Introduction to Blind and Buried Vias PCB

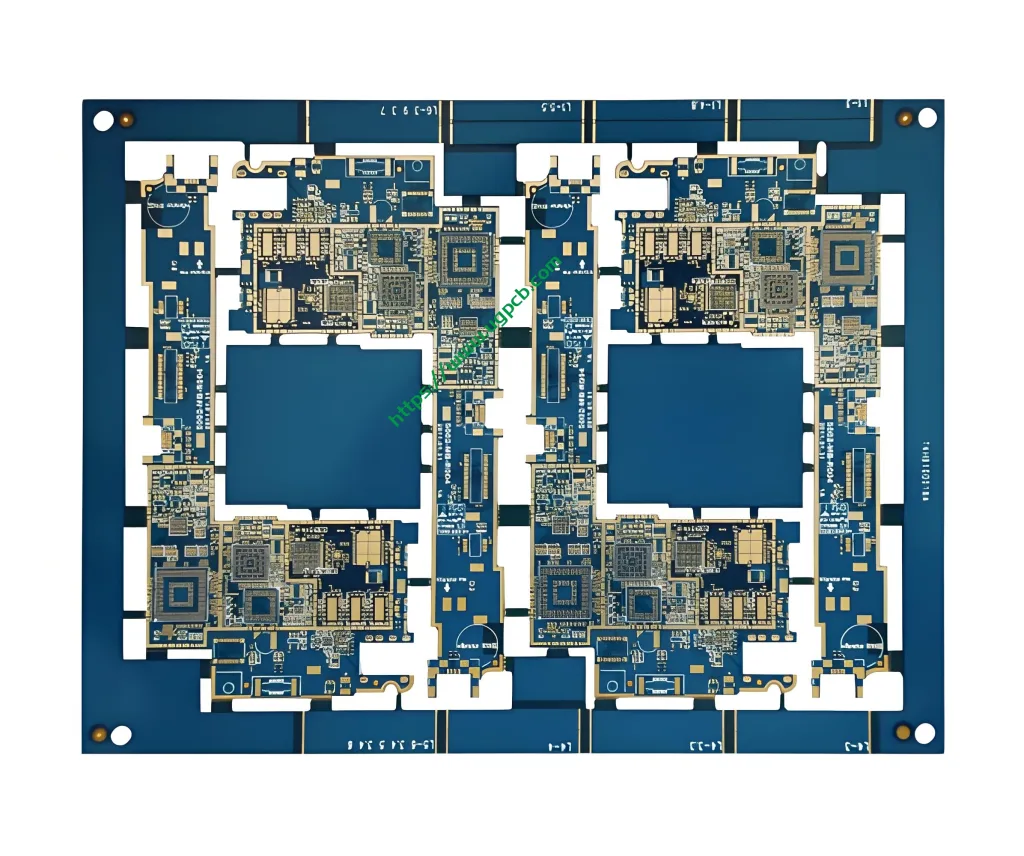

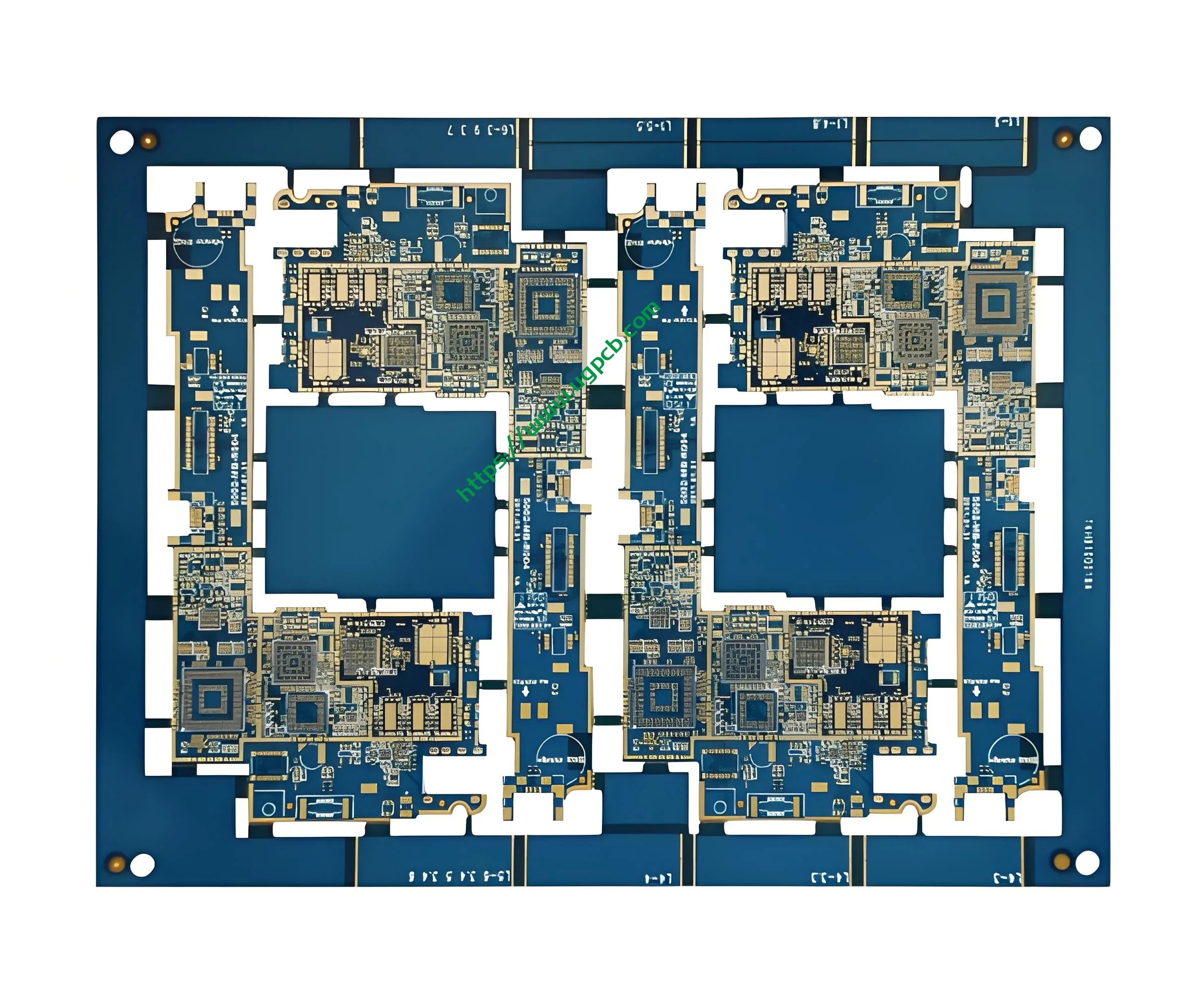

Blind and Buried Vias PCBs are advanced printed circuit boards designed for complex electronic applications. These PCBs feature blind and buried vias, which allow for intricate internal connections without compromising surface real estate. This product is ideal for high-density interconnect applications.

Objectif et applications

PCB de contrôle de sécurité

Principalement utilisé dans les systèmes de contrôle de sécurité, Blind and Buried Vias PCBs ensure reliable connectivity and data transmission in critical security setups. Their robust design makes them suitable for applications requiring high signal integrity and durability.

Classification et matériaux

Matériau TG FR4 élevé

Construit à partir de tg élevé (Température de transition du verre) FR4, Ce PCB offre une excellente stabilité thermique et résistance mécanique. L'épaisseur de cuivre de 1 oz améliore la conductivité et la dissipation de la chaleur, Le rendre adapté aux applications hautes performances.

Performance et spécifications

Structure de la couche et processus spéciaux

Le PCB se compose de 12 Couches avec une structure de couche unique: 1-2, 1-3, 4-6, 7-12. Il incorpore des vias aveugles et enterrés, qui permettent des connexions internes complexes sans compromettre l'immobilier de surface du conseil. La taille minimale du trou est de 0,2 mm (8mil), Accueillir des composants à pas fins.

Traitement de surface et trace / espace

Le traitement de surface est d'immersion Tin, offrant une bonne résistance à la soudabilité et à la corrosion. La configuration de trace / espace est de 4mil / 4mil (0.1Mm / 0,1 mm), Assurer la disposition des circuits précis et dense.

Processus de production

Étapes impliquées dans la fabrication

- Préparation des matériaux: Les planches TG FR4 élevées sont coupées aux dimensions requises.

- Empilement de calques: Les couches sont empilées en fonction de la structure spécifiée.

- Forage: Les vias aveugles et enterrés sont forés de précision.

- Placage: Les trous sont plaqués pour créer des connexions électriques entre les couches.

