Composition des matériaux

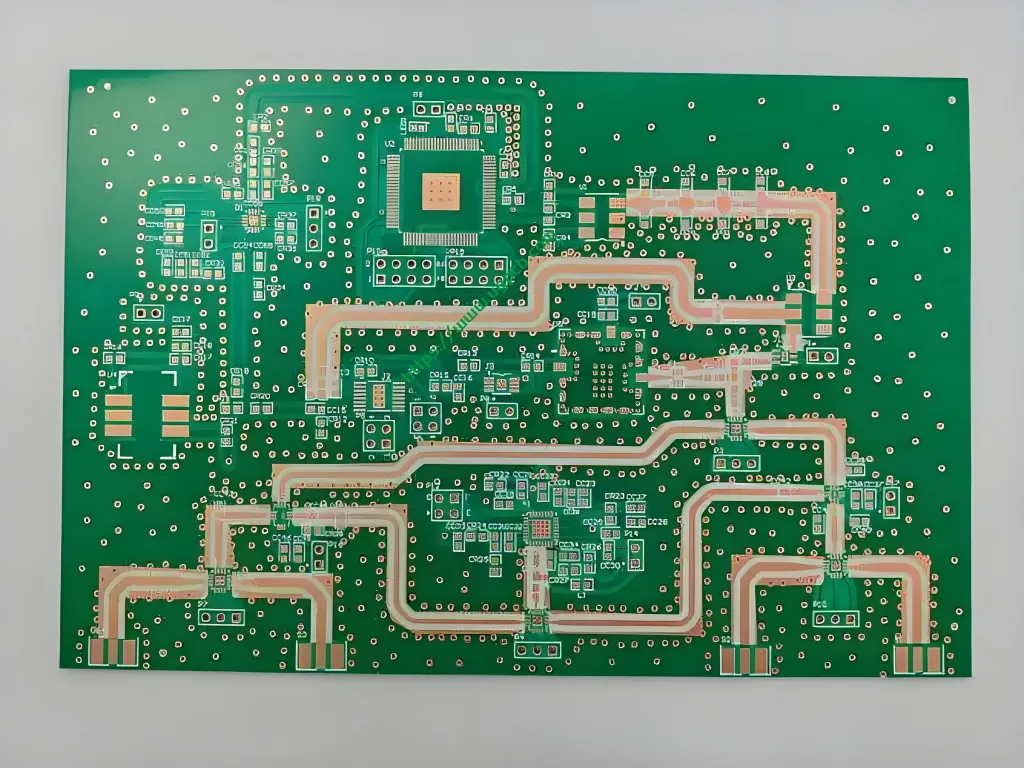

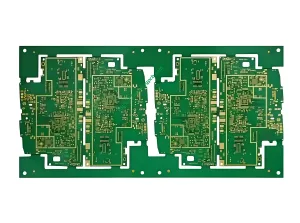

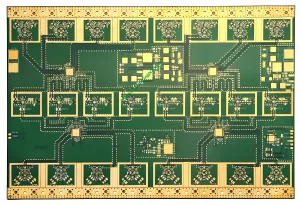

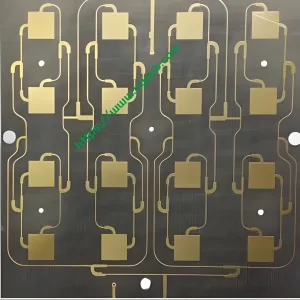

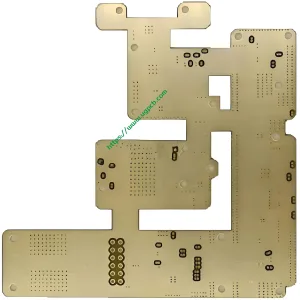

The Rogers RO4350B + FR4 Hybrids Printed Circuit Board is a unique blend of Rogers RO4350B and FR4 materials. The board structure consists of two layers of Rogers RO4350B, sandwiching two layers of FR4, creating a four-layer PCB. This hybrid design leverages the high-performance characteristics of Rogers RO4350B and the cost-effectiveness of FR4, offering a balanced solution for various applications.

Performance Specifications

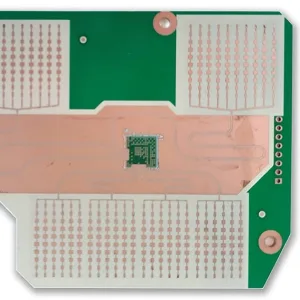

The Rogers RO4350B + FR4 Hybrids Printed Circuit Board boasts a dielectric constant (NSP) de 3.48, which is essential for maintaining signal integrity in high-frequency applications. The finished thickness of the board is 1.0mm, with a dielectric thickness of 0.254mm. The material copper thickness is ½(18µm) HH / HH, and the finished copper thickness is 1/0.5/0.5/1 ounce per square foot (once), providing ample conductivity for electrical signals.

Processus de production

The production of the Rogers RO4350B + FR4 Hybrids Printed Circuit Board involves several key steps. Premièrement, the Rogers RO4350B and FR4 materials are carefully prepared and layered according to the specified design. Suivant, the layers are pressed together under controlled conditions to ensure uniform thickness and bonding. After that, drilling and routing are performed to create the necessary circuits and component holes. The board is then plated with copper to achieve the desired copper thickness, followed by surface treatment with immersion gold to enhance corrosion resistance and conductivity.

Scénarios d'application

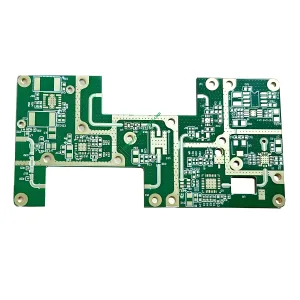

The Rogers RO4350B + FR4 Hybrids Printed Circuit Board is ideal for communication PCBs due to its high-frequency performance and cost-effectiveness. It can be used in various communication devices, such as radios, base stations, and other electronic equipment that require stable and reliable signal transmission. The board’s hybrid design ensures that it meets the demanding requirements of modern communication systems while keeping costs manageable.

Traitement de surface

The surface of the Rogers RO4350B + FR4 Hybrids Printed Circuit Board is treated with immersion gold, which not only enhances its corrosion resistance but also improves its electrical conductivity. This treatment ensures that the board maintains optimal performance over time, even in harsh environments.

Overall, the Rogers RO4350B + FR4 Hybrids Printed Circuit Board is a versatile and high-performance PCB solution that is well-suited for a wide range of communication applications.

LOGO UGPCB

LOGO UGPCB