Fonction

Communication function: support GPRS and SMS dual-channel data transmission; support multi-center data communication.

Usage function: collect serial device data, such as serial instrument, collector, CLu, etc..

Remote management function: support remote parameter setting, program upgrade

Caractéristiques

Industrial-grade design, suitable for harsh outdoor environment.

Built-in software and hardware watchdog, no crash, no disconnection.

Support data transparent transmission.

Support domain name resolution function.

Support various configuration software and users to develop their own software system.

Avantages

En comparaison, the use of wireless data transmission module to establish a dedicated wireless data transmission method has the following advantages over other methods. The following introduces the advantages of using DATA-6106 wireless data transmission module to establish a dedicated wireless data transmission method compared to wired communication.

Cheap

The establishment of wired communication requires the laying of cables or the excavation of cable trenches, which requires a lot of manpower and material resources; while the use of wireless data transmission stations to establish a dedicated wireless data transmission method does not require the laying of cables or the excavation of cable trenches, but only requires connections at each terminal. Wireless data transmission stations and antennas of appropriate heights can be set up. En revanche, the use of wireless data transmission modules to establish a dedicated wireless data transmission method saves manpower and material resources, and the investment is also quite economical.

Bien sûr, in some close-range data communication systems, wireless communication is not cheaper than wired methods, but sometimes the actual on-site environment is difficult to wire, and customers still choose wireless methods to achieve communication according to their needs. The needs of the on-site environment.

Short construction period

When it is necessary to connect and communicate with remote sites from several kilometers to tens of kilometers away, the use of wired methods requires the installation of long-distance cables or the excavation of long cable trenches. This project cycle may take several months. The use of data transmission modules to establish a dedicated wireless data transmission method only requires the installation of antennas of appropriate heights, and the engineering cycle only takes a few days or weeks. En revanche, wireless methods can quickly establish communication links, greatly shortening the project cycle

Good adaptability

The limitations of wired communications are too great. When encountering some special application environments, such as special geographical environments such as mountains, lakes, and forests, or application environments where wiring is difficult such as moving objects, wired networks will be restricted. Wiring engineering has extremely strong constraints. Using wireless data transmission modules to establish a dedicated wireless data transmission method will not be subject to these restrictions. Donc, using wireless data transmission modules to establish a dedicated wireless data transmission method will have better and wider coverage than using wireless data transmission modules to establish a dedicated wireless data transmission method. Wired communication. Adaptability is almost not limited by the geographical environment.

Good scalability

After establishing a communication network, users often add new equipment due to system needs. If a wired method is used, rewiring is required, the construction is more troublesome, and the original communication line may be damaged. Cependant, if a wireless data transmission station is used to establish a dedicated wireless data transmission method, it is only necessary to connect the new device to the wireless data transmission station. The expansion of the system can be achieved through mutual connection, which has better scalability in comparison.

Technical parameters

Data format: 8 data bits, 1 stop bit, parity bit (odd, even, none) can be set.

Baud rate: 300, 600, 1200, 2400, 4800, 9600, 19200 (Bit/S) optional.

Communication error code: ≤10.

Alimentation: 10V~30V DC.

Average current: <70mA/12V.

Working environment: Temperature: -40~+85℃; Humidity: ≤95%.

Data transmission

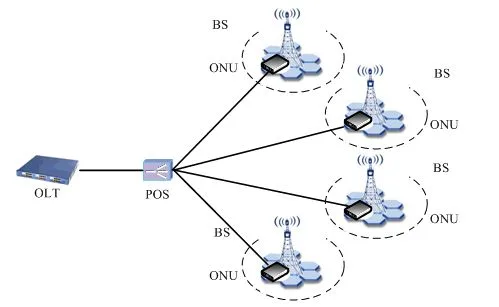

Data transmission can be simply divided into two categories: wired (including laying optical cables, cables or renting telecommunications lines) and wireless (divided into establishing a dedicated wireless data transmission system (433MHZ frequency band and 2.4G frequency band) or borrowing CDPD, GSM, CDMA and other public network information platforms).

Application field

Wireless communication modules are widely used in vehicle monitoring, télécommande, telemetry, small wireless networks, wireless meter reading, access control systems, community paging, industrial data acquisition systems, wireless tags, identity recognition, contactless radio frequency smart cards, small wireless data terminals, security and fire protection systems, wireless remote control systems, biological signal acquisition, hydrological and meteorological monitoring, robot control, wireless 232 data communication, wireless 485/422 data communication, digital audio, digital image transmission and other fields.

Application:

The first thing users care about is the transmission distance, but distance is not a problem. The near end uses the 433MHz frequency band wireless data terminal DTD433, and the far end uses the GPRS transparent data terminal DTP_S09F. The so-called “near” means that most factories and mines can be covered within 3 kilometers; the so-called “far” means that the communication distance exceeds 3 kilometers, even across different regions and countries. Heureusement, China Mobile’s network has covered the world, and distance is not a problem. The combination of DTP_S09F and DTD433 can meet most wireless measurement and control requirements.

