Introduction to the 2+N+2 Mobile Main Board

Présentation du produit

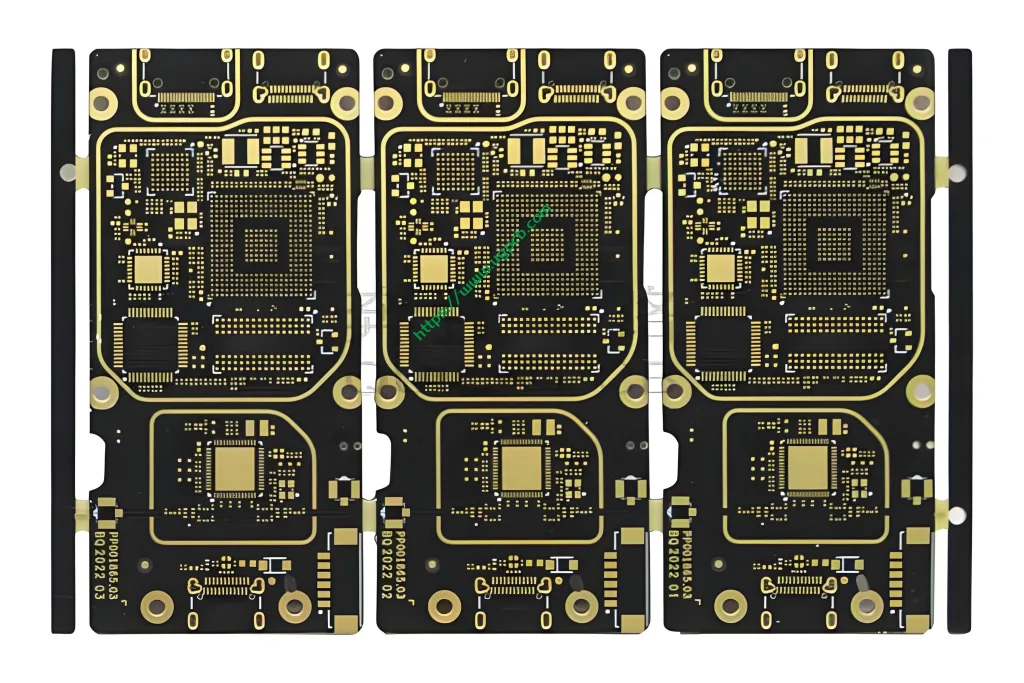

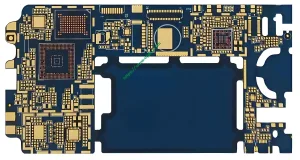

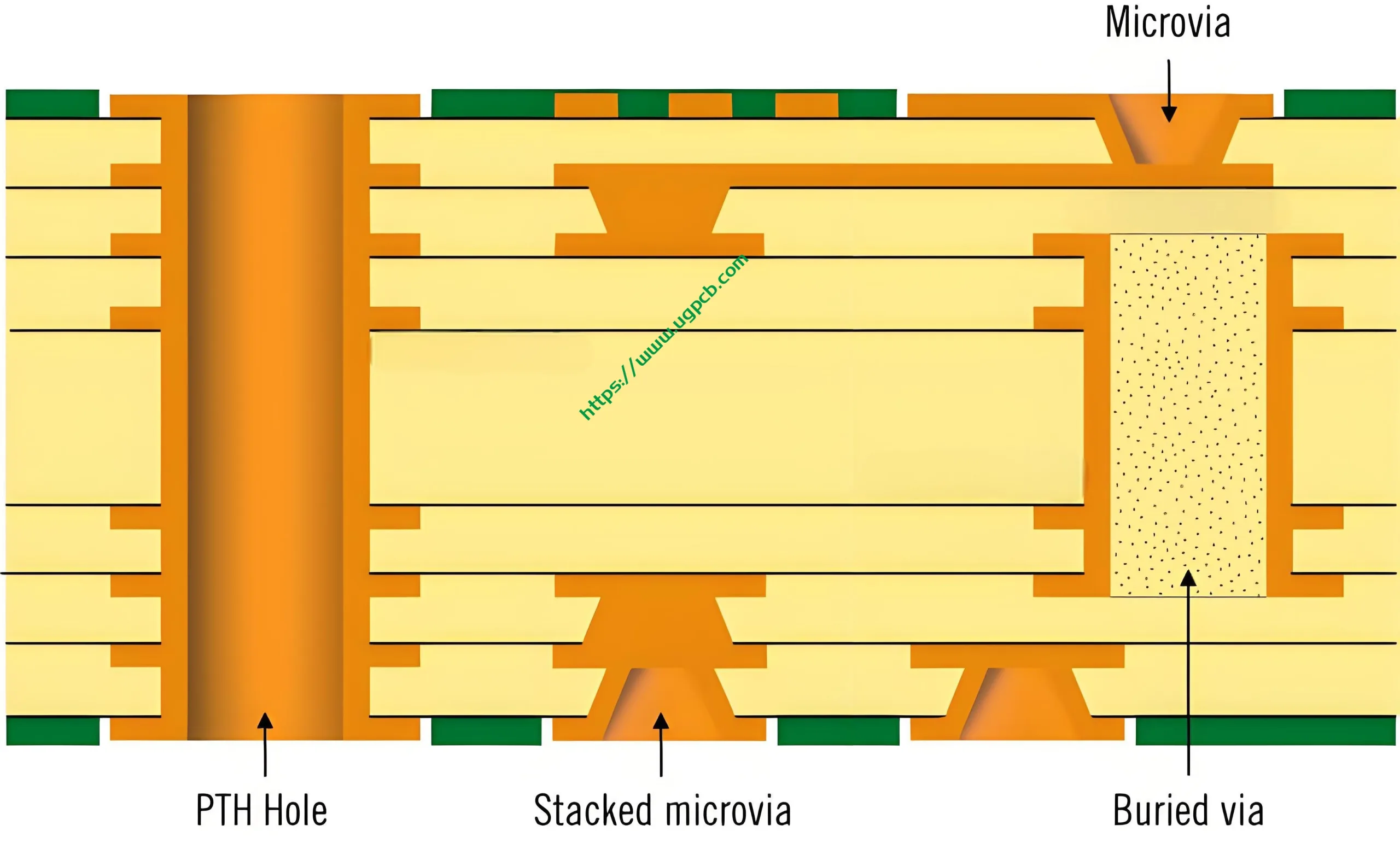

The 2+N+2 Mobile Main Board is a high-density interconnect (IDH) printed circuit board designed specifically for mobile device applications. It features an eight-layer construction with a thickness of 0.8mm, ensuring durability and compactness suitable for modern smartphones and tablets.

Exigences de conception

This main board adheres to stringent design requirements, including a minimum trace and space of 3mil/3mil and a laser-drilled hole size of 0.1mm. These specifications ensure precise connectivity and efficient miniaturization, crucial for today’s slim and powerful mobile devices.

Principe de fonctionnement

The 2+N+2 Mobile Main Board operates based on advanced HDI PCB technology, allowing for intricate component placement and signal routing within a limited space. The board utilizes high-frequency switching and optimized power distribution to manage the complex functionalities of mobile devices.

Applications

Primarily used as the core platform in smartphones and tablets, this main board integrates various electronic components, processors, memory modules, and communication interfaces. It facilitates seamless operation and enhanced performance for mobile computing.

Classification et matériaux

Classement des conseils

Classified as an HDI PCB, the 2+N+2 Mobile Main Board stands out due to its multi-layer structure and fine pitch capabilities, making it ideal for high-performance mobile devices.

Composition des matériaux

