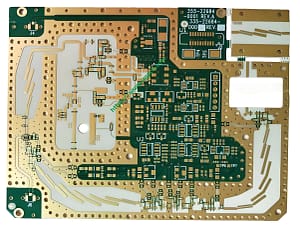

Aperçu de Rogers 5880 PCB

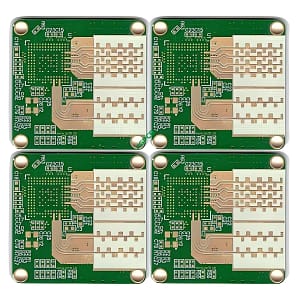

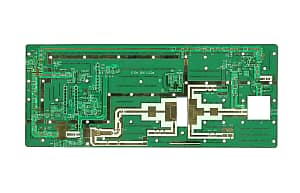

Les Roger 5880 Le PCB est un produit haute performance circuit imprimé conçu pour les applications exigeantes en micro-ondes, instrumentation, et communication. Utiliser Rogers 5880 substrat, ce produit offre une intégrité et une fiabilité de signal exceptionnelles. Avec des constantes diélectriques de 2.2 et options d'épaisseur allant de 0,2 mm à 4,8 mm, il offre une flexibilité pour diverses exigences de conception. Le traitement de surface est Immersion Gold, assurant une excellente soudabilité et une excellente résistance à la corrosion. Les procédés spéciaux incluent le Téflon carte PCB multicouche et PCB fraisé, améliorant ses performances dans les applications haute fréquence.

Définition et spécifications clés

Un Rogers 5880 Le PCB est défini par son utilisation du Rogers 5880 substrat, connu pour sa faible constante diélectrique et sa haute fidélité du signal. La constante diélectrique est 2.2, ce qui est idéal pour maintenir l'intégrité du signal à haute fréquence. L'épaisseur peut varier de 0,2 mm à 4,8 mm, permettant la personnalisation en fonction des besoins d'application spécifiques. Le traitement de surface est Immersion Gold, Fournir une finition robuste et fiable. Le poids de cuivre de base est de 0,5 oz, avec une épaisseur finie de 1 oz, Assurer une conductivité efficace. Des processus spéciaux tels que le multicouche en téflon et la coussin améliorent encore les performances du PCB dans des environnements à haute fréquence.

Considérations de conception

Lors de la conception d'un Rogers 5880 PCB, Plusieurs facteurs doivent être pris en compte:

- Constante diélectrique: Le 2.2 Constante diélectrique de Rogers 5880 est optimal pour les signaux à haute fréquence, Réduire le retard et la perte.

- Épaisseur: La large gamme d'options d'épaisseur (0.2mm – 4.8mm) Permet une flexibilité dans la conception, Répondant à différentes exigences de demande.

- Épaisseur du cuivre: La base et les poids en cuivre fini garantissent que le PCB peut gérer des courants élevés et maintenir l’intégrité du signal.

- Traitement de surface: Immersion Gold offre une excellente soudabilité et protège contre la corrosion, essentiel pour une fiabilité à long terme.

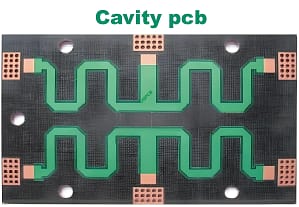

- Processus spéciaux: Des techniques telles que le multicouche de téflon et le fraisage sont cruciales pour améliorer les performances dans les applications haute fréquence et micro-ondes..

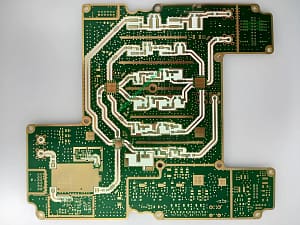

Principe de fonctionnement

Les Roger 5880 Le PCB fonctionne sur la base du principe d'impédance contrôlée et de perte de signal minimale. La faible constante diélectrique du substrat garantit que les signaux voyagent avec un retard et une perte minimes, maintenir leur intégrité. Le contrôle précis de l'épaisseur et du poids du cuivre permet une impédance constante, ce qui est essentiel pour la transmission des signaux haute fréquence. Le traitement de surface d'or de l'immersion fournit un point de connexion fiable pour les composants, Assurer un transfert de signal efficace.

