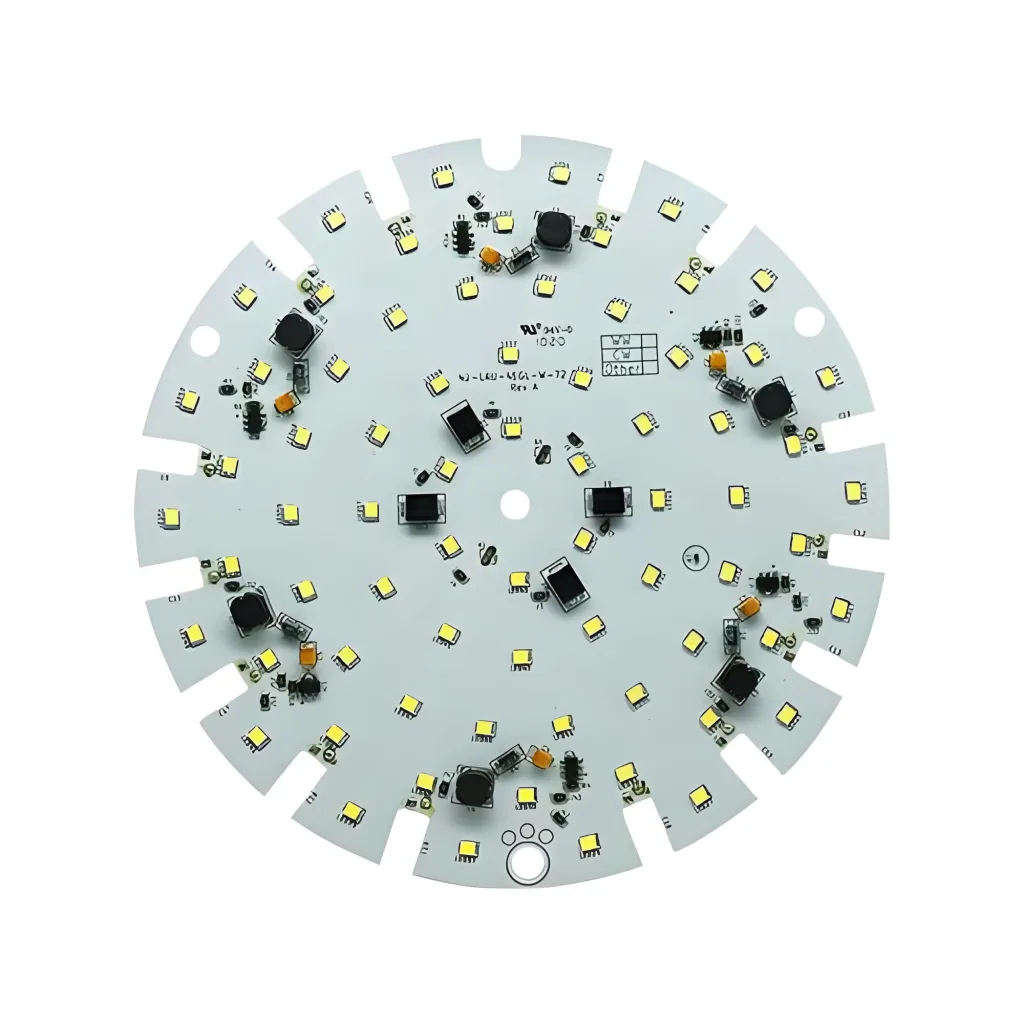

Présentation du PCBA LED légère

Introduction

Le PCBA LED léger est un ensemble de cartes de circuit imprimé compacte et efficace conçue pour les applications d'éclairage LED. Ce PCBA fonctionnait 1-2 couches de matériaux conducteurs, Le rendre adapté à des conceptions de circuits plus simples tout en conservant des performances et une fiabilité élevées.

Définition

Un PCBA LED léger fait référence à un ensemble de cartes de circuit imprimé qui intègre la technologie de montage de surface (CMS) ou la technologie à travers (Tht) composants spécifiquement pour les applications d'éclairage LED. Le PCBA comprend tous les composants électroniques nécessaires soudés sur le PCB, Prêt pour l'intégration dans un système d'éclairage LED.

