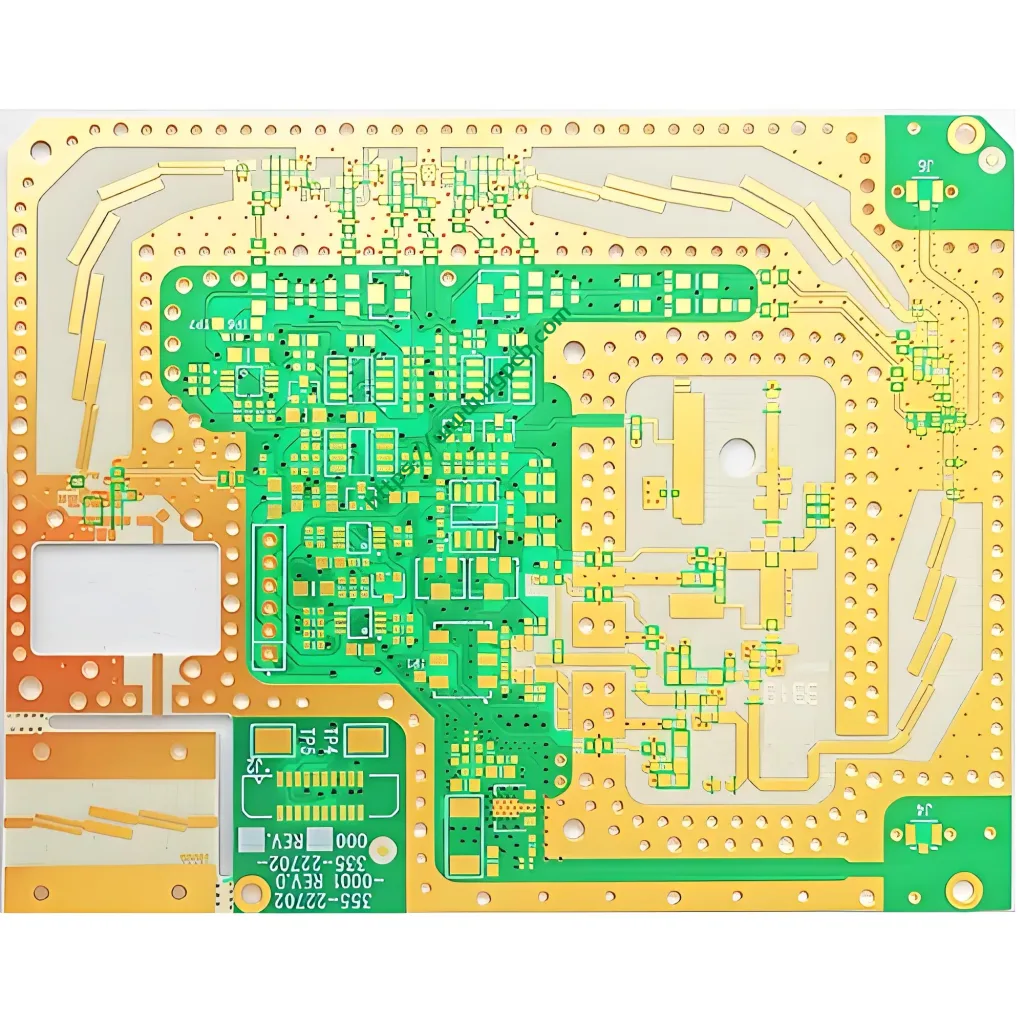

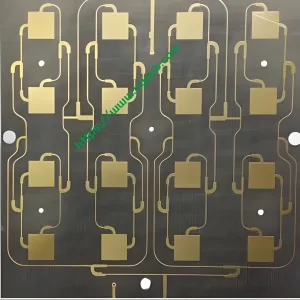

Introduction au matériel RO4003C ™

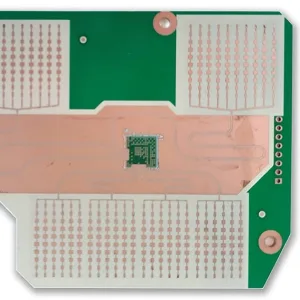

Le matériau Rogers RO4003C est un hydrocarbure / céramique renforcé de verre tissé propriétaire avec les propriétés électriques de PTFE / Verre tissée et la fabrication de l'époxy / verre.

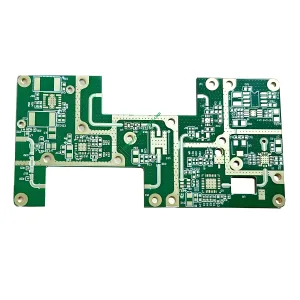

Configurations et performances électriques

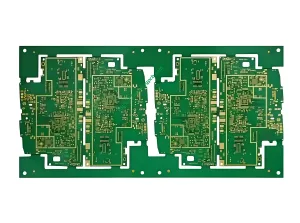

Configurations disponibles

Les stratifiés RO4003C sont disponibles dans une variété de configurations dans 1080 et 1674 Styles de tissu en verre, tous conformes aux mêmes spécifications de performance électrique en stratifié.

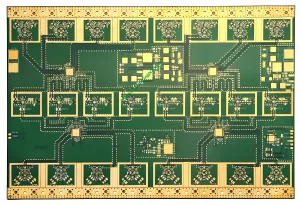

Electrical Performance Advantages

Les stratifiés RO4003C offrent une constante diélectrique étroitement contrôlée (Ne sait pas) et faible perte tout en utilisant les mêmes méthodes de traitement que l'époxy / verre standard, mais à une fraction du coût des stratifiés micro-ondes traditionnels. Contrairement aux matériaux micro-ondes basés sur PTFE, Aucune procédure spéciale de traitement ou de manutention par trous de trous n'est requise.

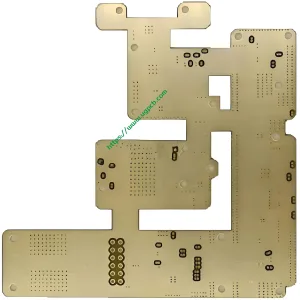

Cote d'inflammabilité

Le matériau RO4003C est sans brome et ne rencontre pas UL 94 V-0 notes. Pour les applications ou les conceptions qui nécessitent un UL 94 V-0 cote d'inflammabilité, Les stratifiés RO4835 ™ et RO4350B ™ répondent à cette exigence.

Caractéristiques et avantages clés

Caractéristiques

- Constante diélectrique (Ne sait pas): 3.38 +/- 0.05

- Dissipation Factor: 0.0027 à 10 GHz

- Thermal Expansion: Expansion thermique à faible axe z à 46 ppm/°C

Avantages

- Ideal for Multi-layer Board (MLB) Construction

- Cost-effective Manufacturing: Des processus tels que FR-4 sont moins chers à fabriquer

- High-volume Applications: Conçu pour les applications à volume élevé sensibles aux performances

- Competitive Pricing

LOGO UGPCB

LOGO UGPCB