Substrat en verre: Un moteur puissant qui remodèle le paysage de l’industrie des PCB

Dans la carte de circuit imprimé (PCB) industrie, Les substrats en verre modifient tranquillement le paysage avec une présence sans précédent. Ce ne sont pas seulement le matériau de base de l'emballage de puces de nouvelle génération, mais aussi une force cruciale stimulant le développement de l'informatique haute performance, conduite autonome, L'Internet des objets (IdO), et d'autres domaines. Cet article vous emmènera dans un voyage approfondi dans la définition, rôle, avantages, chaîne industrielle, perspectives de marché, et paysage concurrentiel de substrats en verre, révéler comment ce géant de l'industrie mène la nouvelle transformation de l'industrie des PCB.

je. Définition et rôle des substrats de verre

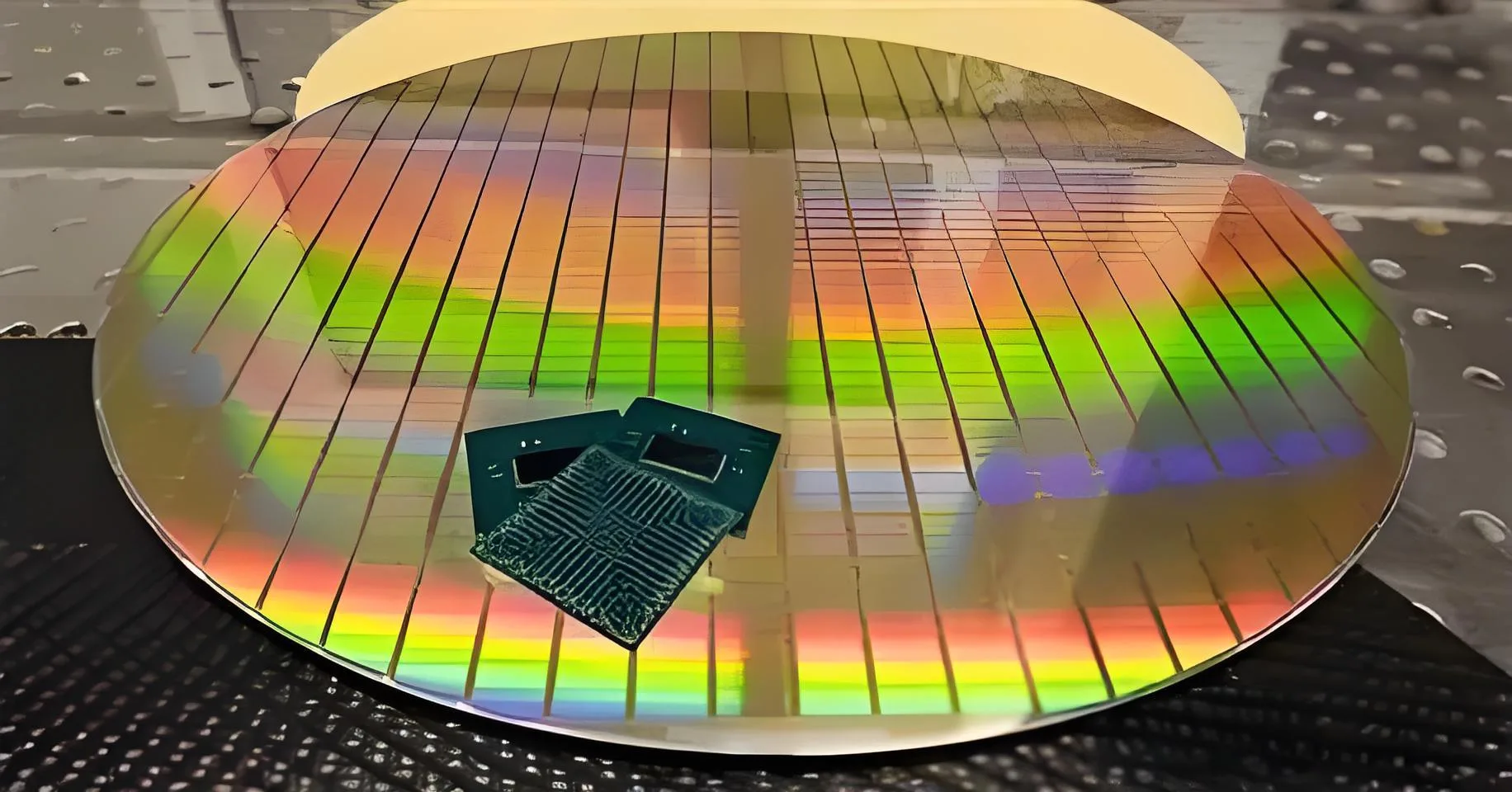

Substrats de verre, Comme son nom l'indique, sont des substrats de puce en verre. En tant que dernier protagoniste de l'emballage de puces, Ils portent des décès de puces, Assurer la stabilité de la structure de la puce tout en transmettant les signaux de la folie au package. Les substrats en verre sont devenus un choix idéal pour créer un emballage de puces haute performance en raison de leur stabilité mécanique exceptionnelle et de leur densité d'interconnexion plus élevée.

Substrat en verre

Dans le domaine des matériaux de composants électroniques, Les substrats en verre démontrent un immense potentiel. Ils fournissent non seulement une planéité ultra-bas, Réduire la distorsion du modèle et améliorer la profondeur de mise au point de la photolithographie, mais aussi à atteindre une densité d'interconnexion plus élevée, Ce qui est crucial pour la transmission de puissance et le routage des signaux dans l'emballage de nouvelle génération. En plus, La stabilité thermique et mécanique des substrats en verre leur permet de gérer plus efficacement les températures plus élevées tout en gérant efficacement la dissipation thermique des puces haute performance.

II. Avantages uniques des substrats en verre

La raison pour laquelle les substrats de verre se distinguent dans l'industrie du PCB résident dans leurs propriétés physicochimiques uniques.

