Matériaux PCB de base en métal, y compris les PCB en aluminium, PCB à base de cuivre, PCB à base de fer. En raison de l'avantage du coût, L'aluminium est très populaire sur le marché des lampes LED.

PCB de noyau métallique signifie que le noyau (base) Le matériau du PCB est en métal, pas commun FR4 / CEM1-3, etc.. actuellement, Les métaux les plus couramment utilisés dans les fabricants de MCPCB sont l'aluminium, alliages en cuivre et en acier. L'aluminium a une bonne capacité de transfert de chaleur et de dissipation thermique, Mais c'est relativement bon marché; Le cuivre a de meilleures performances mais est relativement cher, et l'acier peut être divisé en acier ordinaire et en acier inoxydable. C'est plus difficile que l'aluminium et le cuivre, Mais c'est aussi moins thermique. Les gens choisiront leur propre base / Matériaux de base pour différentes applications.

Les avantages incluent:

Réduire la température de fonctionnement.

Réduire la taille des PCB.

Augmenter la densité de puissance. Extension de la durée de vie des puces

Améliorer les propriétés thermiques et mécaniques du produit.

Combiner la puissance et le contrôle.

Améliorer la durabilité des produits.

Meilleure utilisation de la technologie de montage de surface.

Accélérer le dissipateur de chaleur et d'autres matériels d'installation.

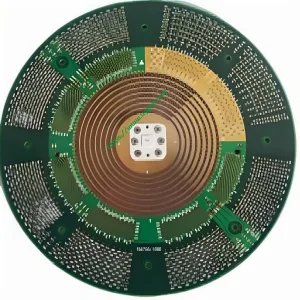

Copper Core PCB est un substrat de cuivre + couche d'isolation + PCB de la couche de circuit de cuivre, également connu sous le nom de PCB de substrat de cuivre, PCB à base de cuivre, PCB vêtu de cuivre.

En tant que fabricant MCPCB, UGPCB fabrique une variété de PCB de base en cuivre pour les clients

LOGO UGPCB

LOGO UGPCB