Introduction à 4 Couches de contrôle industriel PCBA

Aperçu

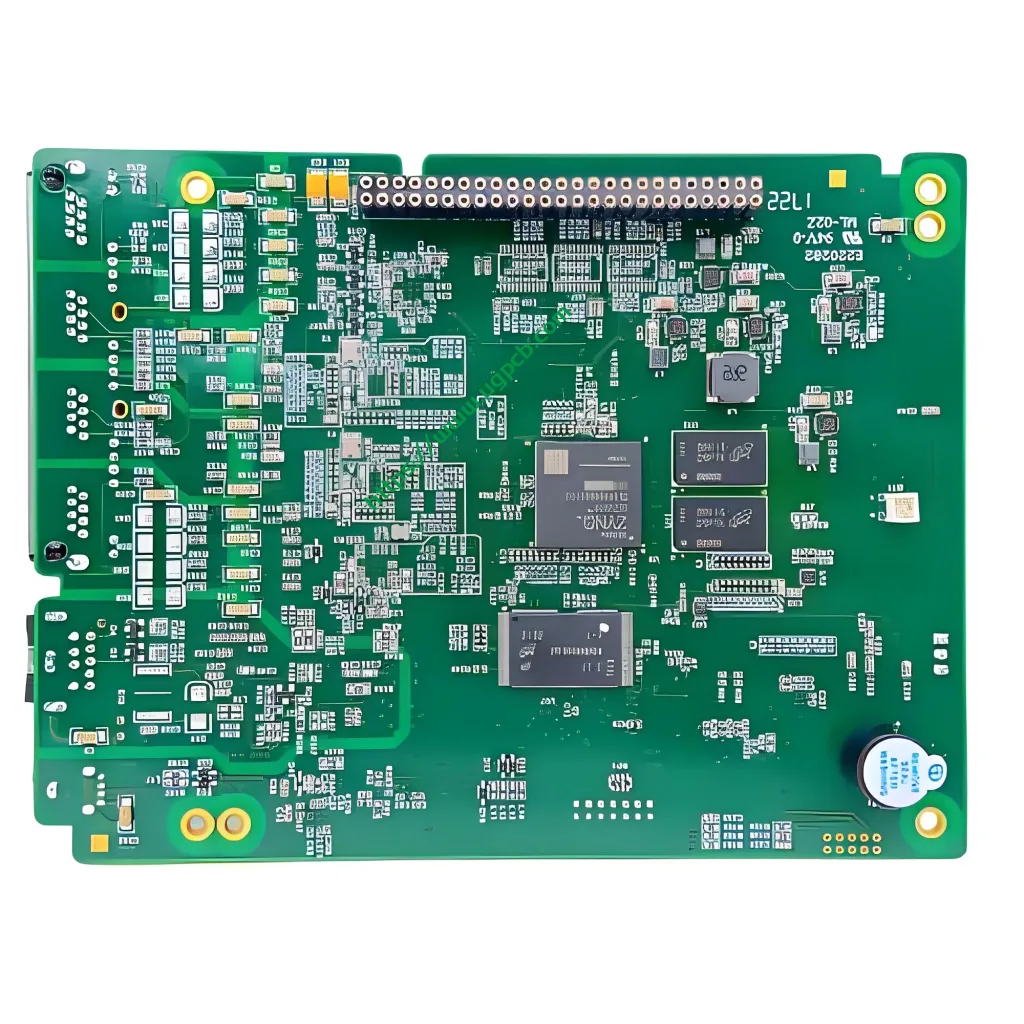

Le 4 Couches Industrial Control PCBA est un assemblage de cartes de circuit imprimé sophistiqué conçu pour les applications de contrôle industriel. Il comprend quatre couches de matériaux conducteurs, qui permet des circuits complexes et un placement de composants à haute densité. Ce PCBA est essentiel pour divers systèmes d'automatisation et de contrôle industriels en raison de sa fiabilité et de ses performances.

Définition

UN 4 Couches Industrial Control PCBA fait référence à un ensemble de cartes de circuit imprimé à plusieurs couches qui intègre quatre couches de traces de cuivre, séparés par des couches diélectriques. Cette conception permet des conceptions de circuits plus compactes et efficaces adaptées aux environnements industriels.

