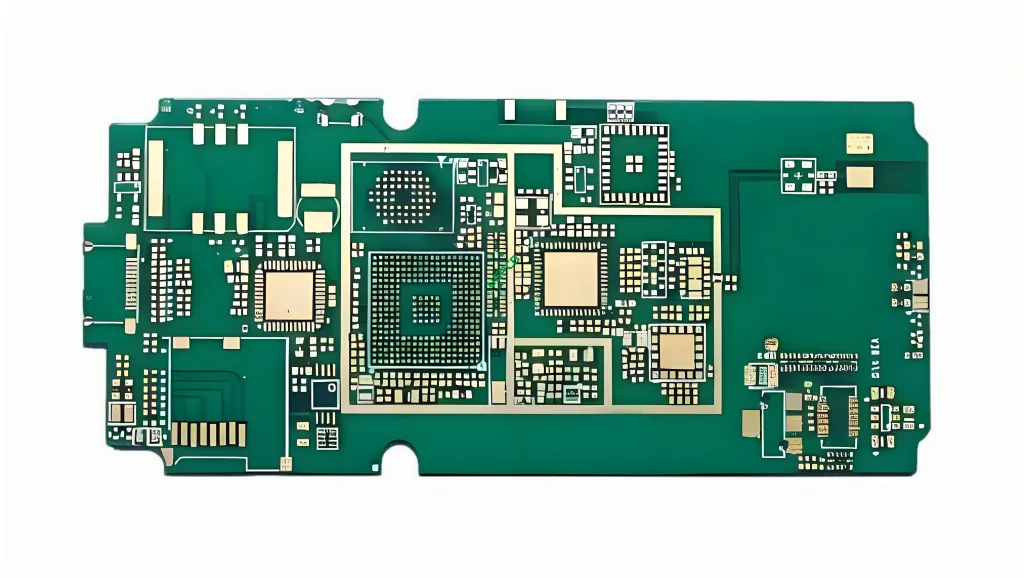

Introduction to the 6L 2+N+2 HDI Product

The 6L 2+N+2 HDI product is a high-density interconnect (IDH) circuit imprimé (PCB) designed for advanced communication applications. This guide provides a comprehensive overview of its specifications, design requirements, working principles, usage scenarios, and manufacturing process.

Definition and Design Requirements

Modèle: 6L 2+N+2 HDI

This model refers to a six-layer PCB with two internal power layers (2+N), two external signal layers, and two additional high-density interconnect layers. The ‘N’ represents the number of internal signal layers, which can vary depending on specific application needs.

Matériel: FR-4 ITEQ IT180A

The base material used is FR-4 ITEQ IT180A, known for its excellent thermal stability, résistance mécanique, and flame resistance.

Layer Composition: 6L 2+N+2 HDI

This indicates a six-layer structure with specific layer arrangements for optimized signal integrity and power distribution.

Épaisseur finie: 1.0mm

The total thickness of the finished PCB is 1.0 millimeters, ensuring durability while maintaining flexibility for various applications.

Épaisseur du cuivre: Inner 1OZ, Outer 0.5OZ

The copper traces on inner layers have a thickness of 1 ounce (once), whereas the outer layers feature a thinner 0.5 oz copper, balancing conductivity and space efficiency.

Working Principle and Purpose

Traitement de surface: Immersion Or + OSP

To enhance solderability and protect against oxidation, the PCB undergoes immersion gold plating combined with Organic Solderability Preservatives (OSP).

Minimum Trace/Space: 2.5mil/2.5mil

The PCB supports fine pitch components with a minimum trace width and spacing of 2.5 milles (thousandths of an inch), facilitating compact designs without compromising performance.

Diamètre minimum du trou: Mechanical Hole 0.2mm, Laser Hole 0.1mm

It accommodates small components through mechanical drilling down to 0.2mm and even finer laser-drilled holes at 0.1mm, enabling high-density integration.

Application: Communication Products PCB

Primarily tailored for communication devices, this PCB ensures reliable signal transmission and minimal interference, crucial for maintaining clear and consistent data flow in telecommunications systems.

Classification et matériaux

Classification: Interconnexion à haute densité (IDH) PCB

As an HDI PCB, it belongs to a category of boards specifically engineered for complex electronic devices that require intricate routing and component placement.

Matériel: FR-4 ITEQ IT180A

FR-4 is a composite material widely used in PCB manufacturing due to its balance of electrical properties, thermal resistance, et la rentabilité. The specific grade, ITEQ IT180A, further ensures consistent quality and performance.

Performance and Structure

Performance: Superior Signal Integrity

With its carefully designed layer stack and use of high-quality materials, the 6L 2+N+2 HDI PCB guarantees exceptional signal integrity, reducing crosstalk and electromagnetic interference (EMI).

Structure: Multi-Layer Arrangement

The structure comprises multiple layers strategically arranged to separate power planes from signal layers, minimizing noise and enhancing overall circuit performance. The inclusion of HDI technology allows for more intricate designs within a compact form factor.

Features and Production Process

Processus spécial: Half Hole Package Edge

A unique feature involves the use of half hole packaging along the edge, which optimizes space utilization and improves connectivity options for edge-mounted components or connectors.

Processus de production: Precision Manufacturing

Manufacturing begins with material selection and continues through precision drilling, plating, and laminating processes. Each step is meticulously controlled to ensure adherence to tight tolerances and high standards of quality.

Typical Use Cases and Scenarios

Typical Use Cases: Telecommunication Equipment

Commonly employed in telecommunication infrastructure such as routers, commutateurs, and base stations, where high-speed data transfer and signal reliability are paramount.

Usage Scenarios: High-Frequency Applications

Suitable for applications involving high-frequency signals, including wireless communication modules and RF components, where minimizing signal loss and maximizing bandwidth efficiency are critical.

En conclusion, the 6L 2+N+2 HDI PCB stands out as a sophisticated solution for demanding communication product requirements, offering unparalleled density, performance, and reliability tailored to modern telecommunications needs.

LOGO UGPCB

LOGO UGPCB