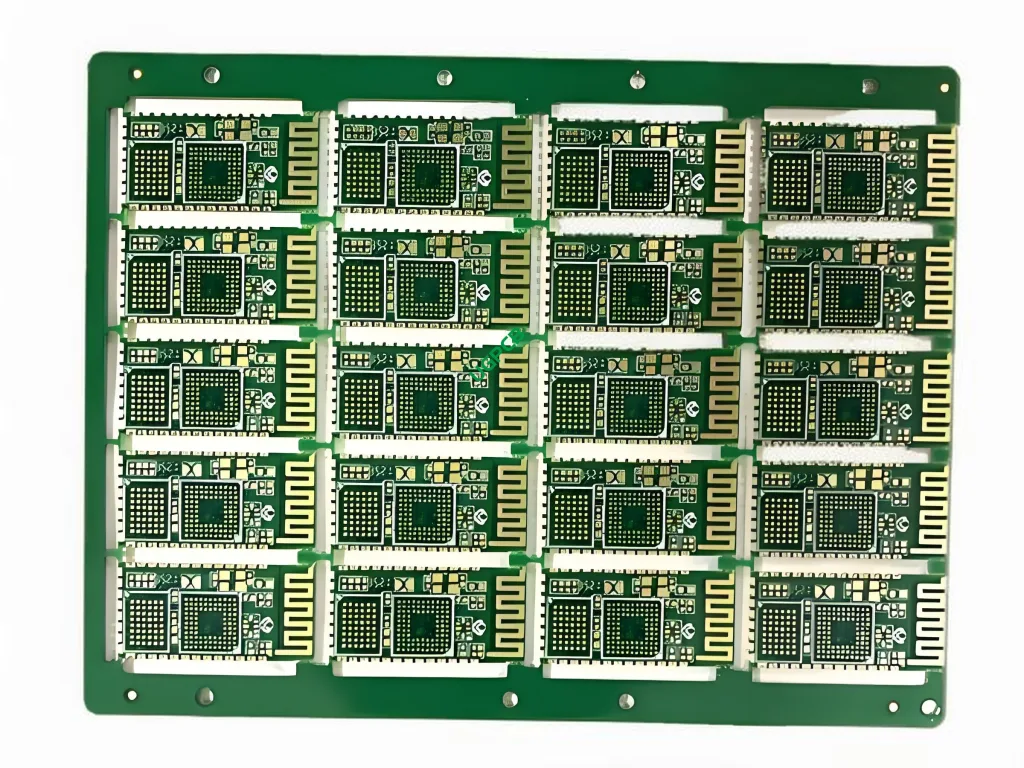

Half Hole WiFi Module PCB: A Comprehensive Overview

Product Profile

The Half Hole WiFi Module PCB is a sophisticated electronic component designed to facilitate seamless Wi-Fi connectivity in various devices. This module combines the advantages of both surface mount and through-hole technology, making it highly versatile for diverse applications.

Définition

A Half Hole WiFi Module PCB refers to a printed circuit board (PCB) that incorporates components with both surface mount (CMS) and through-hole (THD) technologies. It is specifically engineered to support Wi-Fi modules, enabling efficient wireless communication.

Exigences de conception

The design of this PCB adheres to stringent requirements to ensure optimal performance:

- Matériel: High-quality FR4, known for its excellent electrical properties and durability.

- Calques: Four layers to accommodate complex circuitry while maintaining compactness.

- Couleur: Available in Black and White, providing aesthetic flexibility.

- Épaisseur finie: 1.0mm to strike a balance between robustness and space efficiency.

- Épaisseur du cuivre: 1once, ensuring reliable conductivity.

- Traitement de surface: Immersion Gold to enhance solderability and corrosion resistance.

- Trace / espace min: 4mil(0.1mm), allowing for fine detailing and high-density layouts.

Principe de fonctionnement

The Half Hole WiFi Module PCB operates by integrating with Wi-Fi modules to provide wireless communication capabilities. It uses embedded antennas and radio-frequency (RF) components to transmit and receive data over Wi-Fi networks. The surface mount components offer high-speed signal processing, while the through-hole components ensure stable mechanical connections.

Applications

This PCB is widely used in:

- IoT Devices: Enabling smart home appliances and industrial equipment to connect wirelessly.

- Electronique grand public: Integrating Wi-Fi functionality into gadgets like smart TVs and gaming consoles.

- Automotive Systems: Supporting infotainment systems and advanced driver assistance features.

- Équipement médical: Facilitating remote monitoring and diagnostic tools.

Types and Classification

The Half Hole WiFi Module PCB can be classified based on several criteria:

- By Technology: Combination of SMD and THD.

- By Application: General purpose or specific use cases like automotive or medical.

- By Frequency Band: Supporting 2.4GHz, 5GHz, or dual-band operations.

Composition des matériaux

Constructed primarily from FR4, this PCB material offers:

- Superior thermal stability

- High mechanical strength

- Excellent electrical insulation properties

Performance Metrics

Key performance indicators include:

- Signal Integrity: Maintained through careful layout design and impedance matching.

- Fiabilité: Ensured by rigorous testing protocols and quality control measures.

- Compatibility: With a wide range of Wi-Fi standards including 802.11 b/g/n/ac.

Caractéristiques structurelles

The PCB’s structure comprises:

- Multilayer stackup for enhanced signal integrity

- Precision-etched traces and spaces for fine circuitry

- Robust through-hole plating for durable mechanical connections

Distinctive Traits

Notable characteristics include:

- Versatility in mounting options (SMD and THD)

- High signal-to-noise ratio due to optimized layout

- Resistance to environmental factors such as humidity and temperature variations

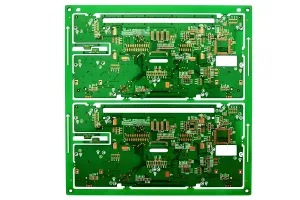

Production Workflow

The manufacturing process involves several stages:

- Conception et disposition: Using advanced CAD software to create precise schematics.

- Préparation des matériaux: Cutting FR4 sheets to size and cleaning them thoroughly.

- Gravure: Applying etchant to remove unwanted copper from the board.

- Placage: Immersing the board in a gold bath for surface finishing.

- Assemblée: Soldering surface mount and through-hole components accurately.

- Essai: Conducting functional tests to ensure compliance with specifications.

- Contrôle de qualité: Final inspection for defects and performance validation.

Cas d'utilisation

Typical scenarios where this PCB finds application include:

- Smart Home Automation Systems

- Portable Medical Diagnostic Tools

- In-vehicle Communication Networks

- Industrial Machinery with Wireless Connectivity Needs

En résumé, the Half Hole WiFi Module PCB stands out as an innovative solution catering to the growing demand for reliable wireless communication in various sectors. Its unique blend of SMD and THD technologies, along with rigorous design and manufacturing standards, ensures top-notch performance and broad applicability.

LOGO UGPCB

LOGO UGPCB