Introduction to Mini LED

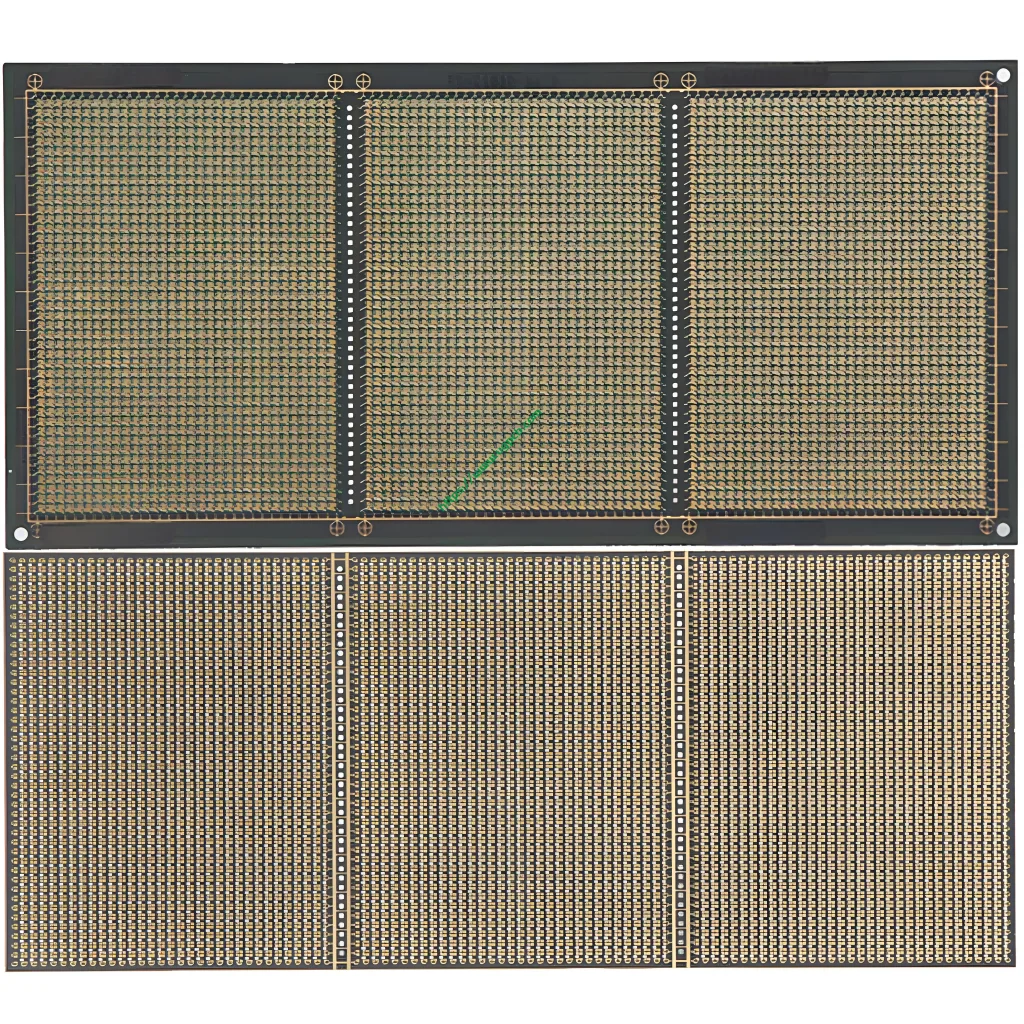

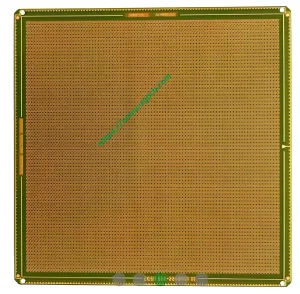

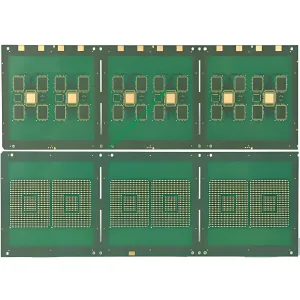

Mini LED, also known as “sub-millimeter light-emitting diode,” refers to an LED with a grain size of about 100 microns, first proposed by Jingdian. It falls between traditional LED and Micro LED, representing an improved version of traditional LED backlight.

