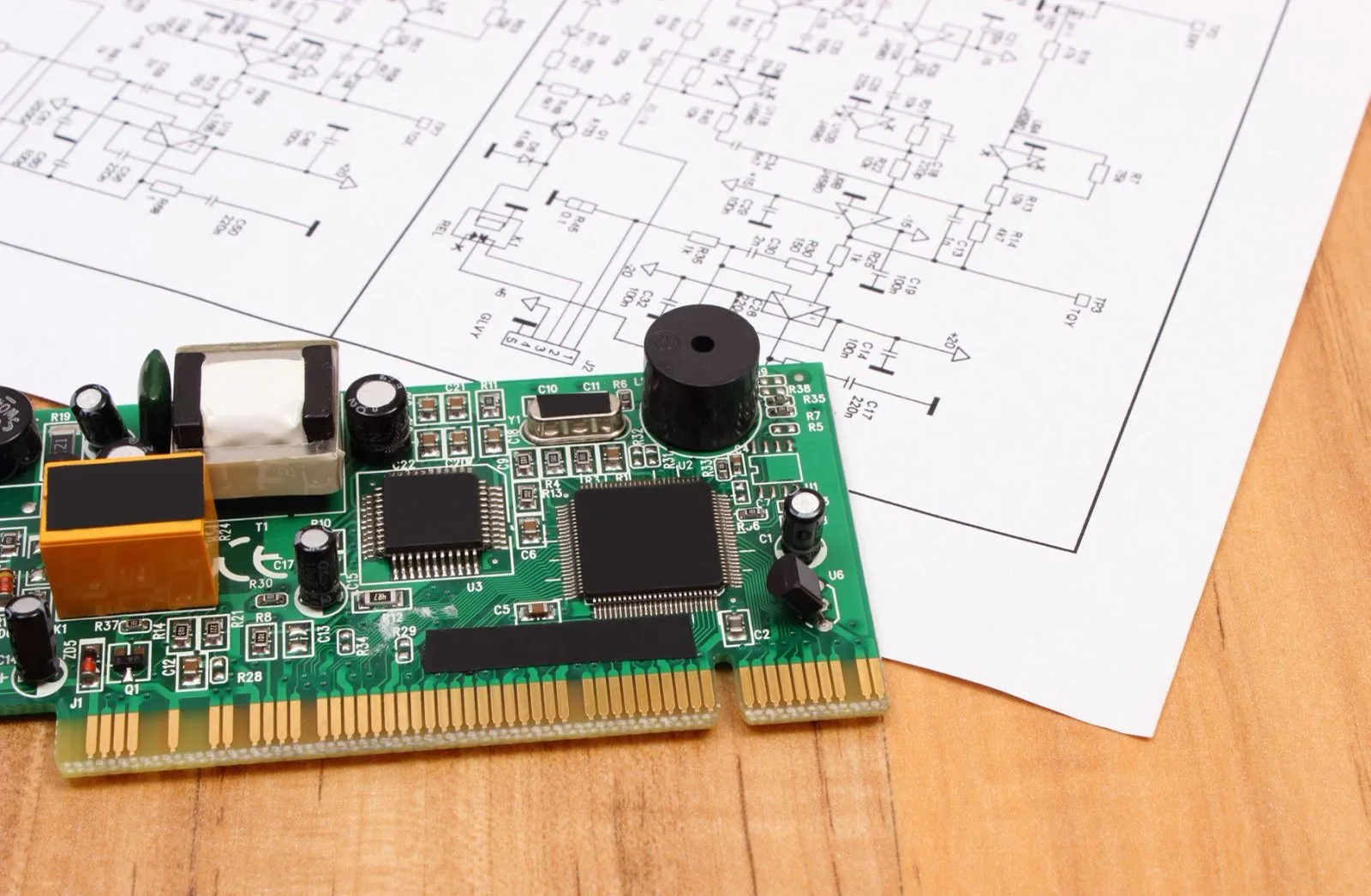

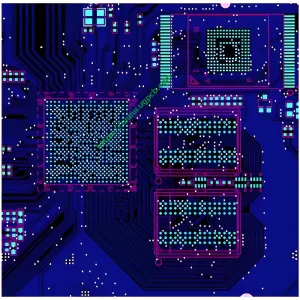

Polyvalence extraordinaire

Les planches HDI sont idéales lorsque le poids, espace, fiabilité, et les performances sont les principales préoccupations.

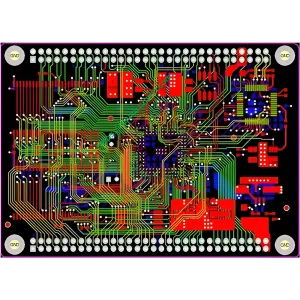

Conception compacte

Combination of Blind, Buried, and Micro Vias

La combinaison de l'aveugle, enterré, et les micro vias réduisent les exigences de l'espace du conseil d'administration.

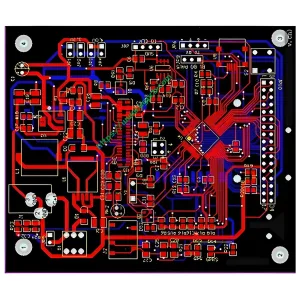

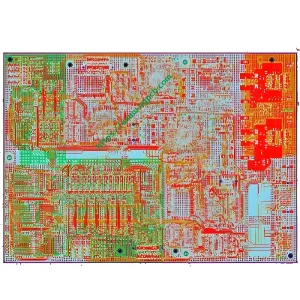

Meilleure intégrité du signal

Via-in-Pad and Blind Via Technology

HDI utilise via-pad et aveugle via la technologie, which helps keep components close to each other, Réduction des longueurs du chemin du signal.

Removal of Through-hole Stubs

La technologie HDI supprime les talons à travers, reducing signal reflections and improving signal quality.

Shorter Signal Paths

Due to shorter signal paths, HDI significantly improves signal integrity.

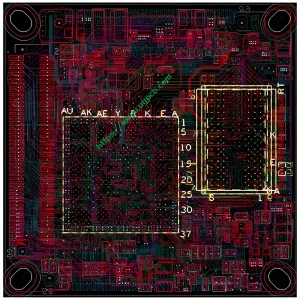

Haute fiabilité

Stacked Vias

La mise en œuvre de vias empilés fait de ces conseils une super barrière contre les conditions environnementales extrêmes.

Rentable

La fonctionnalité d'une carte à trous de 8 couches standard (PCB standard) can be reduced to a 6-layer HDI board without compromising quality.

LOGO UGPCB

LOGO UGPCB