Aperçu

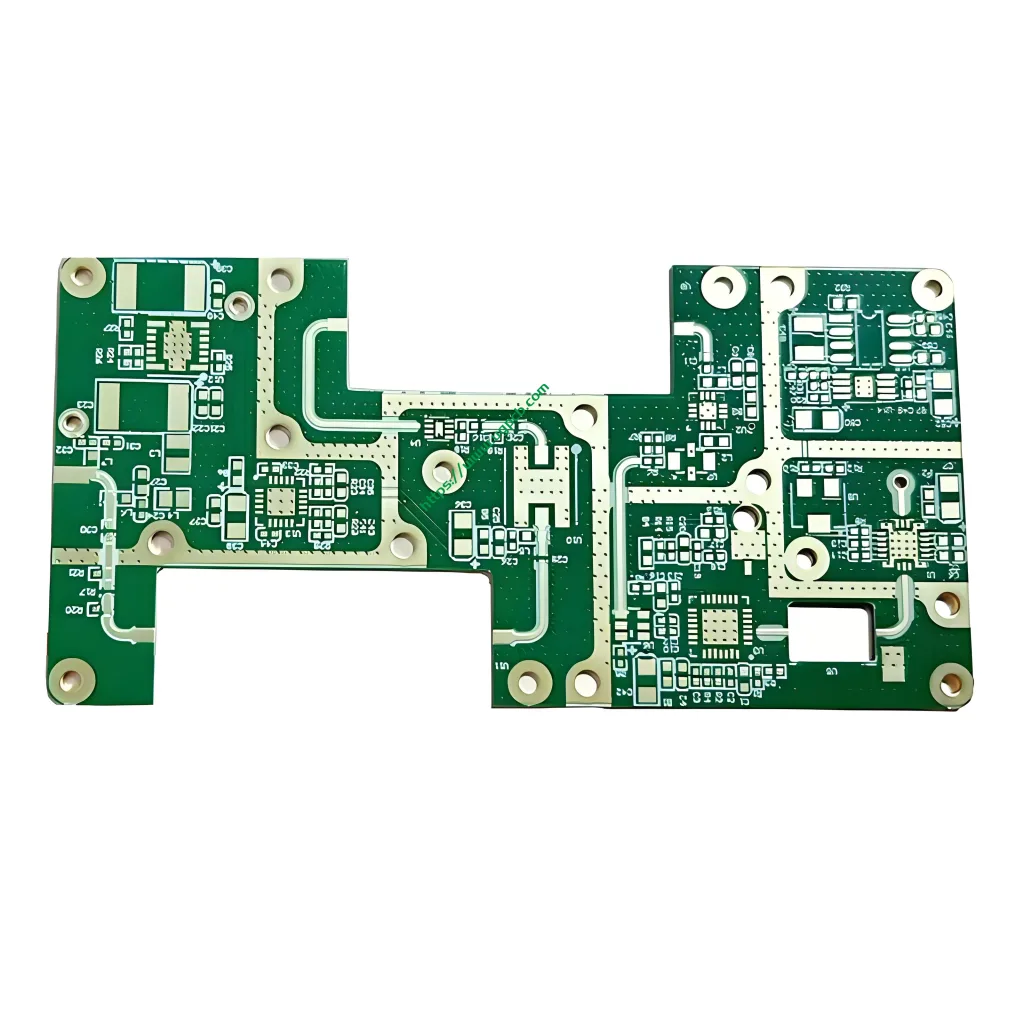

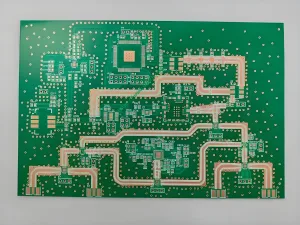

The RO4350B + IT180 Mix Laminate High Frequency PCB is a specialized electronic component designed for high-performance applications in the communication industry. Combining the robustness of traditional FR4 materials with the advanced properties of Rogres RO4350B, this 4-layer PCB offers exceptional electrical performance and reliability.