Advantages of Mini LED Over Micro LED

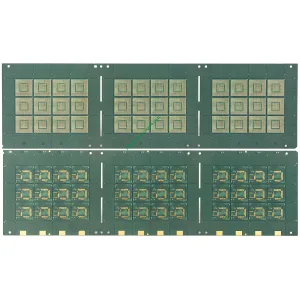

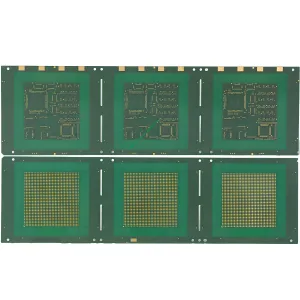

Compared with Micro LED, Mini LED boasts a higher yield rate, special-shaped cutting characteristics, and the ability to achieve a high-curved backlight form with a flexible substrate. It adopts a local dimming design and offers better color rendering, leading to more refined HDR partitions and a thickness close to OLED. Mini LED can save up to 80% of power, making it ideal for backlight applications such as power-saving, thinner, HDR, and special-shaped displays. It suits mobile phones, TVs, car panels, gaming laptops, and other products.

Technical and Economic Comparison with Micro LED

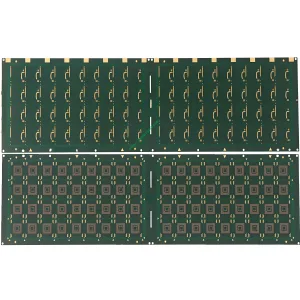

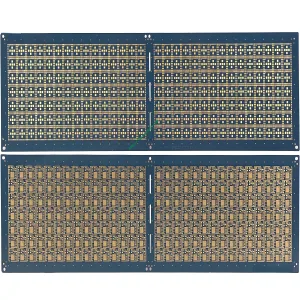

Mini LED is theoretically less technically difficult and easier to mass produce than Micro LED. It can tap into the vast LCD backlight market and offer a more economical product. Industry estimates suggest that an LCD TV panel with a Mini LED backlight design costs only about 60% à 80% of an OLED TV panel, while brightness and picture quality are similar, with higher power-saving efficiency. A 55-inch Mini LED backlight LCD panel uses 40,000 LEDs, aiding LED die manufacturers in reducing production capacity.

Future Prospects for Mini LED

While Micro LED promises a qualitative improvement in picture quality and represents the next generation of revolutionary display technology, current technology is still not mature enough. Mini LED, an improved version of LED backlight, can significantly enhance the effect of existing LCD screens at a relatively controllable cost, potentially becoming the mainstream in the market. Manufacturers are expected to accelerate research and development to bring Micro LED and Mini LED TV products to ordinary consumers.

Other Display Technologies: OLED and QLED

OLED: Revolutionary Display Technology

| OLED can self-illuminate in three primary colors, eliminating the need for a backlight module and liquid crystal. It reacts quickly, controlled directly by electric controls, unlike liquid crystal screened out by white light. OLED is energy-efficient, emitting only the desired color light without constant backlight emission blocked by liquid crystals. | |

| QLED: Quantum Dot Display Technology |

Quantum dots emit light of different wavelengths when stimulated by blue light, creating white light with the appropriate ratio of red and green quantum dots. The light excited by quantum dots is very “pure,” offering a subversive color gamut compared to ordinary LEDs with “turbid” contrast. Cependant, QLED is challenging and more unstable than OLED, requiring placement on a backlight module with blue light stimulating “pure” white light. Electroluminescence improves QLED stability, directly emitting “pure” white light excited by quantum dots.

Mini LED Applications

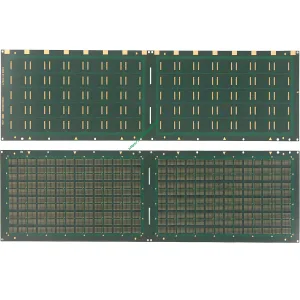

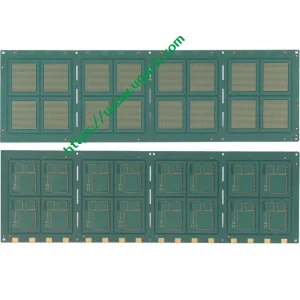

Mini LED Applications in Display Technology

| Mini LED serves dual purposes: as a direct-type white light backlight module and as an upgrade within the OLED technology chain, smaller than OLED but larger than Micro LED. These two types of Mini LED can be clearly distinguished. |

LOGO UGPCB

LOGO UGPCB