Principe de fonctionnement

Le principe de travail d'un PCBA LED léger implique d'utiliser des traces de cuivre conductrices sur un substrat non conducteur pour créer des voies électriques. Ces voies relient divers composants électroniques tels que les LED, résistances, et condensateurs. Lorsque le courant électrique traverse ces voies, il alimente les LED, Les faire émettre de la lumière.

Applications

Ce type de PCBA est largement utilisé dans diverses applications d'éclairage LED, y compris:

- Éclairage résidentiel et commercial

- Systèmes d'éclairage automobile

- Éclairage de signalisation et d'affichage

- Éclairage décoratif et architectural

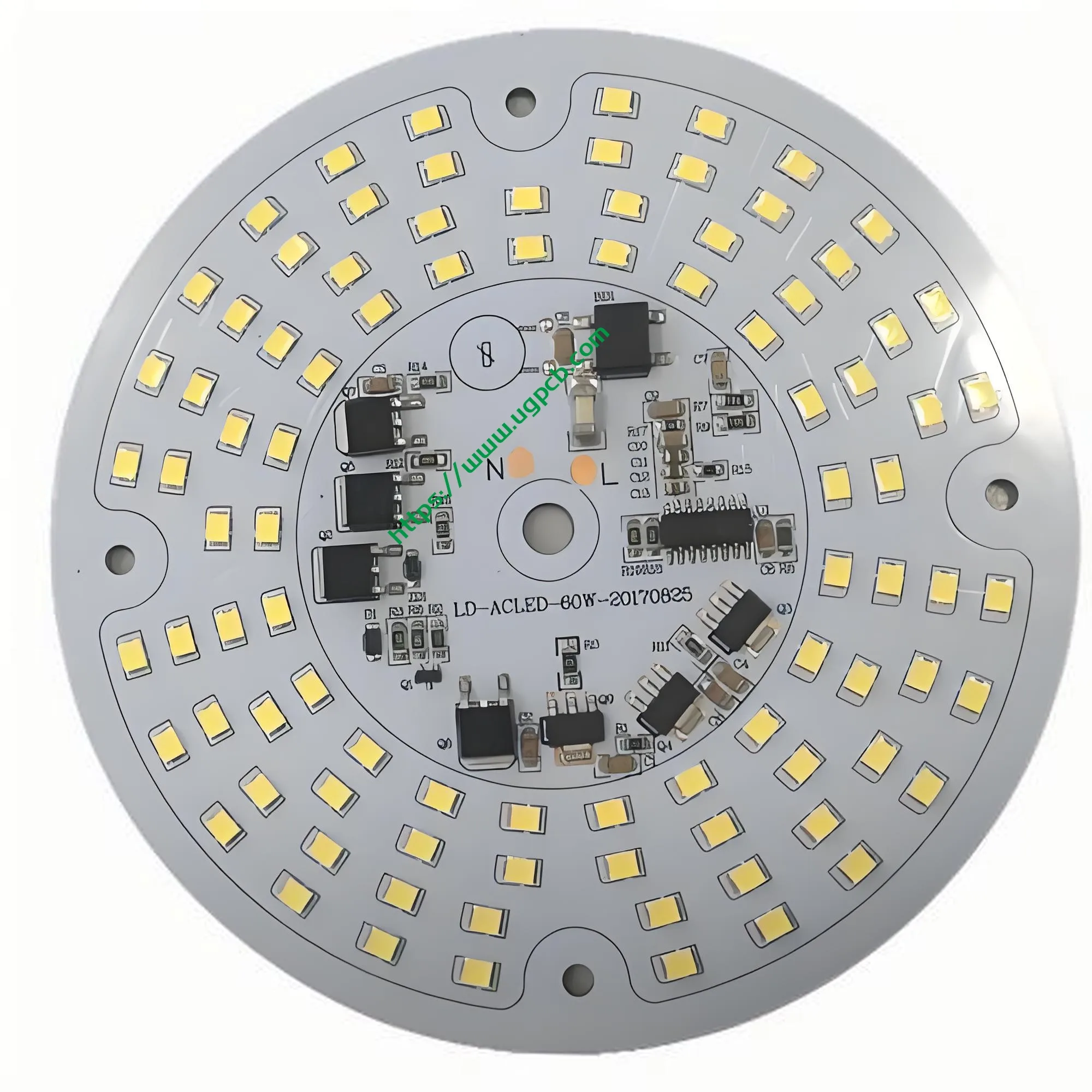

Classification

Les PCBA peuvent être classés en fonction de plusieurs critères:

- Par nombre de couches: Monoche, double couche, ou multicouche (y compris 1-2 couches)

- Par type de composants: À travers le trou, support de surface, ou une combinaison des deux

- Par matériel de substrat: FR-4, aluminium, cuivre, etc..

Matériels

Les matériaux principaux utilisés dans la construction d'un PCBA LED léger comprennent:

- Substrat: FR-4, aluminium, cuivre

- Traitement de surface: HASL sans plomb / OSP (Protection organique du solvant)

- Résister à la soudure: Blanc

- Épaisseur du cuivre: 0.5oz-2oz

- Couleur d'écran de soie: Noir

Performance

Les performances de ce PCBA se caractérisent par:

- Haute conductivité thermique en raison des couches de cuivre

- Faible perte de signal et intégrité élevée du signal

- Résistance aux facteurs environnementaux tels que l'humidité et les variations de température

- Conformité aux ROH et normes d'assemblage sans plomb

Structure

La structure d'un PCBA LED léger comprend généralement:

- Les traces de cuivre conductrice sur un substrat non conducteur

- Montage de surface et / ou composants à travers du trou Soudé sur le PCB

- Un masque de soudure blanc couvrant la couche supérieure pour la protection et l'identification

- Un écran de soie noir pour l'étiquetage et l'identification des composants

Caractéristiques