1.Stabilité thermique élevée

Le composant principal du verre est le dioxyde de silicium, qui est plus stable à des températures élevées. Il peut gérer efficacement la dissipation thermique des puces haute performance, prolongeant ainsi la durée de vie de l'équipement.

2.Densité d'interconnexion élevée

Les substrats en verre peuvent atteindre une densité d'interconnexion plus élevée, Amélioration significative de la connectivité des transistors dans l'emballage des puces. Par exemple, Le nombre de trous sur un substrat en verre est beaucoup plus grand que sur les matériaux organiques de la même zone, et l'espacement entre le verre via des trous peut être inférieur 100 micromètres, augmentant directement la densité d'interconnexion par 10 fois.

3.Faible distorsion de motif

Les substrats en verre peuvent réduire la distorsion du motif en 50%, Améliorer la profondeur de mise au point de la photolithographie, et assurer une fabrication plus précise et précise de semi-conducteurs.

4.Planéité forte

Le verre est plus facile à aplatir, Rendre les emballages et la photolithographie plus simples, ce qui est crucial pour le système de nouvelle génération en package (Siroter) technologie.

III. Chaîne industrielle et perspectives de marché des substrats de verre

L'en amont de la chaîne de l'industrie du substrat de verre se concentre sur la fabrication de matériaux, y compris des liens clés tels que la fabrication du substrat de verre, filtres optiques, polariseurs, et modules de rétroéclairage. En raison de barrières techniques élevées, Ces liens sont monopolisés par quelques joueurs, Profiter de parts de marché élevés et de marges bénéficiaires.

Les principales méthodes de production pour les substrats en verre sont le processus flottant, Processus de débordement de débordement, et le processus de tirage à la baisse. Plus que 99% de l'approvisionnement mondial sur le substrat en verre TFT-LCD est concentré dans quelques fabricants comme Corning aux États-Unis et Asahi Glass au Japon. Cependant, avec le développement de marchés émergents, Les entreprises nationales telles que Tongxu Optoelectronic et Rainbow Affichage accélèrent la substitution des importations, Augmenter progressivement leurs parts de marché.