Principe de fonctionnement

Le principe de travail d'un 4 Couches de contrôle industriel PCBA implique l'utilisation de plusieurs couches de traces de cuivre conductrices intégrées dans des couches de substrat non conductrices. Ces couches sont interconnectées via vias (trous plaqués) Pour permettre aux signaux électriques de voyager entre différentes couches. La technologie de montage de surface (CMS) et la technologie à travers (Tht) Les composants sont soudés sur le PCB, Création d'un circuit fonctionnel.

Applications

Ce type de PCBA est largement utilisé dans les systèmes de contrôle industriel, y compris:

- Équipement d'automatisation

- Robotique

- Unités de contrôle de la machine

- Interfaces de capteur

- Cartes de distribution d'électricité

Classification

Les PCBA peuvent être classés en fonction de plusieurs critères:

- Par nombre de couches: Simple face, double face, multicouche (y compris 4 couches)

- Par type de composants: À travers le trou, support de surface, ou une combinaison des deux

- Par les normes de l'industrie: Rohs conforme, sans plomb, etc..

Matériels

Les matériaux principaux utilisés dans la construction d'un 4 Couches de contrôle industriel PCBA incluent:

- Feuille de cuivre pour les couches conductrices

- Fibre-verre ou matériaux composites pour les couches diélectriques

- HASL sans plomb (Niveau d'assemblage du dissipateur de chaleur) finition de surface

- Masque de soudure verte pour la protection et l'isolation

Performance

Les performances de ce PCBA se caractérisent par:

- Haute conductivité thermique en raison des couches de cuivre

- Faible perte de signal et intégrité élevée du signal

- Résistance aux facteurs environnementaux tels que l'humidité, Variations de température, et contrainte mécanique

- Conformité aux ROH et normes d'assemblage sans plomb

Structure

La structure d'un 4 Les couches de contrôle industriel PCBA incluent généralement:

- Quatre couches de traces de cuivre séparées par des couches diélectriques

- Vias (trous plaqués) pour la connectivité inter-couches

- Montage de surface et composants à travers du trou soudé sur la planche

- Un masque de soudure verte couvrant la couche supérieure pour la protection et l'identification

Caractéristiques

Les caractéristiques clés de ce PCBA incluent:

- Design à haute densité et compact adapté aux applications limitées dans l'espace

- Capacités de gestion thermique supérieures

- Durabilité et longévité accrue dans des environnements industriels durs

- Compatibilité avec une large gamme de composants électroniques

Processus de production

Le processus de production d'un 4 Les couches de contrôle industriel PCBA implique plusieurs étapes:

- Conception: Utilisation d'un logiciel spécialisé pour créer la disposition du circuit et le placement des composants.

- Préparation des matériaux: Sélection et préparation du feuille de cuivre, couches diélectriques, et autres matériaux.

- Empilement de calques: Empiler les couches de cuivre et de matériaux diélectriques.

- Via le forage: Forage des trous à travers les couches empilées pour vias.

- Placage: Planter les vias avec le cuivre pour assurer la connectivité électrique.

- Gravure: Retirer l'excès de cuivre pour former le motif de circuit souhaité.

- Placement des composants: Montage de surface de soudage et composants à travers sur le PCB.

- Essai: Effectuer des tests rigoureux pour assurer la fonctionnalité et le respect des normes.

- Inspection finale: Assurer le PCBA répond à tous les critères de qualité et de performance.

Cas d'utilisation

Cas d'utilisation courants pour le 4 Couches de contrôle industriel PCBA incluent:

- Systèmes d'automatisation industrielle où la haute fiabilité et les performances sont cruciales

- Bras et machines robotiques nécessitant un contrôle précis

- Fabrication avec des conditions environnementales exigeantes

- Panneaux de distribution et de contrôle de l'énergie dans les industries lourdes

Conclusion

Le 4 Couches Industrial Control PCBA est une solution avancée et fiable pour diverses applications de contrôle industriel. Sa conception multicouche, Matériaux à haute performance, Et la conformité aux normes de l'industrie en fait un choix idéal pour les ingénieurs et les fabricants à la recherche de solutions électroniques robustes et efficaces.

LOGO UGPCB

LOGO UGPCB