- Gravure: Le cuivre inutile est retiré pour former le motif de circuit souhaité.

- Traitement de surface: Le conseil d'administration subit un traitement d'étain immersion pour une soudabilité améliorée.

- Inspection: Chaque planche est soigneusement inspectée pour assurer la qualité et la conformité avec les spécifications.

Caractéristiques et avantages clés

Intégration des technologies avancées

L'intégration des vias aveugles et enterrés permet des conceptions plus complexes et compactes, Réduire la taille globale du PCB tout en maintenant des fonctionnalités élevées.

Haute fiabilité et durabilité

L'utilisation de matériaux TG FR4 élevés garantit que le PCB peut résister à des températures élevées et des conditions difficiles, le rendre fiable pour une utilisation à long terme.

Intégrité du signal amélioré

L'épaisseur de cuivre de 1 oz et la configuration précise de trace / espace contribuent à l'intégrité du signal supérieur, crucial pour les applications de contrôle de sécurité où la précision des données est primordiale.

Des cas d'utilisation et des scénarios

Systèmes de sécurité

Dans les systèmes de contrôle de la sécurité, the Blind and Buried Vias PCB provides a stable platform for various sensors and communication devices, Assurer le fonctionnement transparent et la protection des données.

Automatisation industrielle

Pour l'automatisation industrielle, Ce PCB prend en charge le transfert de données à grande vitesse et la connectivité robuste, Essential pour contrôler efficacement les processus de machines et de surveillance.

Aérospatial et défense

Dans les applications aérospatiales et de défense, La stabilité thermique élevée et la fiabilité du PCB le rendent adapté aux équipements et systèmes critiques de mission.

Conclusion

Blind and Buried Vias PCBs stand out as high-performance solutions for complex electronic applications, en particulier dans les systèmes de contrôle de la sécurité. Their advanced features, Matériaux robustes, et le processus de fabrication précis assure la fiabilité et l'efficacité des environnements exigeants.

LOGO UGPCB

LOGO UGPCB