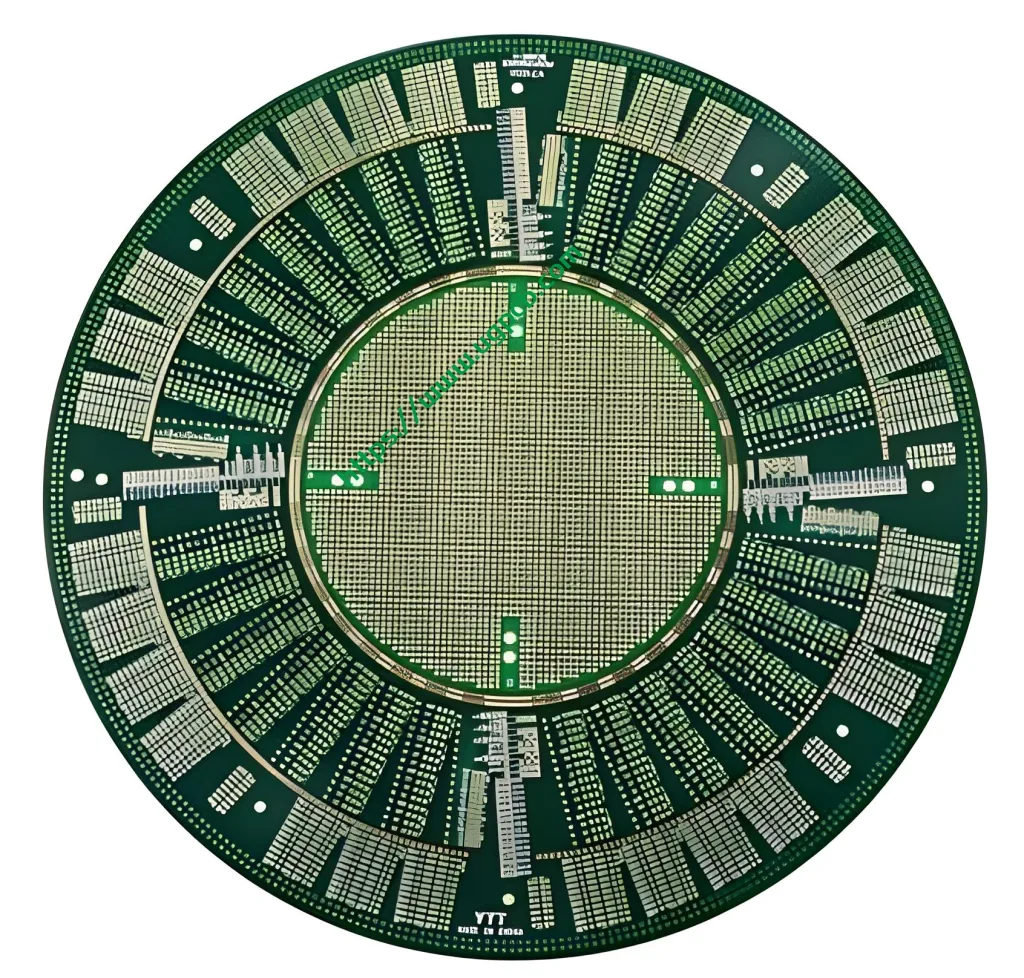

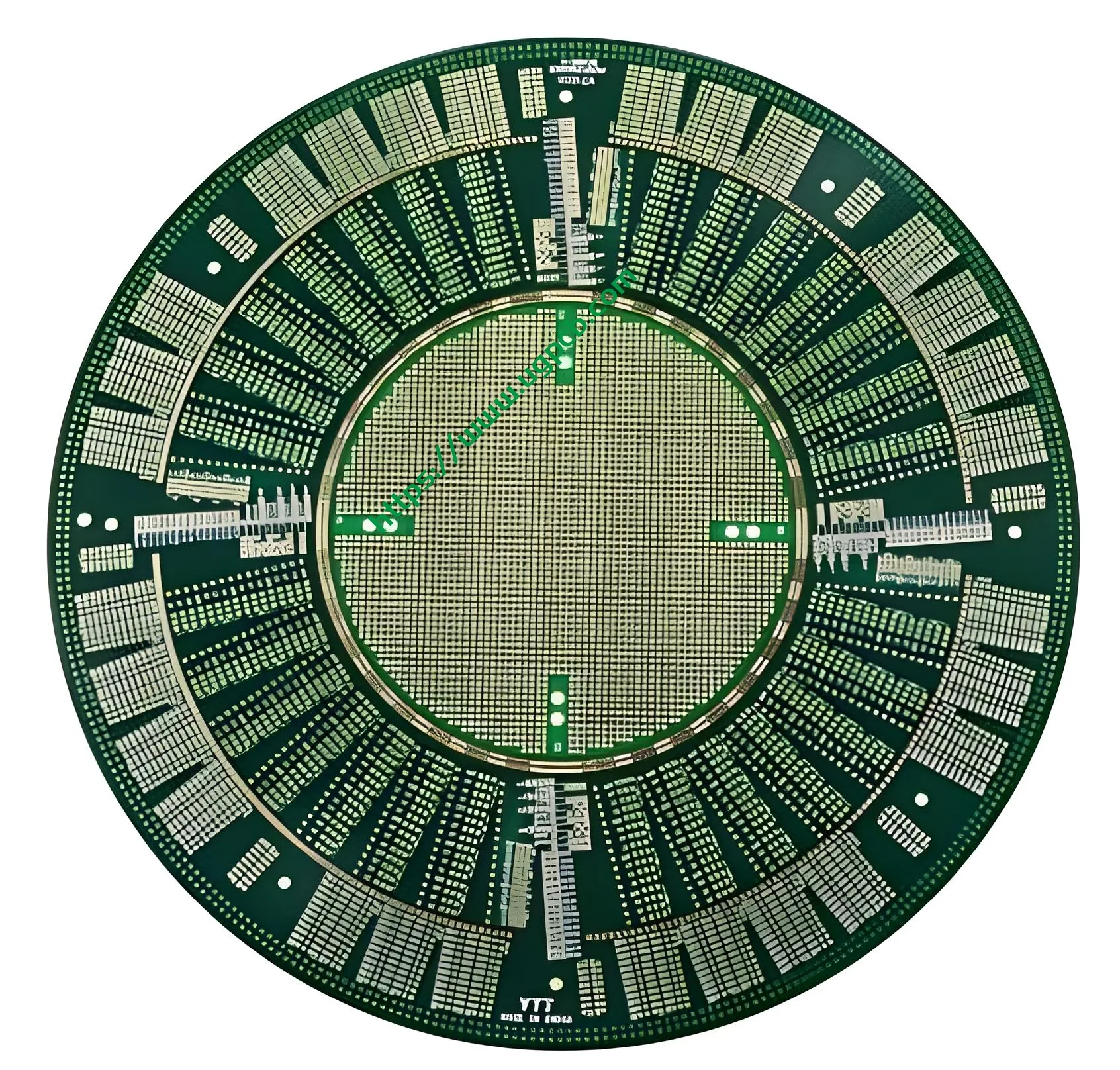

Introduction to IC Chip Test PCB

Overview and Definition

An IC Chip Test PCB, or Integrated Circuit Chip Test Printed Circuit Board, is a specialized circuit board designed for testing integrated circuit chips. It ensures that the chips meet the required specifications before they are used in electronic devices.

Principe de fonctionnement

The IC Chip Test PCB works by connecting the integrated circuit chip to various test points on the PCB. These test points measure the electrical characteristics of the chip, such as voltage, actuel, and resistance, to verify its functionality.

Applications

IC Chip Test PCBs are used in the manufacturing and quality control processes of electronic devices. They are essential for ensuring that only functioning and reliable chips are used in the final products.

Types of IC Chip Test PCBs

There are different types of IC Chip Test PCBs based on their design and functionality:

- Functional Test PCBs: Used to test the overall functionality of the chip.

- Parameter Test PCBs: Used to measure specific parameters like power consumption, vitesse, et la température.

Matériel et construction

- Matériel: TU872SLS, un matériau époxy de haute qualité.

- Calques: 20 couches, fournir une robustesse et une meilleure intégrité du signal.

- Couleur: Disponible en vert ou blanc.

- Épaisseur finie: 2.0mm, Assurer la durabilité tout en étant mince.

- Épaisseur du cuivre: 1once, qui offre une bonne conductivité.

- Traitement de surface: Immersion gold with a thickness of at least 3U”, Amélioration de la résistance à la corrosion et de la soudabilité.

Caractéristiques de performance

