeter-wave radar (77–81 GHz).

Breakthrough Example:

- Stacked Patch Antennas: PCB multicouche stacking increases bandwidth by 15% while reducing cross-polarization interference, ideal for satellite communications and 5G-V2X.

- Ultra-Wideband (UWB) Antennas: Operating at 3.1–10.6 GHz, these enable centimeter-level positioning for keyless entry and collision avoidance systems. PCB designs require high-frequency materials like Rogers RO4350B and electromagnetic simulation for optimal patch dimensions.

Adaptive Design of Non-Planar Antennas for Complex Environments

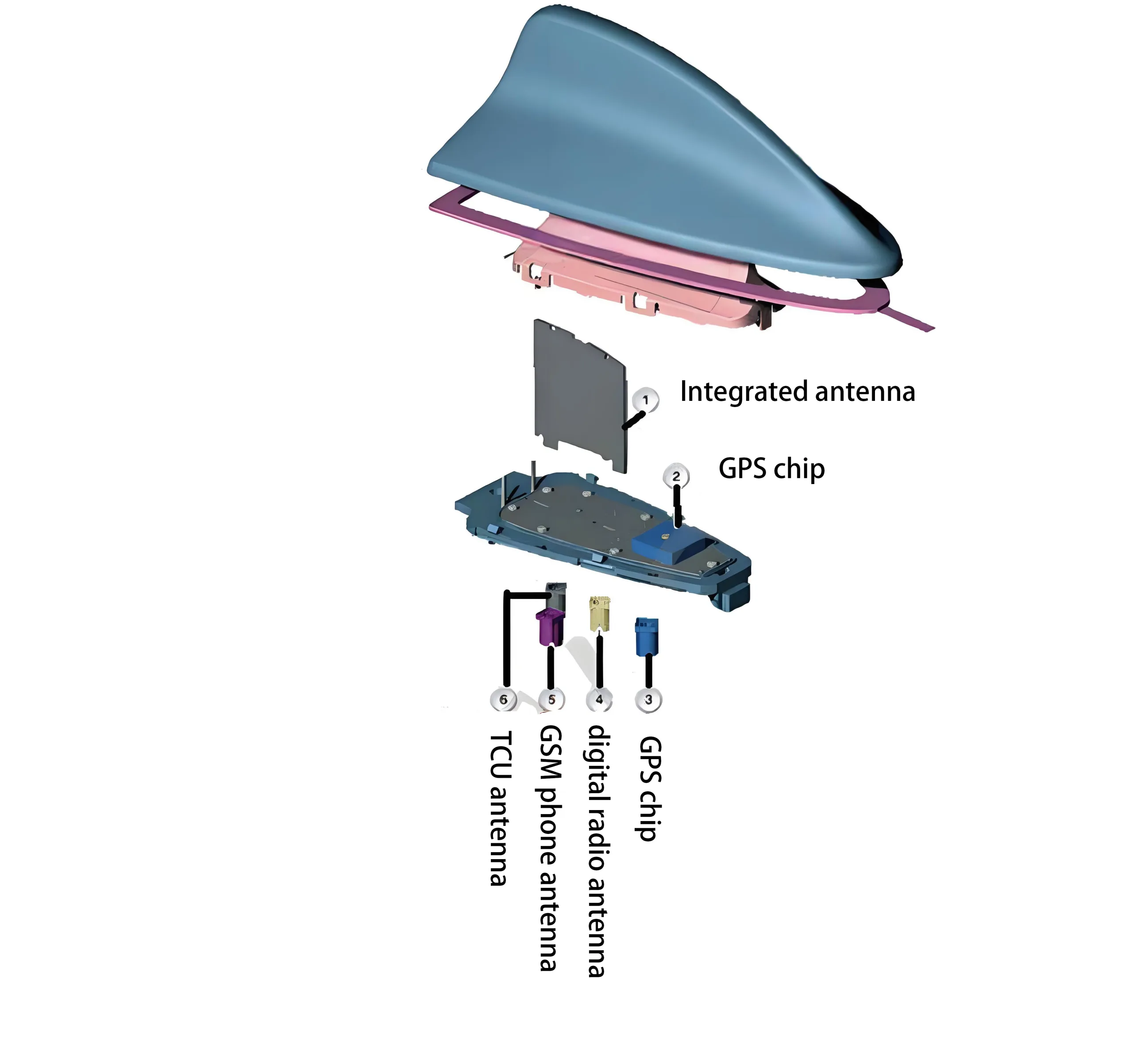

Le shark-fin antenna exemplifies non-planar design, integrating GPS, Wi-Fi, 4G/5G modules, and MIMO technology. Par exemple, a luxury vehicle model features an 8-element shark-fin antenna achieving 1 Gbps throughput via LTE 4×4 MIMO.