Composition des matériaux

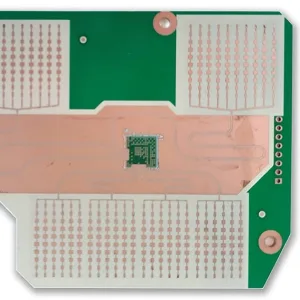

The PCB is constructed using a unique blend of materials:

- Core Material: Rogres RO4350B, a high-frequency, low-loss laminate with a dielectric constant (NSP) de 3.48. This material is known for its stability and low moisture absorption, making it ideal for high-speed digital and microwave applications.

- Support Layers: Two layers of FR4, a standard fiberglass-reinforced epoxy laminate, provide structural support and cost-effectiveness.

Layer Configuration

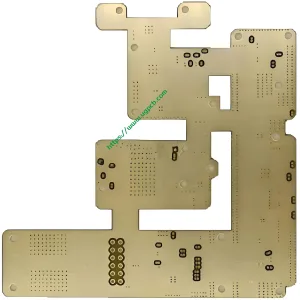

The PCB features a 4-layer configuration:

- Total Thickness: 1.0mm

- Épaisseur diélectrique: 0.508mm for the RO4350B layers

- Épaisseur du cuivre: 1/0.5/0.5/1 ounce per square foot (once), ensuring optimal conductivity and current carrying capacity.

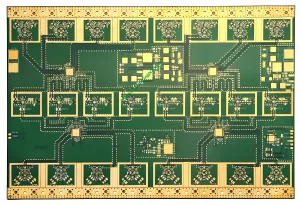

Caractéristiques de performance

The RO4350B + IT180 Mix Laminate High Frequency PCB offers several key performance benefits:

- Low Loss: The RO4350B material minimizes signal loss, ensuring clear and accurate transmission over high frequencies.

- Constante diélectrique stable: The consistent DK of 3.48 across temperature and humidity changes maintains signal integrity.

- Haute fiabilité: The combination of RO4350B and FR4 provides a durable and reliable PCB suitable for demanding applications.

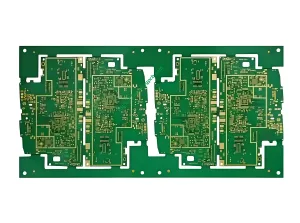

Processus de production

The production of the RO4350B + IT180 Mix Laminate High Frequency PCB involves several precision steps:

- Préparation des matériaux: RO4350B and FR4 materials are cut to size and prepared for lamination.

- Laminage: The layers are bonded together under controlled conditions to ensure uniform thickness and adhesion.

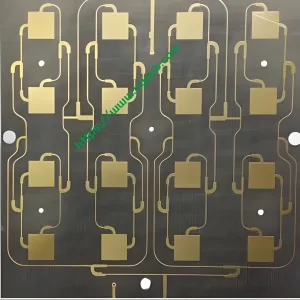

- Copper Cladding: Copper foil is applied to the outer layers to form the conductive circuits.

- Gravure: Unwanted copper is removed to create the desired circuit patterns.

- Placage: An immersion gold finish is applied to the copper surfaces for enhanced conductivity and corrosion resistance.

- Assemblage final: Components are mounted, and the PCB is tested to ensure it meets specifications.

Scénarios d'application

The RO4350B + IT180 Mix Laminate High Frequency PCB is ideal for a range of communication applications, y compris:

- Wireless Communication Systems: Base stations, antennas, and other components requiring high-frequency signal transmission.

- Radar: High-precision radar equipment that relies on low-loss materials for accurate signal detection and processing.

- Communications par satellite: Equipment that operates in extreme environments and requires reliable, high-speed data transmission.

Conclusion

The RO4350B + IT180 Mix Laminate High Frequency PCB is a versatile and high-performance component suitable for demanding communication applications. Its combination of advanced materials and precision manufacturing ensures reliable performance and long-term durability.

LOGO UGPCB

LOGO UGPCB