IC Chip Test PCBs are designed to accurately test the performance of integrated circuit chips. They support high-speed data transfer and are built to withstand repeated usage over time. La finition en or d'immersion assure des performances et une fiabilité durables.

Caractéristiques structurelles

The structure of an IC Chip Test PCB includes multiple layers of copper traces sandwiched between layers of substrate material. Cette conception multicouche aide à gérer la dissipation de la chaleur et à améliorer les performances électriques. Le PCB est recouvert d'une couche protectrice pour éviter les dommages et assurer la longévité.

Processus de production

The production of an IC Chip Test PCB involves several steps:

- Conception: Utilisation d'un logiciel spécialisé pour créer la disposition du circuit.

- Gravure: Retirer l'excès de cuivre pour former les motifs souhaités.

- Laminage: Combiner plusieurs couches ensemble.

- Placage: Ajout d'une fine couche de métal pour améliorer la connectivité.

- Inspection: Assurer que le PCB répond aux normes de qualité.

- Assemblée: Montage des composants sur le PCB.

- Essai: Vérification des fonctionnalités et des performances.

Cas d'utilisation

IC Chip Test PCBs are used in various applications including:

- Electronique grand public: Téléphones portables, comprimés, montres intelligentes.

- Automobile: In-car systems for navigation and entertainment.

- Dispositifs médicaux: Équipement médical portable.

- Automatisation industrielle: Control systems for machinery and robotics.

En conclusion, IC Chip Test PCBs play a crucial role in the electronics manufacturing process by ensuring the reliability and functionality of integrated circuit chips. Leur adoption généralisée dans différentes industries met en évidence leur polyvalence et leur importance dans les appareils électroniques modernes.

LOGO UGPCB

LOGO UGPCB