Introduction to Rancangan PCBA for Automotive Control Systems

The Rancangan PCBA for automotive control systems is a specialized printed circuit board assembly designed specifically for use in vehicles. It integrates various electronic components to manage and control different functionalities within a car, ensuring optimal performance and reliability.

What is Rancangan PCBA?

Rancangan PCBA refers to the complete assembly of printed circuit boards tailored for automotive applications. These assemblies are meticulously designed to meet the stringent requirements of the automotive industry, including durability, haute performance, and resistance to harsh environmental conditions.

Comment ça marche?

The PCBA works by providing a platform for electronic components to be interconnected through conductive pathways on the PCB. These components include microcontrollers, capteurs, actionneurs, and other critical parts that together form the control system for various automotive functions. The PCBA ensures that these components communicate effectively and efficiently, enabling seamless operation of the vehicle’s systems.

Applications and Purpose

Rancangan PCBAs are used in a variety of automotive control systems such as engine management, infotainment systems, advanced driver-assistance systems (ADAS), et plus. Their primary purpose is to enhance vehicle performance, sécurité, and user experience by integrating complex electronic systems into a cohesive unit.

Types of Automotive PCBAs

There are generally two main types of automotive PCBAs:

- Engine Control Unit (ECU) PCBAs: Specifically designed for managing the engine’s performance and efficiency.

- Infotainment System PCBAs: Used for controlling the vehicle’s entertainment and information systems.

- ADAS PCBAs: Support advanced driver-assistance features like lane-keeping assist, adaptive cruise control, etc..

Composition des matériaux

The substrate of the Rancangan PCBA typically consists of TG and TG170 within an FR-4/TG high material, known for its excellent thermal stability and mechanical strength. This makes it ideal for withstanding the high temperatures and vibrations experienced in automotive environments.

Caractéristiques de performance

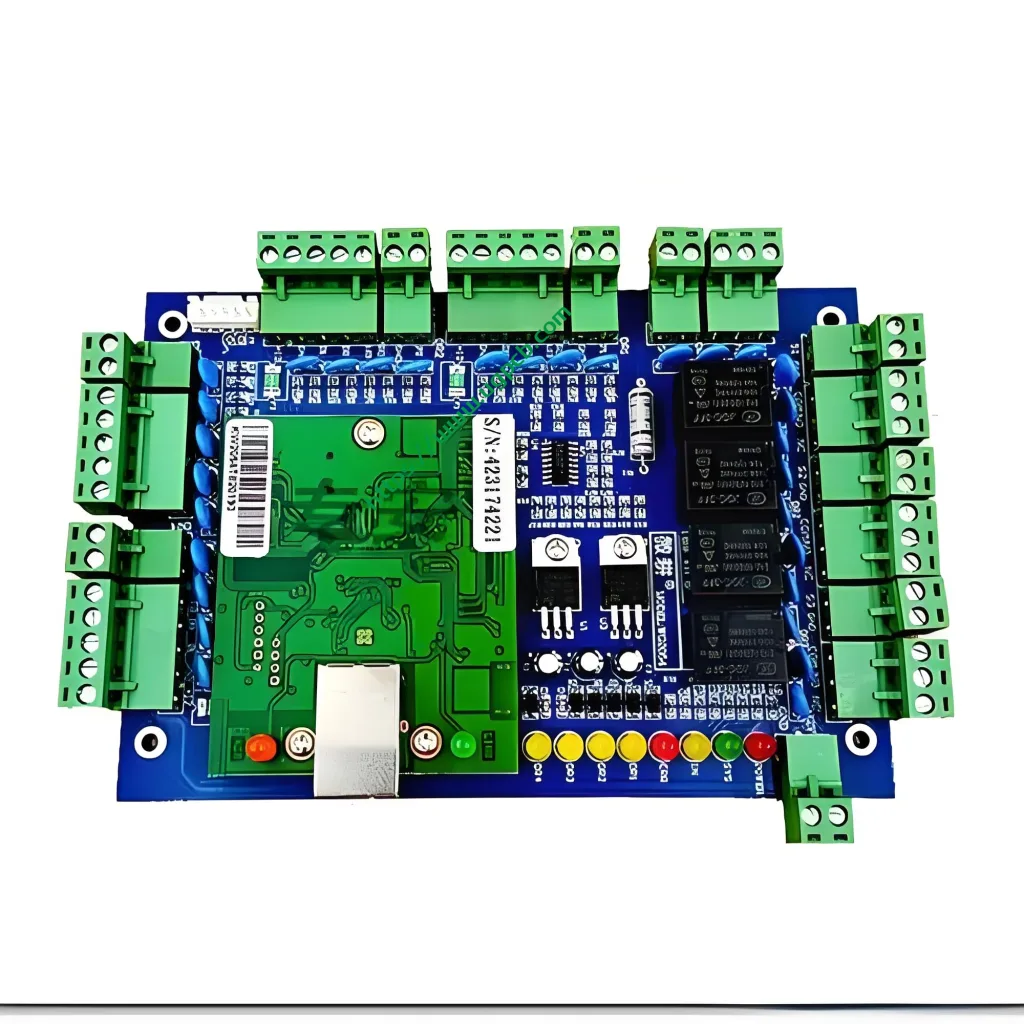

These PCBAs feature up to 12 couches, allowing for complex designs and high-density interconnections. The surface finish options include HASL lead-free and immersion gold, which provide superior solderability and corrosion resistance. Copper thickness ranges from 0.5oz to 6oz, depending on the application requirements.

Caractéristiques structurelles

The PCBAs come in various colors including green, noir, blanc, rouge, and blue, catering to different aesthetic and identification needs. They undergo rigorous testing at both the PCB and PCBA levels to ensure quality and reliability.

Processus de production

The production process involves several key steps:

- Conception: Using specialized software to create the layout and ensure all components are accurately placed.

- Sélection des matériaux: Choosing high-quality materials like FR-4/TG high for optimal performance.

- Layering: Stacking multiple layers of conductive material to form the PCB structure.

- Forage: Creating holes for through-hole components and vias.

- Placage: Applying surface finishes like HASL lead-free or immersion gold.

- Assemblée: Mounting components and connectors onto the PCB.

- Essai: Conducting thorough tests to verify the PCBA’s functionality and reliability.

Use Case Scenarios

Rancangan PCBAs are primarily used in:

- Automotive Manufacturing Plants: For in-house integration of new vehicle models.

- Aftermarket Suppliers: To offer upgraded control systems for existing vehicles.

- Research and Development Centers: For experimenting with new automotive technologies.

En conclusion, the Rancangan PCBA for automotive control systems is an essential component in modern vehicles, offering enhanced performance, sécurité, and user experience. Its advanced design, high-quality materials, and rigorous production process make it a preferred choice for ensuring the highest standards of quality and reliability in the automotive industry.

LOGO UGPCB

LOGO UGPCB