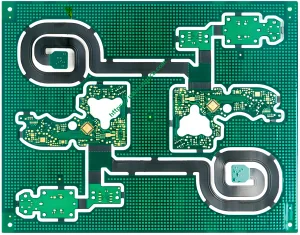

PCB rigide-flexible

Introduction to Rigid-Flex PCB

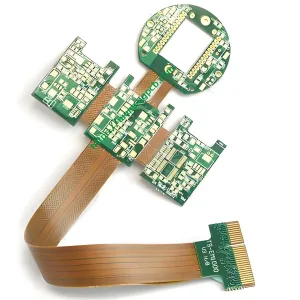

Rigid-Flex PCB combines flexible PCB (FPC) and rigid PCB technologies. It integrates FPC’s flexibility with PCB’s structural integrity through processes like pressing, creating a hybrid circuit board tailored for complex applications.

Processus de production

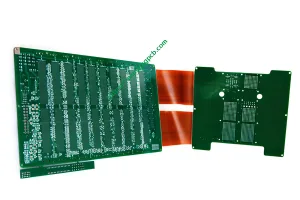

Manufacturing Rigid-Flex PCBs requires both FPC and PCB production equipment. The workflow involves:

- Conception: Engineers draft circuit layouts and shapes.

- Fabrication: FPC and PCB layers are produced separately.

- Assemblée: Layers are pressed together seamlessly.

- Contrôle de qualité: Rigorous inspection precedes shipment to ensure reliability.

Definition and Core Characteristics

A Rigid-Flex PCB merges flexible and rigid circuit boards into a single structure, leveraging FPC’s bendability and PCB’s durability. This fusion enables adaptability to irregular shapes and high-stress environments.

Avantages clés

-

Durability in Harsh Conditions

Resists impact and vibration, ensuring stable performance in demanding settings.

-

High-Precision Reliability

Reduces failure risks in critical systems where connectors or cables might falter.

-

Space Efficiency

Eliminates bulky connectors, optimizing component density.

-

Cost-Effective Integration

Replaces multiple rigid PCBs with a single streamlined solution.

Primary Applications

-

Industrial and Medical Equipment

Precision instruments requiring accuracy, sécurité, and soil resistance.

-

Automotive Systems

Steering wheel controls, infotainment screens, capteurs, and navigation modules.

-

Electronique grand public

Advanced features in digital cameras (DSCs) and camcorders (DVs).

-

Mobile Devices

Hinge mechanisms, camera modules, and RF components in foldable phones.

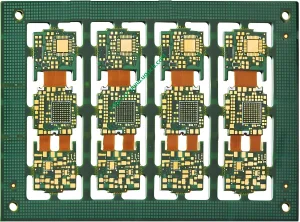

Prototype Laminate Process Considerations

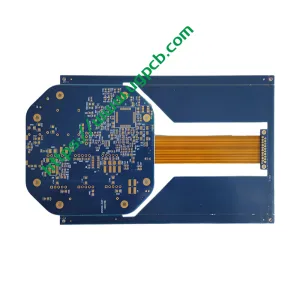

- Alignment: Precision in pre-lamination processing minimizes layer misalignment.

- Material Stress: Consistent glass cloth orientation and thermal stress relief prevent warping.

- Rigid Board Thickness: Optimal thickness (0.8–1.0mm) balances stability and economy.

- Flexible Window Milling: Laser cutting ensures clean edges without compromising structural integrity.

Manufacturing Workflow

-

Sélection des matériaux

-

Key Process Controls

- Inner layer graphic transfer

- Multi-layer flexible material alignment

- Stratification, forage, and corrosion control

- Electroplating and solder mask application

-

Final Shaping

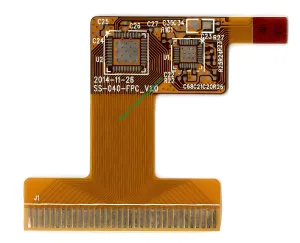

Design Guidelines

-

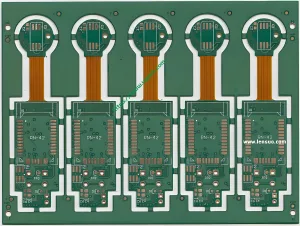

FPC Layer Placement

Prioritize inner layers for 8–10 layer boards (par ex., 4/5th layer in 8-layer stacks).

-

Bending Clearance

Maintain ≥1mm gaps between rigid and flex zones; ≥0.8mm between branch flex segments.

-

Wiring Principles

- Stagger adjacent layer traces to enhance flex life.

- Use arc transitions (≥0.5mm radius) at rigid-flex junctions.

- Avoid vias in flex zones; opt for grid copper in non-impedance-controlled signals.

-

Placement des composants

Keep devices ≥1mm from flex zones; use arc routing for flex-zone traces.

Rigid-Flex PCB Stackup Example

A 4-layer stackup demonstrates layer prioritization for flex integration, balancing signal integrity and mechanical stress.

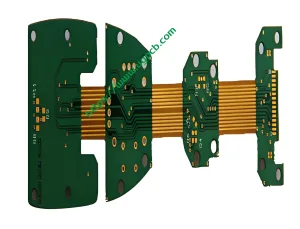

Adapters and Applications

Rigid-Flex adapters facilitate testing and structural modifications in industries like automotive, médical, et électronique grand public.

Cost Considerations

Higher production costs stem from material differences (thermal expansion, adhesion). Suppliers like UGPCB offer competitive pricing and end-to-end assembly services.

LOGO UGPCB

LOGO UGPCB

WeChat

Scannez le code QR avec WeChat