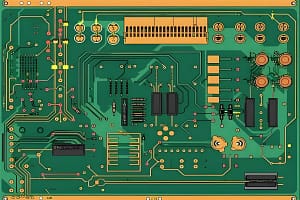

Applications

Rogers 5880 Les PCB sont utilisés dans une variété d'applications qui nécessitent des performances à haute fréquence et une intégrité du signal:

- Micro-ondes: Idéal pour les systèmes radar, communications par satellite, et d'autres applications micro-ondes où la pureté du signal est primordiale.

- Instrumentation: Utilisé dans les équipements de mesure et de test de précision où le traitement précis du signal est crucial.

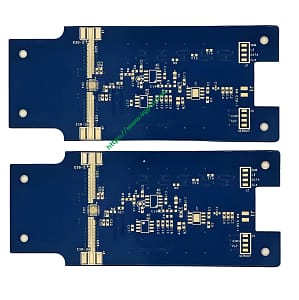

- Communication: Convient à la transmission de données à grande vitesse et à la réception dans les dispositifs de communication.

Classification

Rogers 5880 Les PCB peuvent être classés en fonction de plusieurs critères:

- Nombre de couches: Allant de 1 superposer 24 couches, en fonction de la complexité du circuit.

- Épaisseur: Les options de 0,2 mm à 4,8 mm permettent une personnalisation en fonction des besoins d'application spécifiques.

- Processus spéciaux: Versions standard et spécialisées, tels que ceux qui utilisent des techniques multicouches ou de contre-diat.

Propriétés des matériaux

Les propriétés clés des Rogers 5880 Le substrat comprend:

- Faible constante diélectrique: Assure un délai et une perte de signal minimal, Le rendre adapté aux applications à haute fréquence.

- Grande gamme d'épaisseur: Permet une flexibilité dans la conception, Répondant à différentes exigences de demande.

- Excellente soudabilité: Le traitement de surface d'or de l'immersion offre un point de connexion fiable et robuste pour les composants.

- Fidelité élevée du signal: Maintient l'intégrité du signal même aux hautes fréquences, Assurer des performances fiables.

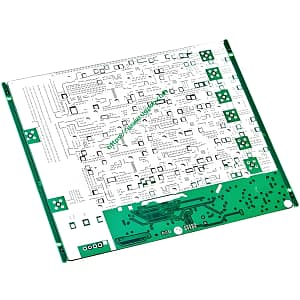

Processus de production

La production d'un Rogers 5880 PCB implique plusieurs étapes:

- Sélection des matériaux: Choisir les Rogers 5880 substrat pour sa faible constante diélectrique et sa fidélité à signal élevé.

- Conception de circuit: Création de la disposition du circuit avec des considérations pour les performances à haute fréquence et l'intégrité du signal.

- Gravure: Suppression du cuivre inutile pour créer le modèle de circuit souhaité.

- Laminage: Collage de plusieurs couches ensemble sous haute pression et température pour garantir une connexion solide et fiable.

- Finition des surfaces: Application d'Immersion Gold pour améliorer la soudabilité et la résistance à la corrosion.

- Processus spéciaux: Utilisation de techniques telles que le multicouche de téflon et le fraisage pour améliorer encore les performances dans les applications haute fréquence.

- Tests et contrôle qualité: S'assurer que le produit final répond à toutes les spécifications et normes.

Utiliser des scénarios

Rogers 5880 Les PCB sont utilisés dans des scénarios où les performances haute fréquence et l'intégrité du signal sont critiques:

- Systèmes de communication par micro-ondes: Assurer une transmission claire et fiable des signaux dans les systèmes de communication radar et par satellite.

- Instruments de mesure de précision: Fournir un traitement du signal précis et fiable dans les équipements de mesure scientifiques et industriels.

- Communication de données à grande vitesse: Faciliter un transfert de données rapide et fiable dans les dispositifs de communication modernes.

En résumé, les Rogers 5880 PCB est un circuit imprimé haute performance conçu pour les applications exigeantes dans les micro-ondes, instrumentation, et communication. Sa faible constante diélectrique, grande gamme d'épaisseur, et une excellente fidélité du signal en fait un choix idéal pour maintenir l'intégrité du signal à haute fréquence.

LOGO UGPCB

LOGO UGPCB