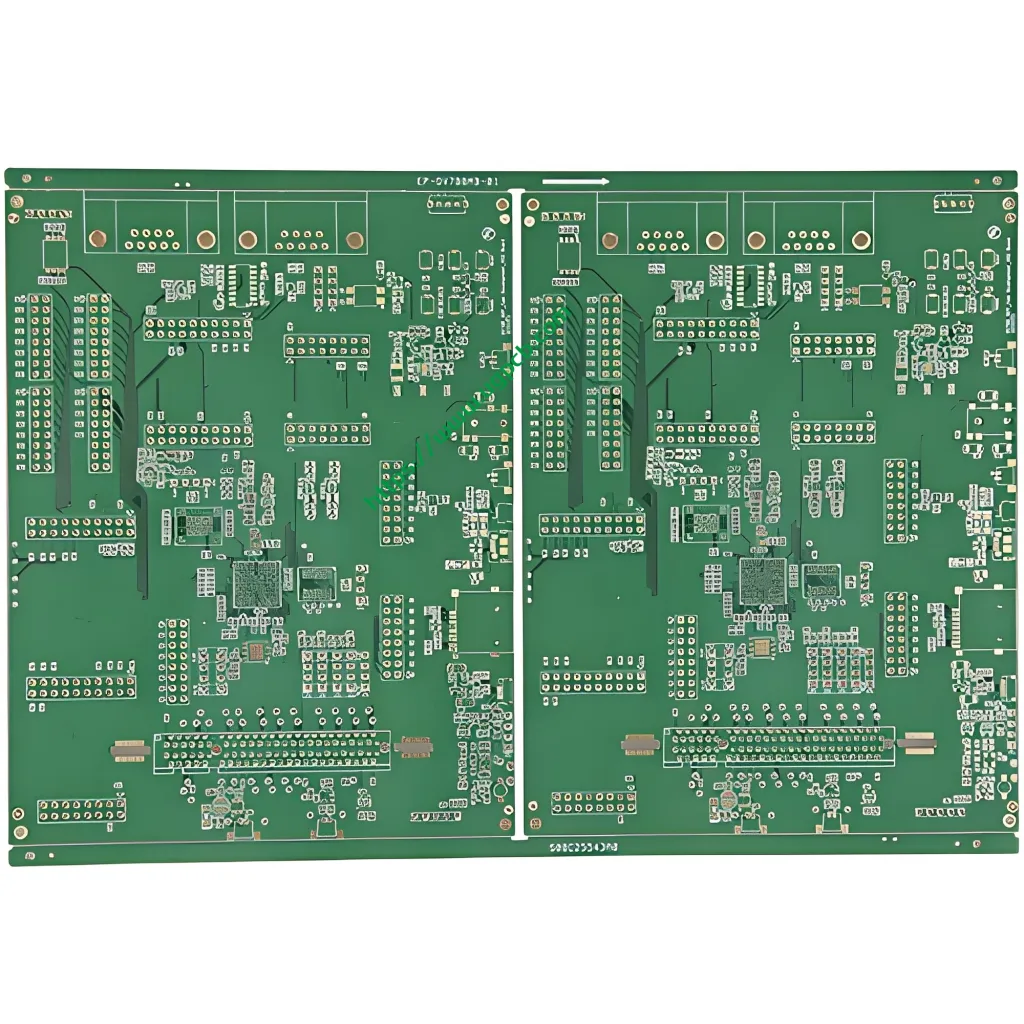

Définition du PCB HDI

Interconnexion à haute densité (IDH) est simplement un PCB avec un nombre plus élevé d'interconnexions dans la plus petite empreinte. Cela conduit à la miniaturisation de la carte de circuit imprimé. Les composants sont placés plus près les uns des autres et l'espace de la carte est considérablement réduit, Mais la fonctionnalité n'est pas compromise.

Characteristics of HDI PCB

Plus précisément, un PCB avec une moyenne de 120 à 160 Les broches par pouce carré sont considérées comme un PCB HDI. Les conceptions HDI combinent le placement des composants dense et le routage polyvalent. HDI popularized microporous technology, creating denser circuits by implementing microvias, vias enterrés, et vias aveugles. Le forage réduit du cuivre est une caractéristique des conceptions HDI.

Avantages du PCB HDI

Polyvalence extraordinaire

Les planches HDI sont idéales lorsque le poids, espace, fiabilité, et les performances sont les principales préoccupations.

Conception compacte

La combinaison de l'aveugle, enterré, et les micro vias réduisent les exigences de l'espace du conseil d'administration.

Meilleure intégrité du signal

HDI utilise via-pad et aveugle via la technologie. Cela aide à garder les composants proches les uns des autres, Réduction des longueurs du chemin du signal. La technologie HDI supprime les talons à travers, réduisant ainsi les réflexions du signal, améliorant ainsi la qualité du signal. Donc, Il améliore considérablement l'intégrité du signal en raison de chemins de signal plus courts.

Haute fiabilité

La mise en œuvre de vias empilés fait de ces conseils une super barrière contre les conditions environnementales extrêmes.

Rentable

La fonctionnalité d'une carte à trous de 8 couches standard (PCB standard) can be reduced to a 6-layer HDI board without compromising the quality. This makes HDI PCBs a cost-effective solution.

LOGO UGPCB

LOGO UGPCB