Les perspectives du marché pour les substrats en verre.

Concernant les perspectives du marché, Le marché mondial du substrat d'emballage IC est rapidement en expansion et devrait atteindre une taille de $315.4 milliards dans 2029. Avec le développement rapide des serveurs, 5G, intelligence artificielle, big data, IdO, conduite intelligente, et d'autres domaines, La demande de puces continue de croître. Comme le matériau de base, Les substrats d'emballage IC sont devenus le segment la plus rapide de l'industrie des PCB. Substrats de verre, En tant que dernière tendance des substrats d'emballage IC, devraient avoir un taux de pénétration de plus 50% dans les cinq ans.

La taille du marché de l'industrie du substrat de verre en Chine, Offrir de larges perspectives de marché. Selon les données de la Chine de commerce China pour l'importation et l'exportation de machines et de produits électroniques, La taille du marché des substrats en verre en Chine était approximativement RMB 31 milliards dans 2022 et atteint RMB 33.3 milliards dans 2023. Avec la vulgarisation et la mise à niveau de produits électroniques tels que les smartphones, comprimés, et les téléviseurs, La demande de dispositifs d'affichage en cristal liquide augmente en continu, stimuler la croissance du marché du substrat de verre.

IV. Paysage compétitif de substrats en verre

L'industrie du substrat de verre est la technologie et le capital, avec des barrières élevées, concurrence intense, et une concentration élevée. Le marché mondial est principalement monopolisé par les entreprises américaines et japonaises, comme Corning et Asahi Glass, qui ont des avantages techniques importants. Cependant, avec la montée des entreprises nationales, Le paysage concurrentiel change.

Le paysage concurrentiel de l'industrie du substrat de verre en Chine est stable mais dominé par les entreprises étrangères. Dans 2022, Les entreprises étrangères comptaient plus que 70% de la part de marché dans l'industrie du substrat de verre en Chine. Cependant, avec l'influence croissante de la Chine dans l'industrie du panel et les percées technologiques continues par les fabricants nationaux, La localisation des substrats en verre accélère. Par exemple, La première ligne de production de substrat de verre TFT-LCD en verre de 8,5e génération en Chine a été enflammée avec succès, Marquant la première fois que la Chine a atteint la localisation des substrats en verre flottant ultra-minces TFT-LCD de 8,5e génération.

V. Substrats de verre: Un puissant moteur de l'industrie des PCB

Avec leurs avantages uniques, Les substrats en verre deviennent un “puissant” moteur de l'industrie des PCB. Ils entraînent non seulement le développement d'un informatiation haute performance, conduite autonome, IdO, et d'autres champs mais dirigent également la révolution de la technologie d'affichage. Dans la technologie d'affichage LED, Les substrats en verre servent de composants clés, Fournir une plate-forme physique stable et d'excellentes performances optiques, permettant une résolution plus élevée et une qualité d'image plus fine.

Avec innovation technologique continue et réduction des coûts, Les perspectives de demande des substrats de verre deviendront plus larges. À l'avenir, Nous pouvons nous attendre à voir des produits d'affichage plus innovants en utilisant des substrats en verre, apporter des changements révolutionnaires à notre expérience visuelle.

Conclusion: Substrats de verre, Une force puissante remodelant le paysage de l'industrie

Substrats de verre, le “puissant” Conducteur dans l'industrie PCB, remodeler le paysage de l'industrie avec leur charme unique et leur potentiel illimité. De la définition et du rôle aux avantages, chaîne industrielle, perspectives de marché, et paysage compétitif, Les substrats en verre démontrent leurs qualités remarquables. Allons-nous avec avec impatience comment cela “puissant” Le conducteur mènera l'industrie des PCB vers un avenir plus glorieux.

LOGO UGPCB

LOGO UGPCB

Je partage complètement votre opinion. Je pensais excellent, C'est d'accord avec toi.

Bravo, Cette phrase a eu juste au fait