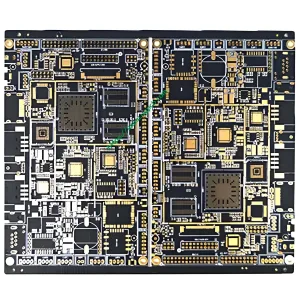

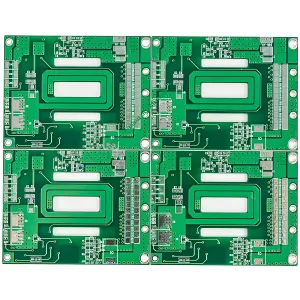

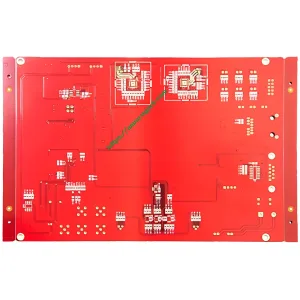

Carte PCB standard

Introduction: Standard PCB Boards – The Foundation of Electronics Manufacturing

As the core component of electronic devices, Standard PCB Boards (Standard Printed Circuit Boards) are widely adopted in industrial control, électronique grand public, and communication equipment due to their mature technology and versatility. Leveraging over a decade of industry expertise, UGPCB delivers end-to-end Standard PCB solutions—from rapid prototyping to mass production—supported by fully automated production lines, UL/ISO certifications, and a global delivery network.

1. Core Specifications & Technical Advantages of UGPCB Standard PCBs

1.1 Comprehensive Parameter Coverage

- Layer Options: Simple face, double face, 4-6 layer multilayer PCBs

- Matériels: FR-4 standard/halogen-free boards, aluminum substrates, high-frequency materials (RO4350B)

- Épaisseur du cuivre: 1/2OZ to 6OZ (customizable for heavy copper power boards)

- Trace Width/Spacing: Min.. 3mil/3mil (0.076mm)

- Surface Finishes: HASL (lead-free/lead-based), ACCEPTER, OSP, Immersion Silver

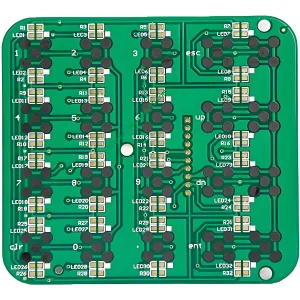

1.2 Competitive Differentiation

- 24-Hour Rapid PCB Prototyping: Equipped with German LPKF laser drills and automated exposure lines for 48-hour sample delivery.

- Military-Grade Precision: CCD auto-alignment system ensures ≤25μm interlayer deviation.

- Cost Optimization: 98%+ panel utilization rate, mixed-material customization, reducing costs by up to 30%.

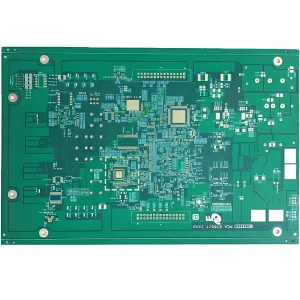

2. Industry-Specific Application Scenarios

UGPCB Standard PCBs enable precision solutions through intelligent process database matching:

- Contrôle industriel: Enhanced 4-layer designs for stable operation in -40°C to 130°C environments.

- Smart Home: ±8% impedance control for wireless module signal integrity.

- Électronique automobile: IATF 16949-certified vibration-resistant multilayer solutions.

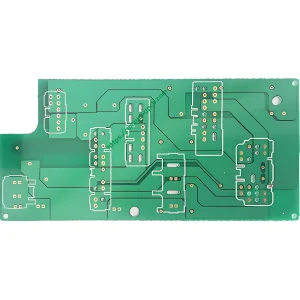

3. End-to-End Quality Assurance System

3.1 Triple Inspection Protocol

- Pre-Production: XRF heavy metal testing for raw materials.

- In-Process: 100% Zone d'intérêt + flying probe testing coverage.

- Inspection finale: TE thermal stress testing (288°C/10s).

3.2 Transparent Production Tracking

Real-time ERP updates on production milestones and online IPC-6012 test report downloads.

Call to Action

Visit the Standard PCB Board section on UGPCB’s official website to access:

✅ Instant Online Quotation (Gerber file auto-analysis supported)

✅ Free DFM Analysis

Let our experts help you reduce time-to-market by 40%!

LOGO UGPCB

LOGO UGPCB

WeChat

Scannez le code QR avec WeChat