Constructed from TG170 FR4 material, known for its excellent heat resistance and mechanical stability, the board ensures reliable operation even under demanding conditions. The copper thickness of 0.5OZ further enhances conductivity and signal integrity.

Caractéristiques de performance

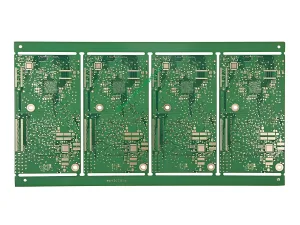

With its green or white color options, the board not only meets aesthetic preferences but also signifies different insulation levels or manufacturing batches. Surface treatments like Immersion Gold and OSP (Organic Solderability Preservatives) provide superior solderability and protection against oxidation.

Structural Features and Production Process

Structural Design

Le 2+4+2 layer arrangement in the HDI PCB structure optimizes space utilization and thermal management. This configuration supports complex routing needs without compromising signal quality or board strength.

Production Flow

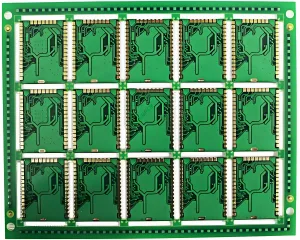

Manufacturing begins with material selection, followed by layer pressing, forage (including laser drilling for fine holes), plating, gravure, and final surface finish application. Each step is meticulously controlled to ensure the highest quality standards are met.

Use Case Scenarios

Typical Use Cases

In practical terms, the 2+N+2 Mobile Main Board is employed in flagship smartphones requiring top-tier processing power, extended battery life, and advanced features such as 5G connectivity. It also finds applications in gaming phones where thermal management and high-speed data transfer are paramount.

Conclusion

En résumé, the 2+N+2 Mobile Main Board represents a pinnacle of technological advancement in mobile device manufacturing. Its sophisticated design, adherence to strict specifications, and use of premium materials make it an indispensable component for next-generation mobile electronics.

LOGO UGPCB

LOGO UGPCB