Wireless communication solution between multiple PLCs

Design instructions for wireless MODBUS communication between multiple Siemens S7_200s, with design instructions and programs for PLC master and slave machines.

Wireless N:N communication design between multiple Mitsubishi PLCs, Inovance PLC and Mitsubishi PLC have the same solution.

MODBUS wireless communication routine between two Delta PLCs, program source code and design instructions. ◆Connection application of wireless PLC data terminal and wireless MODBUS measurement and control terminal

PLC and 4DI/4DO wireless switch terminal DTD433H and 4AI/4AO wireless analog terminal DTD433F within 3 kilometers perform wireless communication using MODBUS protocol to realize wireless MODBUS transmission. ◆Wireless communication solution between touch screen and PLC

Wireless communication between Siemens 200PLC and wireless PLC data terminal and Shenzhen Buke touch screen;

Wei Lun touch screen and S7-200 wireless PPI communication;

Kunlun Tongtai touch screen MCGS and PLC wireless communication;

Autoface touch screen and Siemens PLC wireless MODBUS communication;

Display and control touch screen wireless communication example

When running the touch screen configuration program, you can use MODBUS protocol, Siemens PPI protocol, Mitsubishi N:N protocol, Yonghong PLC protocol, Delta PLC protocol, etc.. ◆Configuration software and PLC wireless communication solution

Configuration King software and Siemens PLC wireless PPI, MODBUS communication;

Force control configuration software and Siemens PLC wireless communication;

Preventive measures

The module must be modulated to work properly. Common fixed code encoding devices such as PT2262/2272 can be directly connected, which is very simple. Because it is a dedicated encoding chip, the effect is very good and the transmission distance is very long.

Another important use of this module is to cooperate with the microcontroller to realize data communication. A cette époque, there are certain skills:

- Reasonable communication speed

The maximum transmission data rate of the data module is 9.6KBs, which is generally controlled at around 2.5k. If the data rate is too high, it will reduce the receiving sensitivity, increase the bit error rate, and even fail to work at all.

- Reasonable information encoding format

When the microcontroller and the module are working, they usually define the transmission protocol themselves. Regardless of the modulation method used, the format of the transmitted information encoding is very important, which directly affects the reliable transmission and reception of data.

Code group format recommendation

Preamble + synchronization code + data frame, the length of preamble should be greater than 10ms to avoid background noise, because the first bit of data received by the receiving module is easily interfered (c.. zero-level interference), and the received data is wrong. Donc, CPU encoding and decoding can add some garbled codes before the data identification bit to suppress zero-level interference. The synchronization code is mainly used to distinguish between the preamble and data. It has certain characteristics, so that the software can identify the synchronization code through certain algorithms and prepare for receiving data at the same time.

Do not use non-return-to-zero code for data frames, let alone long 0 and long 1. Use Manchester code or POCSAG code, etc..

Interference of single-chip microcomputer on receiving module

When MCU simulates 2262, it is generally normal. Cependant, when the single-chip microcomputer simulates 2272 decoding, it is usually found that the remote control distance is shortened a lot. This is because the multiplication of the MCU clock frequency will interfere with the receiving module. The electromagnetic interference of the 51 series microcontroller is relatively large. 2051 is slightly smaller, and the PIC series is relatively small. We need to take some anti-interference measures to reduce interference. Par exemple, the microcontroller and the remote control receiving circuit are powered by two 5V power supplies respectively, the receiving board is powered by a single-chip 78L05, the microcontroller clock area is far away from the receiving module, the operating frequency of the microcontroller is reduced, and a shield is added in the middle.

It is best to make an isolation circuit when the receiving module is interfaced with the 51 series microcontroller, so that the electromagnetic interference of the microcontroller to the receiving module can be better curbed.

When the receiving module is working, it generally outputs high-level pulses, not DC levels, so it cannot be tested with a multimeter. During debugging, a light-emitting diode and a 3K resistor can be connected in series to monitor the output status of the module.

When the wireless data module is used in conjunction with special codec chips such as PT2262/PT2272, the connection is very simple. Just connect directly, and the transmission distance is relatively ideal, generally up to 600 meters or more. The clock interference caused by the transmission distance is significantly reduced, and the general practical distance is within 200 meters.

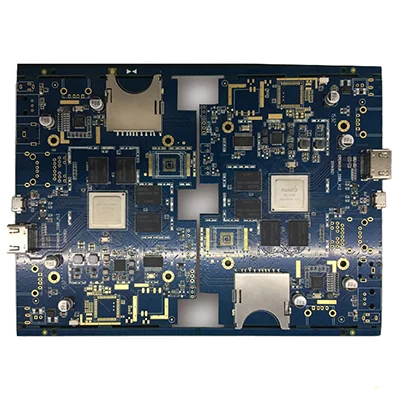

UGPCB provides Netcom prototype PCB assembly, short delivery time, professional one-stop PCBA service, welcome to call for consultation

LOGO UGPCB

LOGO UGPCB