Les caractéristiques clés de ce PCBA incluent:

- Conception compacte et légère adaptée aux applications à contrainte d'espace

- Capacités de gestion thermique supérieures

- Durabilité et longévité améliorées dans divers environnements d'éclairage

- Compatibilité avec une large gamme de composants LED

Processus de production

Le processus de production d'un PCBA LED léger implique plusieurs étapes:

- Conception: Utilisation d'un logiciel spécialisé pour créer la disposition du circuit et le placement des composants.

- Préparation des matériaux: Sélection et préparation du substrat, feuille de cuivre, et autres matériaux.

- Empilement de calques: Empiler les couches de cuivre et de matériaux diélectriques.

- Via le forage: Forage des trous à travers les couches empilées pour vias (le cas échéant).

- Placage: Planter les vias avec le cuivre pour assurer la connectivité électrique.

- Gravure: Retirer l'excès de cuivre pour former le motif de circuit souhaité.

- Placement des composants: Montage de surface de soudage et / ou composants de trou à travers sur le PCB.

- Essai: Effectuer des tests rigoureux pour assurer la fonctionnalité et le respect des normes.

- Inspection finale: Assurer le PCBA répond à tous les critères de qualité et de performance.

Cas d'utilisation

Les cas d'utilisation courants pour le LED léger PCBA incluent:

- Éclairage résidentiel et commercial où l'efficacité énergétique et la longévité sont cruciales

- Systèmes d'éclairage automobile nécessitant une haute fiabilité et des performances

- Éclairage de signalisation et d'affichage dans les applications de vente au détail et publicitaire

- Projets d'éclairage décoratifs et architecturaux nécessitant des conceptions personnalisées et une esthétique élevée

Conclusion

Le PCBA LED léger est une solution avancée et fiable pour diverses applications d'éclairage LED. Sa conception compacte, Matériaux à haute performance, et la conformité aux normes de l'industrie en font un choix idéal pour les ingénieurs et les fabricants à la recherche de solutions électroniques efficaces et durables.

LOGO UGPCB

LOGO UGPCB