Engineering Challenges & Solutions:

- Mutual Coupling Reduction:

- Spatial Isolation: Vertical spacing > λ/4 (par ex., 12.7 mm at 5.9 GHz).

- Polarization Diversity: Hybrid vertical/horizontal polarization.

- Ground Optimization: Defected Ground Structures (DGS) sur PCB suppress surface waves.

Millimeter-Wave Radar Arrays: Le “Visual Cortex” of Autonomous Driving

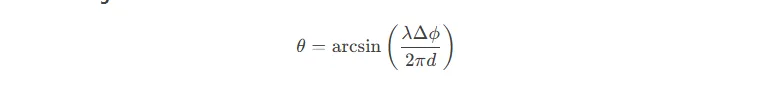

24 Ghz et 77 GHz millimeter-wave radars are pivotal for ADAS. At 77 GHz (wavelength: 3.9 mm), phased arrays enable long-range detection. A 4×4 microstrip patch array achieves ±45° beam steering with 8° beamwidth and 250-meter range.

Key PCB Requirements:

- Ultra-low-loss substrates (par ex., PTFE).

- Laser-drilled alignment for precision.

Beam Steering Formula:

Dynamic phase adjustment enables real-time beamforming for pedestrian/vehicle tracking.

Technical Challenges and Innovations in PCB Design

High-Frequency Material Selection and Processing

Millimeter-wave PCBs demand tight control of dielectric constant (Dk ±0.05) et tangente de perte (Df <0.002). Rogers RO3003 (Dk=3.0, temp. coefficient: -3 ppm/°C) is widely adopted. Plasma etching ensures transmission-line edge roughness <1 µm.

Flexible PCB Technology for Conformal Antennas

Flexible PCBs (FPCs) adapt to curved surfaces. East China Jiaotong University’s pentagram-shaped quad-band FPC antenna uses polyimide substrates (0.1 mm thickness) and FEKO simulations to achieve 2.3 dB gain at 2.4 GHz. Bend-induced impedance mismatch is mitigated via serpentine traces or gradient dielectric layers.

EMC and Thermal Management

Close antenna proximity (par ex., 30 cm between shark-fin and ADAS radar) causes interference (-15 dBm). Solutions include:

- Shielding Cavities: Metallized via arrays create Faraday cages.

- Frequency Planning: Separate 5.9 GHz comms and 77 GHz radar bands.

- Thermal Simulation: ANSYS Icepak optimizes power density distribution.

Future Trends: From Functional Components to Intelligent Nodes

5G-V2X and AI-Driven Dynamic Reconfiguration

Post-2025, 5G-V2X will deliver 20 Gbps speeds and 1 ms latency. Dynamically Reconfigurable Antennas (DRAs) using PIN diodes or MEMS switches enable automatic frequency band switching (par ex., 700 MHz in tunnels).

Material Revolution: Metasurfaces and Photonic Crystals

Metamaterial Antennas with negative refractive indices shrink sizes to λ/10. Yokowo’s Metamaterial-on-PCB antenna achieves 5 dBi gain at 2.4 GHz with 1.2 mm thickness. Photonic crystal substrates suppress surface waves, boosting efficiency to >85%.

Modular PCB Design and OTA Upgrades

Tesla’s patented “Antenna Matrix” supports OTA beam pattern updates. AI-driven beam steering optimizes V2I communication, enabled by HDI PCBs with 30/30 μm line/space.

Conclusion: Industry Transformation Through Technological Convergence

PwC predicts 55% of new vehicles will be electric by 2030, avec 40% of miles driven autonomously. Automotive antennas are evolving into intelligent nodes within smart transportation networks. Success in this $1 trillion market hinges on breakthroughs in miniaturization, energy efficiency, and multidisciplinary collaboration between PCB designers, RF engineers, and material scientists.

This article explores cutting-edge innovations in automotive antenna technology, critical challenges in PCB design, and future trends, supported by market insights, technical principles, and engineering case studies.

LOGO UGPCB

LOGO UGPCB